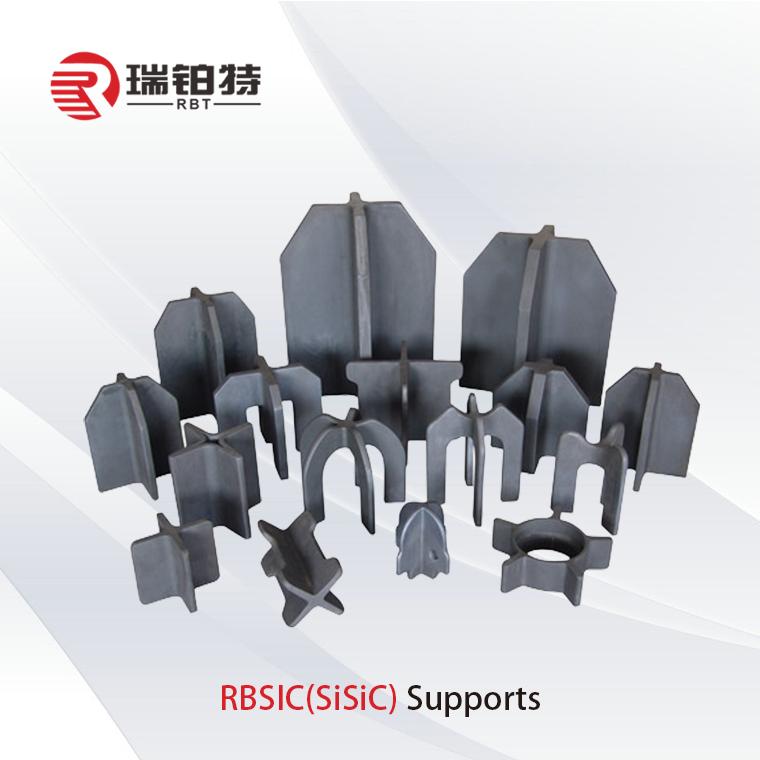

RBSiC (SiSiC) cov khoom

Cov ntaub ntawv khoom

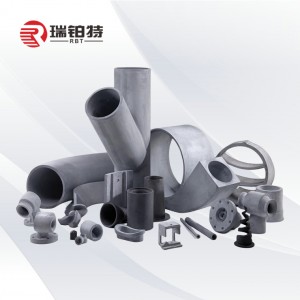

| KhoomLub npe | RBSIC (SiSiC) Cov Khoom (Reactive Sintering Silicon Carbide Khoom) |

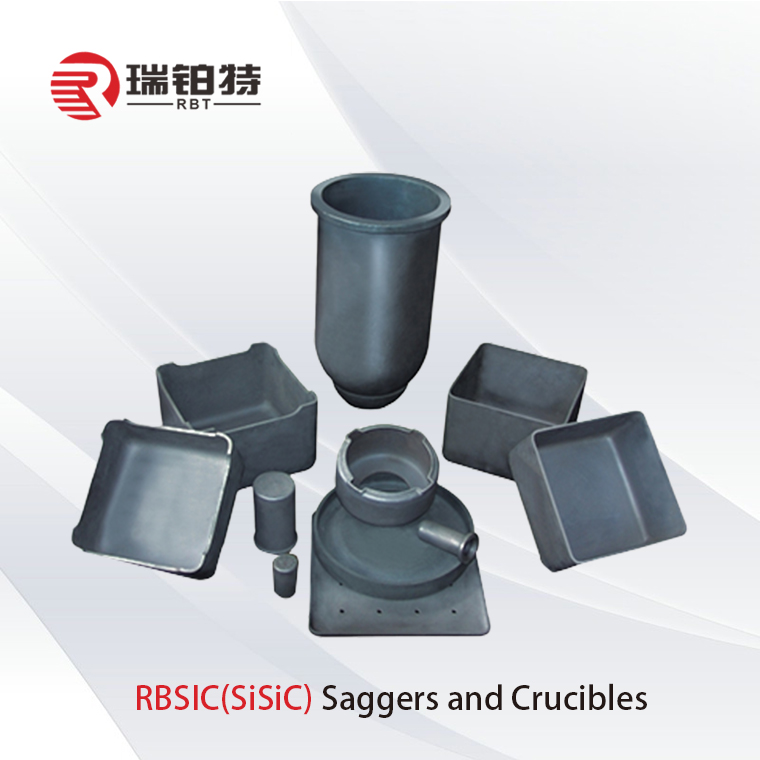

| Kev piav qhia | Siliconized SiC yog cov tshuaj silicon uas sib xyaw ua ke thiab nkag mus nrog cov khoom zoo ntawm SiC, carbon hmoov thiab cov khoom ntxiv hauv kev faib ua feem los tsim SiC thiab ua ke nrog SiC, ntau silicon puv qhov khoob kom tau txais cov ntaub ntawv ceramic heev. |

| Feature | Cov khoom siv ntawm siliconized silicon carbide muaj cov txheej txheem ntawm kev ua tau zoo tshaj plaws thiab cov yam ntxwv xws li lub zog siab, siab tawv, hnav tsis kam, siab kub siab siab, corrosion tsis kam, oxidation kuj thermal poob siab, siab thermal conductivity, qis coefficient ntawm thermal expansion, creep kuj nyob rau hauv kub kub thiab lwm yam. Ntau yam khoom tuaj yeem ua los ntawm nws xws li kab teeb, chais, cua txias kav, thermal ob leeg tiv thaiv raj, ntsuas kub ntsuas tub, sealing qhov chaw, thiab tshwj xeeb zoo li tus. |

Product Index

| Yam khoom | Chav tsev | Cov ntaub ntawv |

| Max kub ntawm daim ntawv thov | ℃ | ≤1380 |

| Qhov ntom | g/cm3 | 3.02 Nws |

| Qhib Porosity | % | ≤0.1 |

| Khoov zog | Mpa | 250 (20 ℃);280 (1200 ℃) |

| Modulus ntawm Elastictiy | Gpa | 330 (20 ℃);300 (1200 ℃) |

| Thermal conductivity | W/mk | 45 (1200 ℃) |

| Thermal Expansion Coefficient | K-1 * 10-6 | 4.5 |

| Moh's Hardness | | 9.15 Nws |

| Acid Alkaline-pov thawj | | Zoo heev |

Cov duab ntxaws

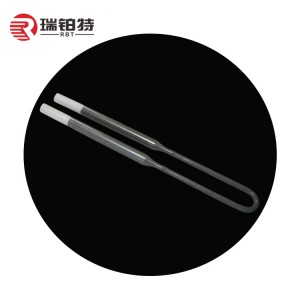

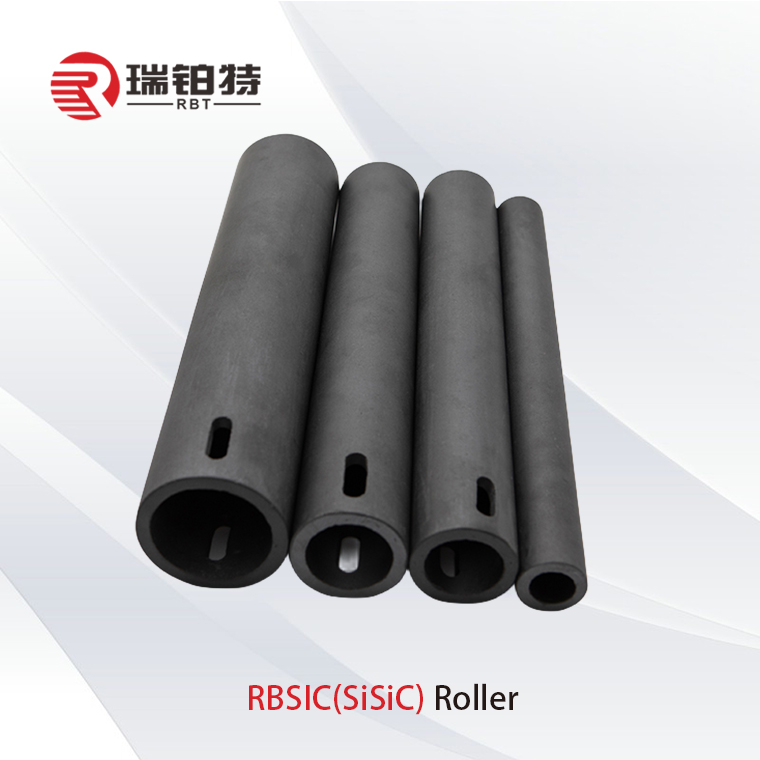

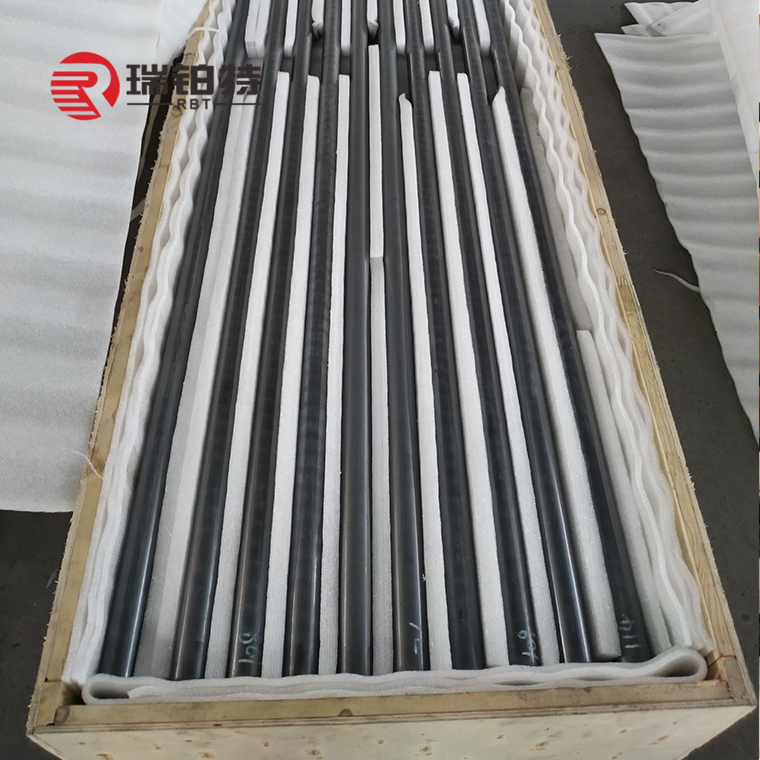

Feature:Cov tshuaj tiv thaiv zoo heev ntawm silicon carbide yob pas nrig ua rau nws tuaj yeem ua haujlwm tau ntev hauv qhov chaw muaj zog corrosive ib puag ncig ntawm lithium hluav taws xob kiln, thiab muaj lub neej ntev dua.

| Bearing Peev Xwm ntawm RBSic (SiSiC) Rollers | |||

| LojntawmTshooj(mm) | Phab ntsaThickness(mm) | Nco ntsoovThauj khoom (kg.m/L) | UniformlyMuab faibThauj khoom (kg.m/L) |

| 30 | 5 | 43 | 86 |

| 35 | 5 | 63 | 126 |

| 35 | 6 | 70 | 140 |

| 38 | 5 | 77 | 154 |

| 40 | 6 | 97 | 197 |

| 45 | 6 | 130 | 260 |

| 50 | 6 | 167 | 334 ib |

| 60 | 7 | 283 | 566 ib |

| 70 | 7 | 405 | 810 |

Daim ntawv thov:Ua luam dej kiln, qhov kiln, cov menyuam kiln, thiab lwm yam kev lag luam kiln bearing qauv thiab cov kiln tsheb bearing khoom.

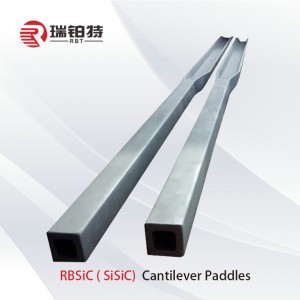

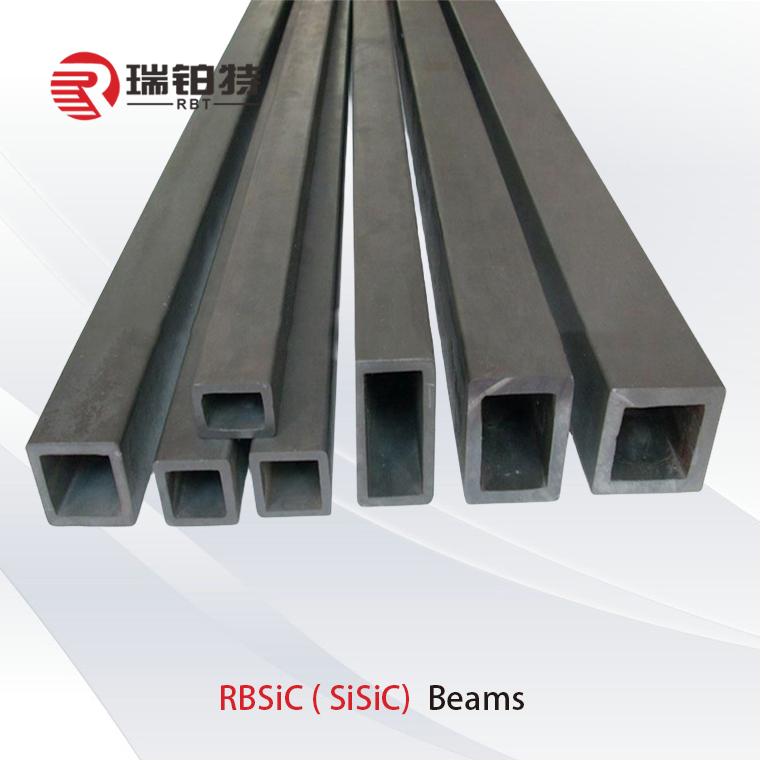

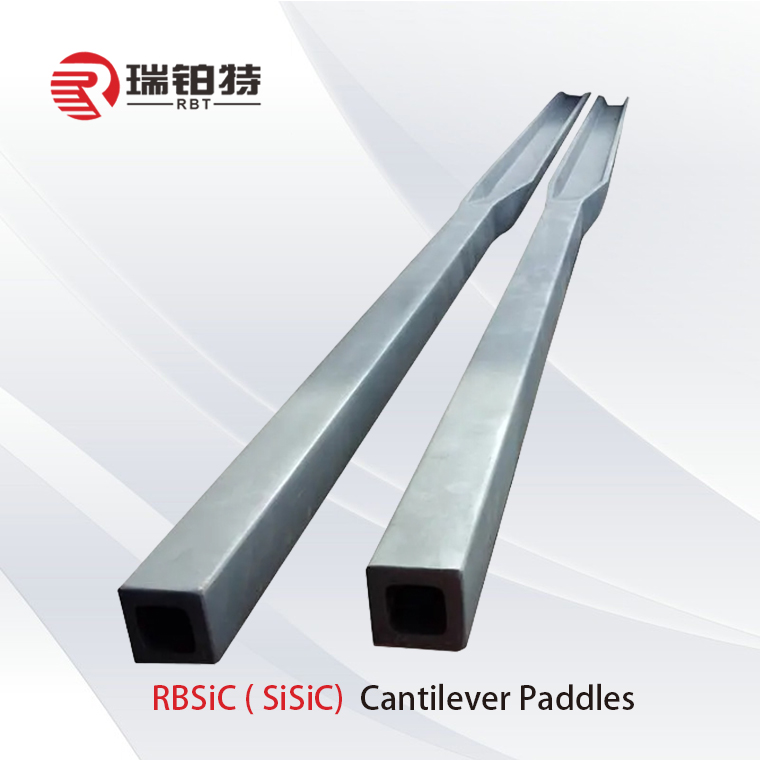

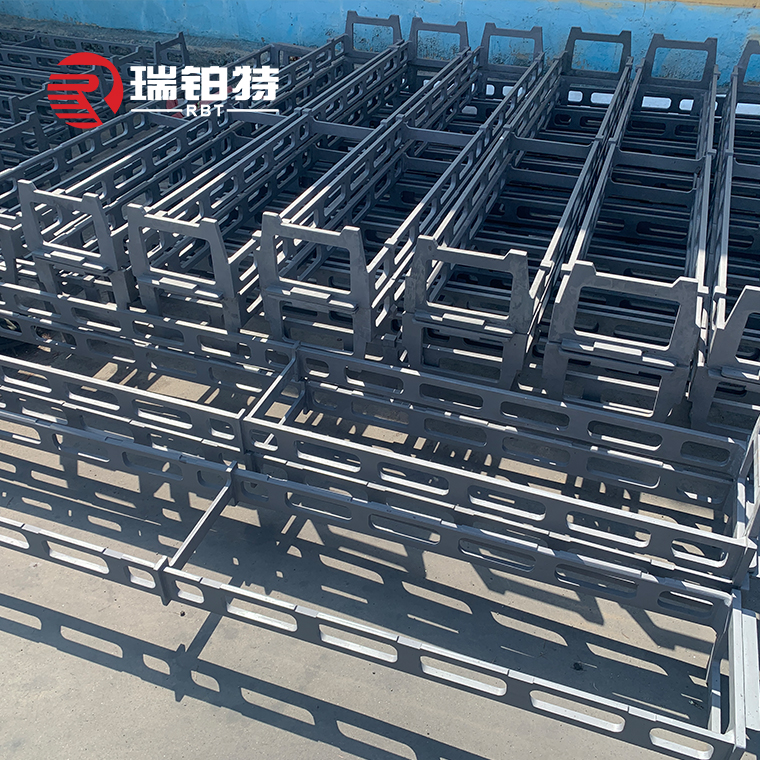

Feature:Silicon carbide square beam muaj qhov zoo ntawm qhov loj qhov kub thiab txias muaj peev xwm, zoo thermal conductivity, kub creep tsis kam thiab lub zog txuag.lt yog qhov zoo tagnrho kiln rau lithium hluav taws xob cov menyuam qws kiln, hluav taws xob ceramic hmoov, khoom siv huv si, txhua hnub ceramics, hluav taws xob porcelain, cov ntaub ntawv refractory, ua npuas ncauj ceramics, thiab lwm yam lag luam.

| Bearing Capacity ntawm RBSic (SiSiC) Beams | ||||||

| Qhov loj ntawm Tshooj (mm) | Phab ntsa Thickness (mm) | Concentrated Loading (kg.m/L) | Uniformly Distributed Loading (kg.m/L) | |||

| B Sab | H Sab | W Sab | H Sab | W Sab | H Sab | |

| 30 | 30 | 5 | 74 | 74 | 147 | 147 |

| 30 | 40 | 5 | 117 | 95 | 235 | 190 |

| 40 | 40 | 6 | 149 | 149 | 298 | 298 |

| 50 | 50 | 6 | 283 | 283 | 567 ib | 567 ib |

| 50 | 60 | 6 | 374 ib | 331 | 748 ib | 662 ib |

| 50 | 70 | 6 | 473 ib | 379 ib | 946 ib | 757 ib |

| 60 | 60 | 7 | 481 ib | 481 ib | 962 ib | 962 ib |

| 80 | 80 | 7 | 935 ua | 935 ua | Xyoo 1869 | Xyoo 1869 |

| 100 | 100 | 8 | 1708 ib | 1708 ib | ib 3416 | ib 3416 |

| 110 | 110 | 10 | 2498 ib | 2498 ib | ib 4997 | ib 4997 |

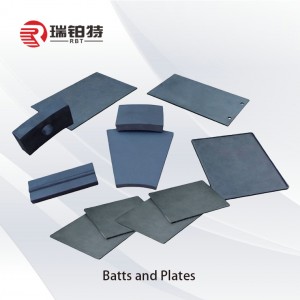

Burner Casing

Radiation Tube

Liners

Txhawb nqa

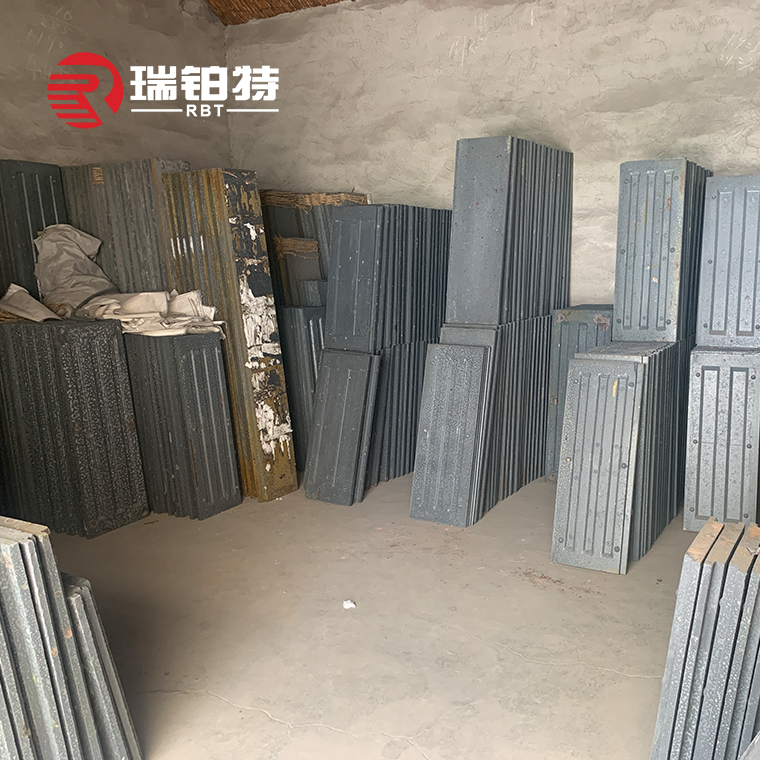

Pob & Warehouse

Cov lus nug nquag

Xav tau kev pab?Nco ntsoov mus saib peb lub rooj sab laj kev txhawb nqa rau cov lus teb rau koj cov lus nug!

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov ntaub ntawv refractory rau ntau tshaj 30 xyoo.Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov zoo tshaj plaws ua ntej muag thiab kev pab cuam tom qab muag.

Rau txhua tus txheej txheem tsim khoom, RBT muaj kev ua tiav QC rau cov tshuaj muaj pes tsawg leeg thiab lub cev muaj zog.Thiab peb yuav kuaj cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom.Yog tias koj muaj cov cai tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws kom haum lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv.Tab sis peb cog lus tias yuav nkoj sai li sai tau nrog lav zoo.

Tau kawg, peb muab cov qauv dawb.

Yog lawm, tau kawg, txais tos tuaj xyuas RBT tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov ntaub ntawv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb zog thiab kev nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov khoom sib txawv thiab muab kev pabcuam ib-nres.