Qhov zoo ntawm magnesia carbon bricks yog:tsis kam rau slag yaig thiab zoo thermal shock kuj.Yav dhau los, qhov tsis zoo ntawm MgO-Cr2O3 cib thiab dolomite cib yog tias lawv nqus cov slag Cheebtsam, ua rau cov txheej txheem spalling, ua rau muaj kev puas tsuaj ntxov ntxov.Los ntawm kev ntxiv graphite, magnesia carbon bricks tshem tawm qhov tsis txaus no.Nws cov yam ntxwv yog tias cov slag tsuas yog nkag mus rau hauv qhov chaw ua haujlwm, yog li cov txheej txheem tshuaj tiv thaiv Confined rau qhov chaw ua haujlwm, cov qauv muaj tsawg dua tev thiab ua haujlwm ntev.

Tam sim no, ntxiv rau cov tsoos asphalt thiab resin-bonded magnesia carbon bricks (xws li raug rho tawm roj-impregnated magnesia cib),cov magnesia carbon cib muag hauv khw suav nrog:

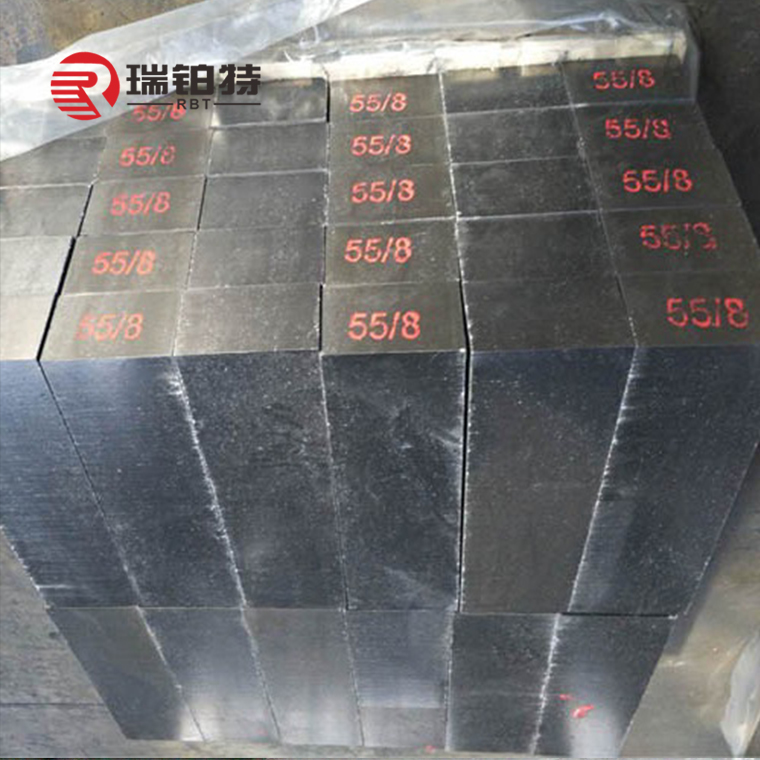

(1) Magnesia carbon cib ua los ntawm magnesia muaj 96% ~ 97% MgO thiab graphite 94% ~ 95% C;

(2) Magnesia carbon cib ua los ntawm magnesia muaj 97.5% ~ 98.5% MgO thiab graphite 96% ~ 97% C;

(3) Magnesia carbon cib ua los ntawm magnesia muaj 98.5% ~ 99% MgO thiab 98% ~ C graphite.

Raws li cov ntsiab lus carbon, magnesia carbon bricks tau muab faib ua:

(I) Hluav taws xob roj-impregnated magnesia cib (cov ntsiab lus carbon tsawg dua 2%);

(2) Carbon bonded magnesia bricks (cov ntsiab lus carbon tsawg dua 7%);

(3) Synthetic resin bonded magnesia carbon cib (cov ntsiab lus carbon yog 8% ~ 20%, mus txog 25% hauv ob peb kis).Antioxidants feem ntau ntxiv rau asphalt / resin bonded magnesia carbon cib (cov ntsiab lus carbon yog 8% mus rau 20%).

Magnesia carbon bricks yog tsim los ntawm kev sib txuas ntawm high-purity MgO xuab zeb nrog scaly graphite, carbon dub, thiab lwm yam. Cov txheej txheem tsim muaj xws li cov txheej txheem hauv qab no: raw khoom crushing, tshuaj ntsuam, grading, sib tov raws li cov khoom tsim qauv thiab cov khoom tsim kev ua tau zoo, raws li. Kev sib xyaw ua ke Qhov kub ntawm tus neeg sawv cev yog tsa kom ze rau 100 ~ 200 ℃, thiab nws yog kneaded ua ke nrog cov ntawv khi kom tau txais qhov hu ua MgO-C av nkos (ntsuab lub cev sib xyaw).MgO-C av nkos siv cov khoom siv hluavtaws (feem ntau yog phenolic resin) yog molded hauv lub xeev txias;MgO-C cov av nkos ua ke nrog asphalt (rhuab mus rau lub xeev cov kua dej) yog molded nyob rau hauv ib tug kub lub xeev (ntawm txog 100 ° C) tsim.Raws li batch loj thiab kev ua tau zoo ntawm MgO-C cov khoom, lub tshuab nqus tsev vibration khoom, compression molding khoom, extruders, isostatic presses, kub presses, cua sov khoom, thiab ramming khoom siv tau los ua MgO-C av nkos cov ntaub ntawv.mus rau lub hom phiaj zoo tagnrho.Cov tsim MgO-C lub cev tau muab tso rau hauv ib lub qhov cub ntawm 700 ~ 1200 ° C rau kev kho cua sov kom hloov cov neeg ua haujlwm khi rau hauv cov pa roj carbon (cov txheej txheem no hu ua carbonization).Txhawm rau ua kom qhov ntom ntom ntawm magnesia carbon bricks thiab ntxiv dag zog rau kev sib txuas, cov khoom ua kom zoo ib yam li cov binders tuaj yeem siv los impregnate cov cib.

Niaj hnub no, hluavtaws cob (tshwj xeeb tshaj yog phenolic resin) feem ntau yog siv los ua tus neeg sawv cev ntawm magnesia carbon cib.Kev siv cov khoom siv hluavtaws sib txuas nrog magnesia carbon cib muaj cov hauv qab no zoo:

(1) Ib puag ncig zoo tso cai rau kev ua thiab tsim cov khoom no;

(2) Cov txheej txheem ntawm kev tsim cov khoom nyob rau hauv kev sib xyaw txias txias txuag lub zog;

(3) Cov khoom tuaj yeem ua tiav raws li qhov tsis yog-kho;

(4) Piv nrog tar asphalt binder, tsis muaj theem yas;

(5) Cov ntsiab lus carbon ntxiv (ntau dua graphite lossis bituminous thee) tuaj yeem txhim kho hnav tsis kam thiab slag kuj.

Post lub sij hawm: Feb-23-2024