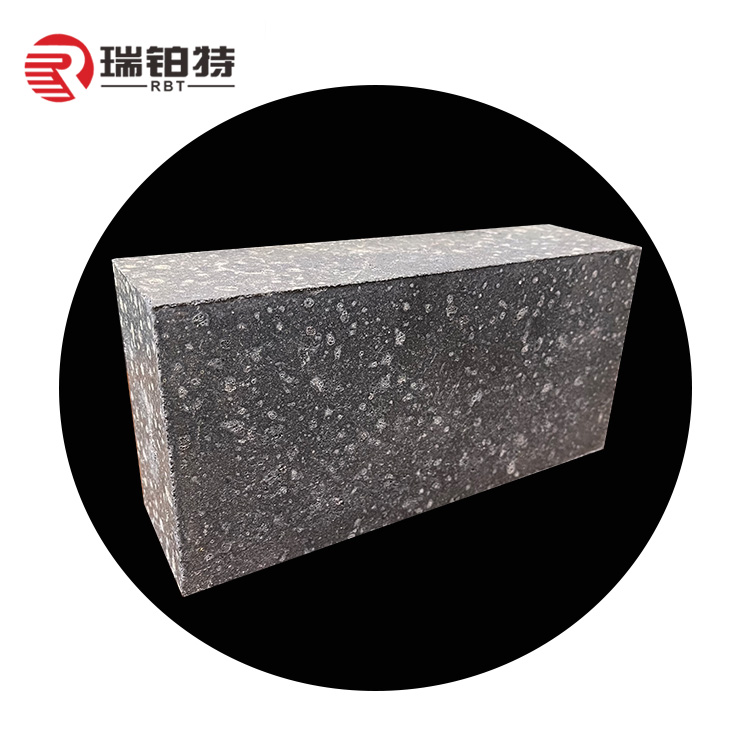

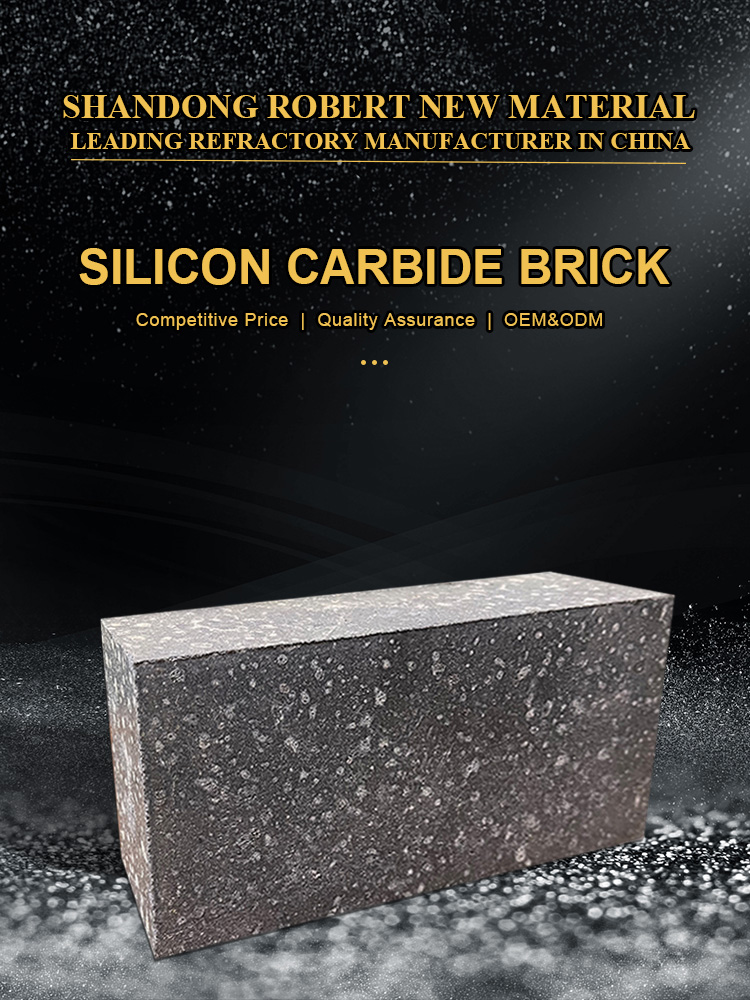

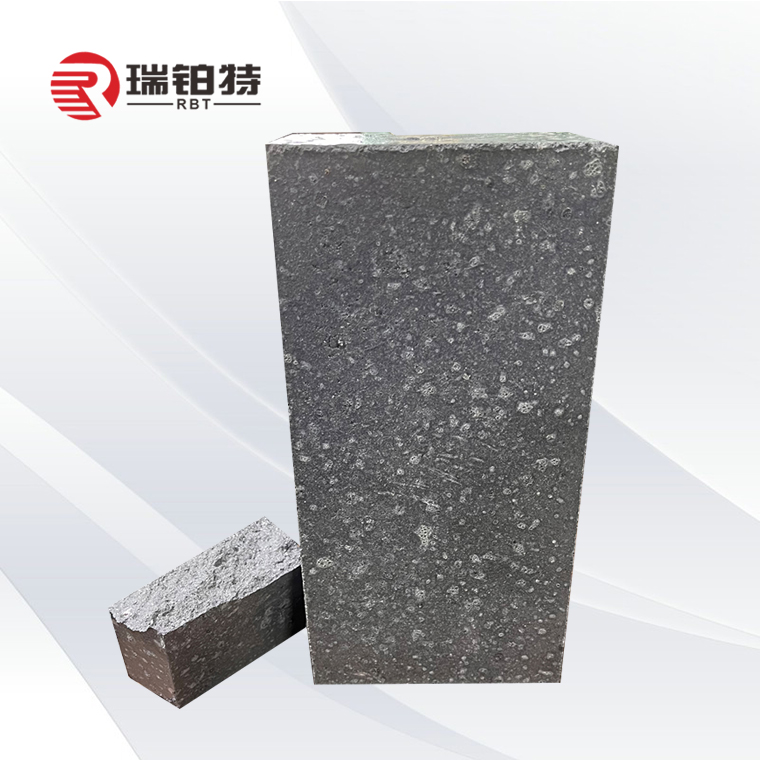

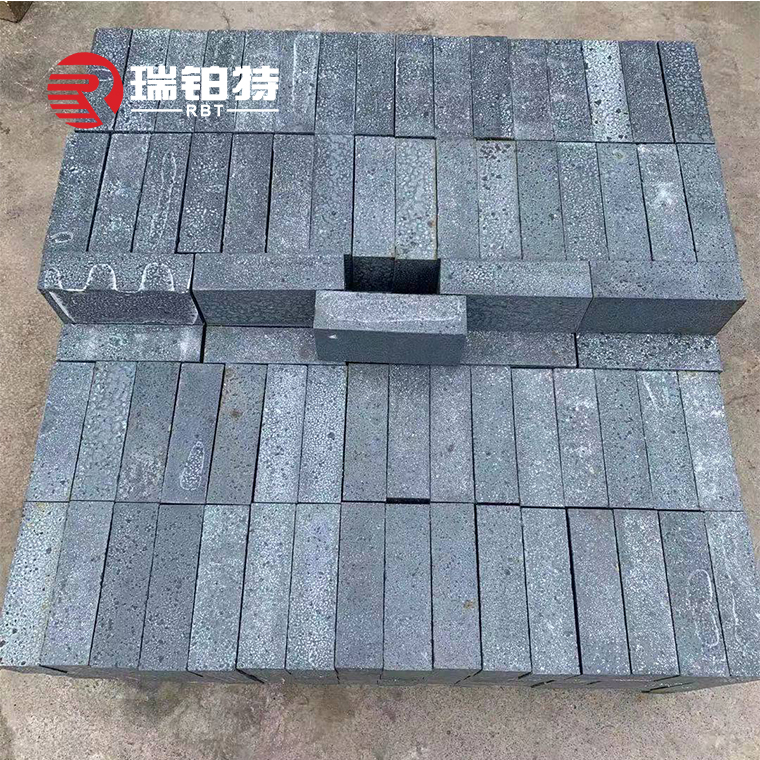

Silicon Carbide Cib

Cov ntaub ntawv khoom

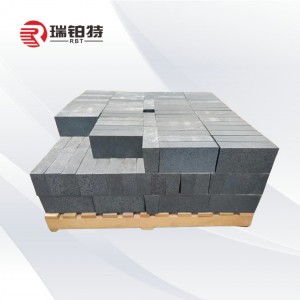

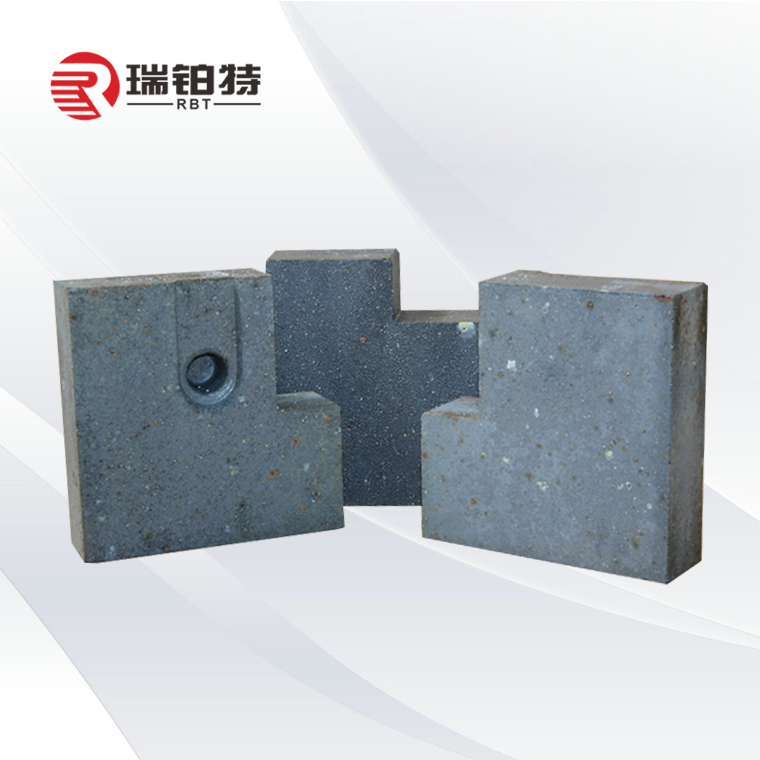

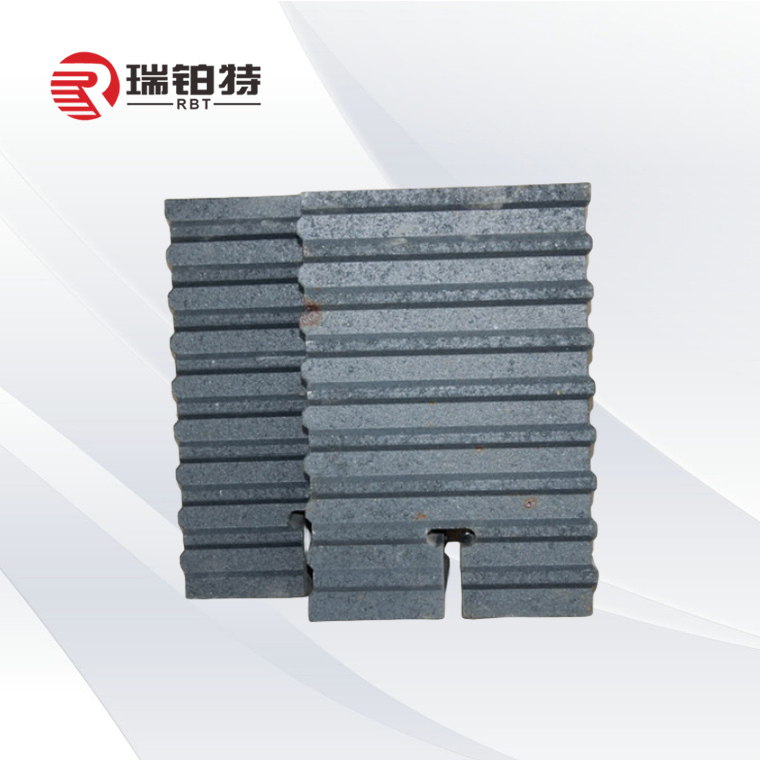

| KhoomLub npe | Silicon Carbide Cib |

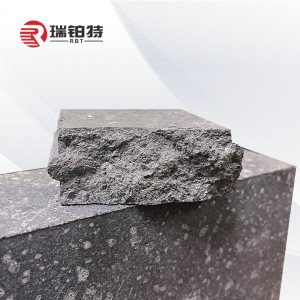

| Kev piav qhia | Silicon carbide bricks raws li silicon carbide ua cov ntaub ntawv tseem ceeb, oxide li binder firing ntawm refractory khoom. |

| Kev faib tawm | Av nplaum sintered, Si3N4 Sintered, Sialon sintered, β-SiC sintered, Si2ON2 sintered, Recrystallization |

| Loj | Standard loj: 230 x 114 x 65 mm, tshwj xeeb loj thiab OEM kev pab cuam kuj muab! |

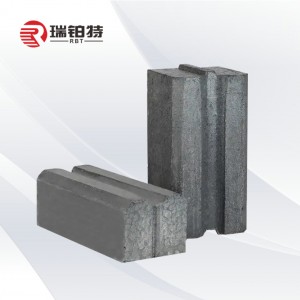

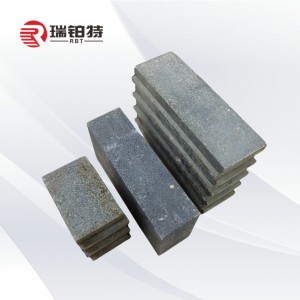

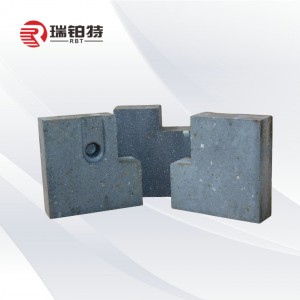

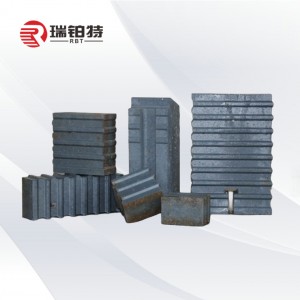

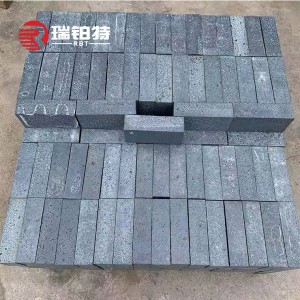

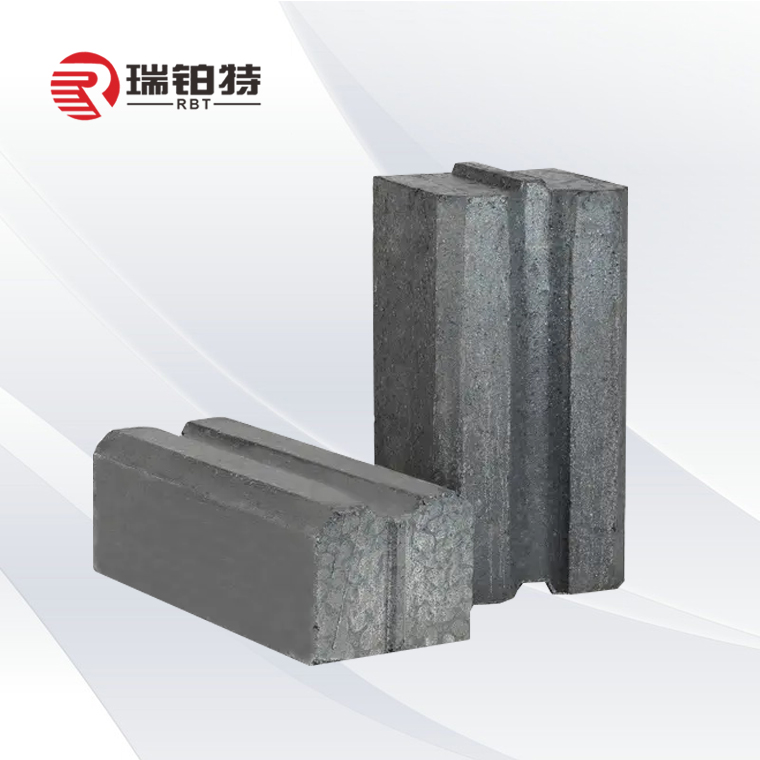

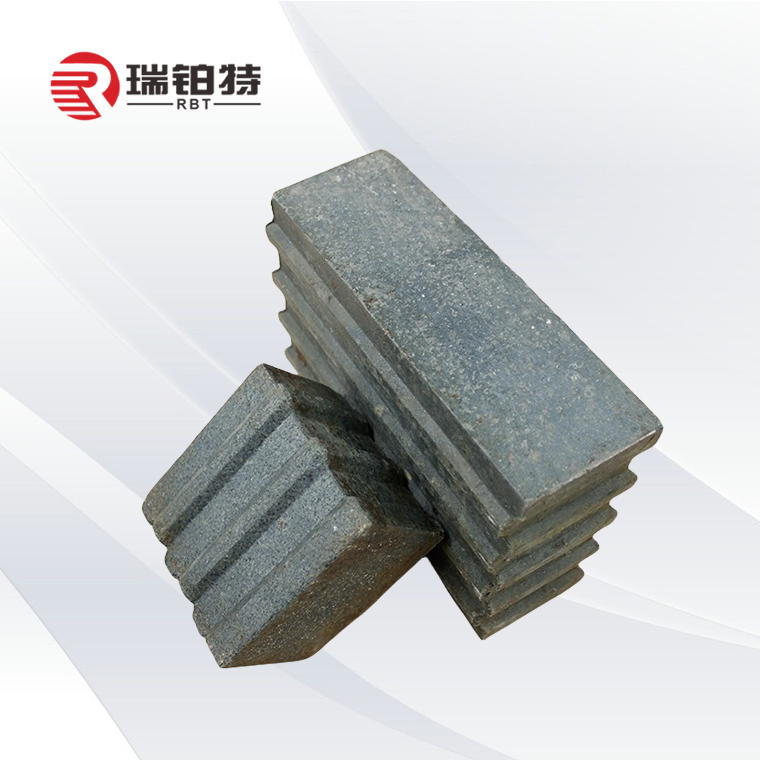

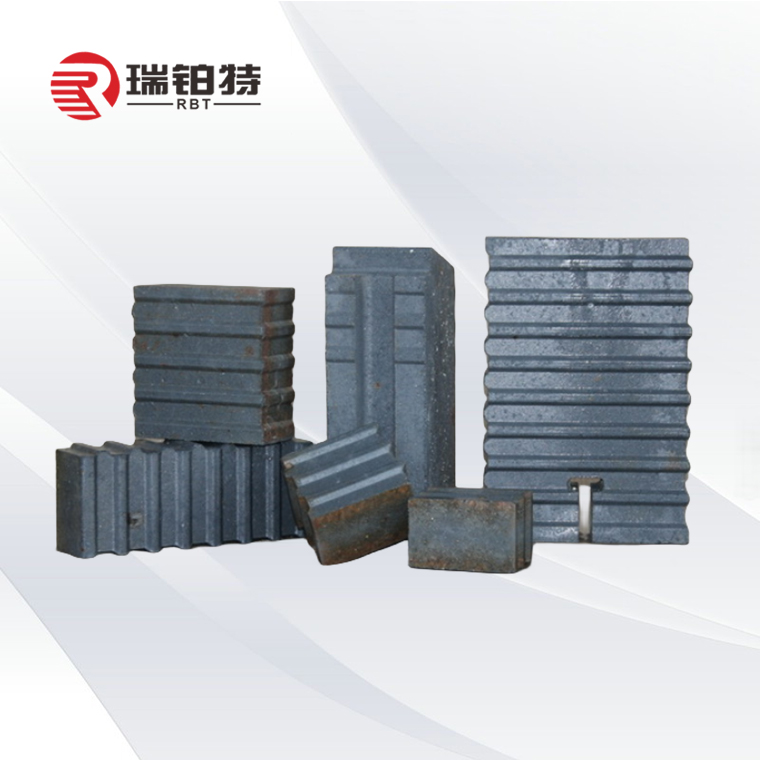

| Cov duab | Ncaj cib, tshwj xeeb-puab cib, cov neeg siv khoom xav tau! |

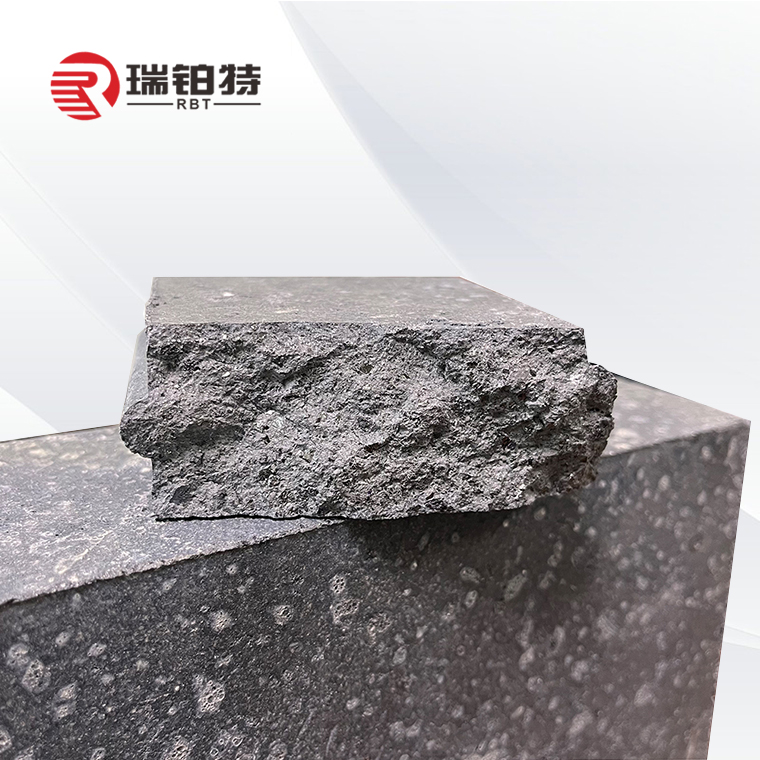

| Nta | 1. Zoo heev oxidation kuj 2. Thermal shock stability 3. Compact qauv 4. Siab kub ntim stability 5. Siab kub flexural zog |

Cov duab ntxaws

Txuj ci ci

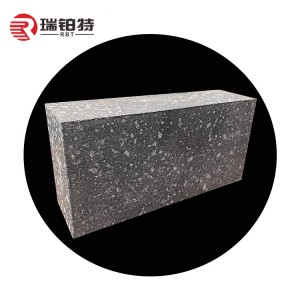

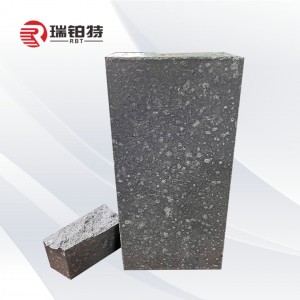

Cov cib zoo li

Cov cib zoo li

Cov cib zoo li

Txuj ci ci

Cov cib zoo li

Cov cib zoo li

Cov cib zoo li

Product Index

| INDEX | RBTSC |

| Refractoriness (℃) ≥ | 1750 |

| Qhov ntom ntom (g / cm3) ≥ | 2.60 Nws |

| Pom tseeb Porosity(%) ≤ | 10 |

| Txias Crushing Zog (MPa) ≥ | 80 |

| Thermal conductivity (W / mk) | 8-15 |

| Refractoriness Nyob rau hauv Load @ 0.2MPa (℃) ≥ | 1700 |

| SIC(%) ≥ | 85 |

| SiO2(%) ≥ | 10 |

Daim ntawv thov

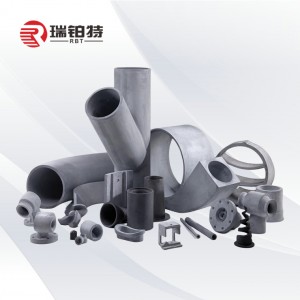

1. tuaj yeem siv rau hauv metallurgical steel drum linings, nozzles, plugs, blast furnace bottoms thiab bosses, water-cooled slide rails nyob rau hauv cov cua kub cua sov;

2. Non-ferrous hlau smelting stills, distillation ntauwd tais, sab phab ntsa ntawm electrolyzers, smelting hlau crucibles;

3. Silicic acid txee boards thiab flameproof cov ntaub ntawv rau ntsev kev lag luam kilns;

4. Lub tshuab hluav taws xob roj thiab roj thiab cov organic pov tseg combustion rauv hauv kev lag luam tshuaj;

5. Kiln rooj tog rau high-tech ceramics, aluminium electrolytic cell linings, molten aluminium conduits, thiab kiln rooj tog rau ceramic kilns, loj thiab nruab nrab blast furnaces qis lub cev, rauv duav thiab plab, aluminium refining rauv hauv ob sab phlu, zinc distillation tank hauv ob sab phlu. , lwm.

Blast Rauv

Rotary Kiln

Ceramic Kiln

Kev lag luam tshuaj

Pob & Warehouse

Cov lus nug nquag

Xav tau kev pab?Nco ntsoov mus saib peb lub rooj sab laj kev txhawb nqa rau cov lus teb rau koj cov lus nug!

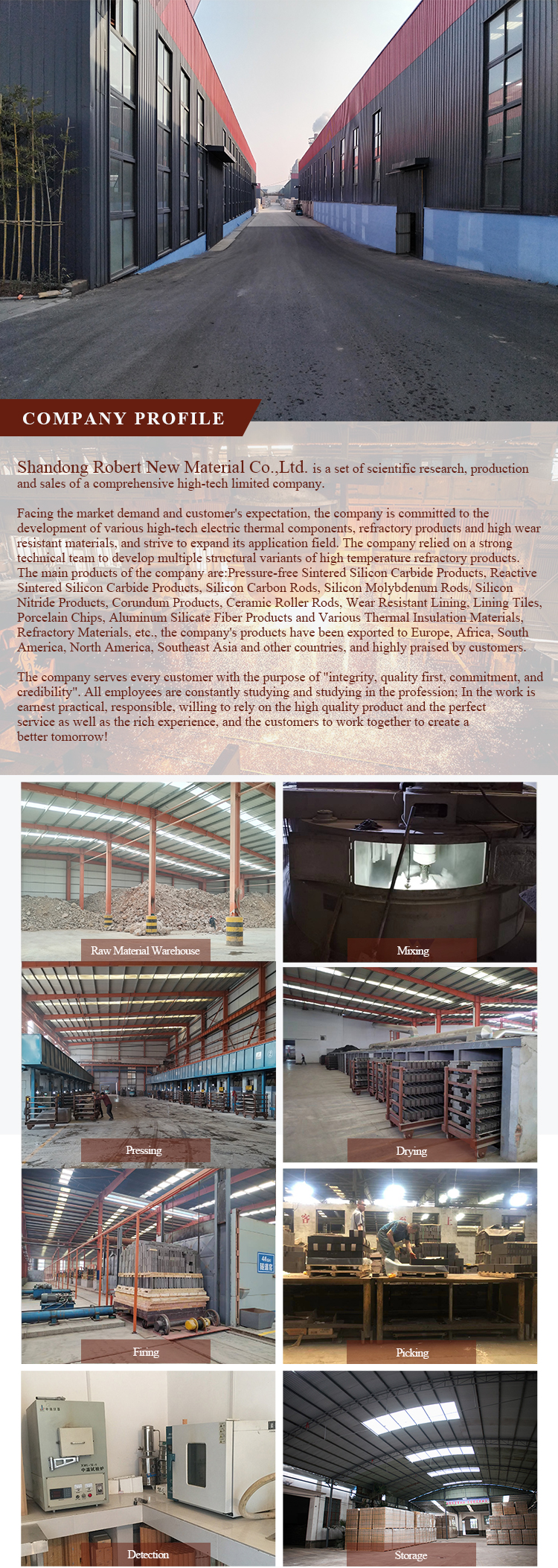

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov ntaub ntawv refractory rau ntau tshaj 30 xyoo.Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov zoo tshaj plaws ua ntej muag thiab kev pab cuam tom qab muag.

Rau txhua tus txheej txheem tsim khoom, RBT muaj kev ua tiav QC rau cov tshuaj muaj pes tsawg leeg thiab lub cev muaj zog.Thiab peb yuav kuaj cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom.Yog tias koj muaj cov cai tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws kom haum lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv.Tab sis peb cog lus tias yuav nkoj sai li sai tau nrog lav zoo.

Tau kawg, peb muab cov qauv dawb.

Yog lawm, tau kawg, txais tos tuaj xyuas RBT tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov ntaub ntawv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb zog thiab kev nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov khoom sib txawv thiab muab kev pabcuam ib-nres.