Dub Silicon Carbide

Cov ntaub ntawv khoom

Dub Silicon Carbide (SiC)yog ib qho nyuaj heev (Mohs 9.1 / 2550 Knoop) txiv neej ua cov ntxhia uas muaj cov thermal conductivity thiab siab zog ntawm qhov kub siab (ntawm 1000 ° C, SiC yog 7.5 npaug zog dua Al203). SiC muaj qhov hloov pauv ntawm elasticity ntawm 410 GPa, tsis muaj qhov txo qis ntawm lub zog mus txog 1600 ° C, thiab nws tsis yaj ntawm cov kev kub ntxhov ib txwm tab sis hloov pauv ntawm 2600 ° C.

Daim ntawv thov:

Dub silicon carbide blocksfeem ntau yog siv rau hauv daim ntawv thov uas yuav tsum tau txiav, ua los yog sib tsoo, xws li npaj sib tsoo log, txiav discs, thiab lwm yam.

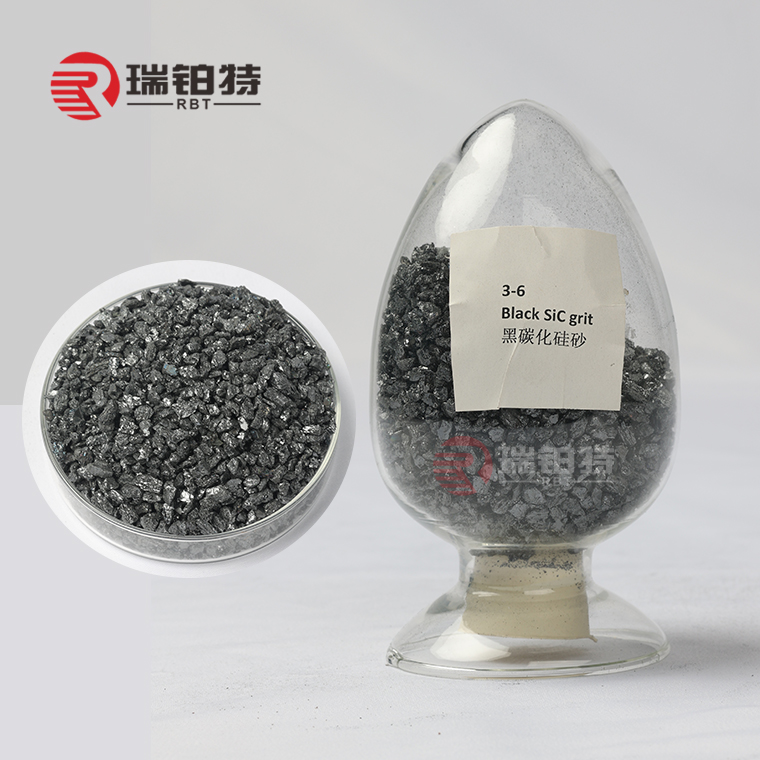

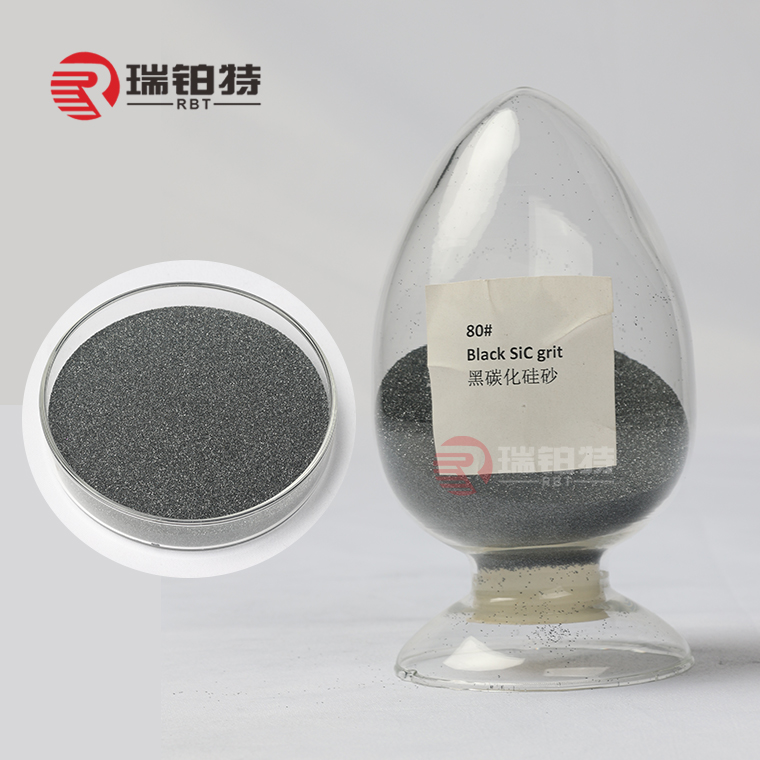

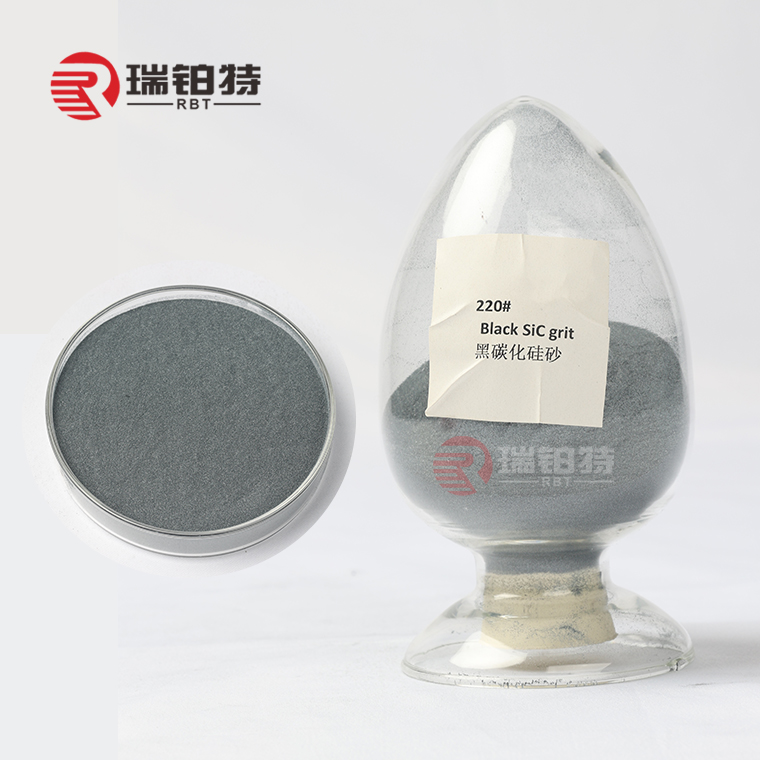

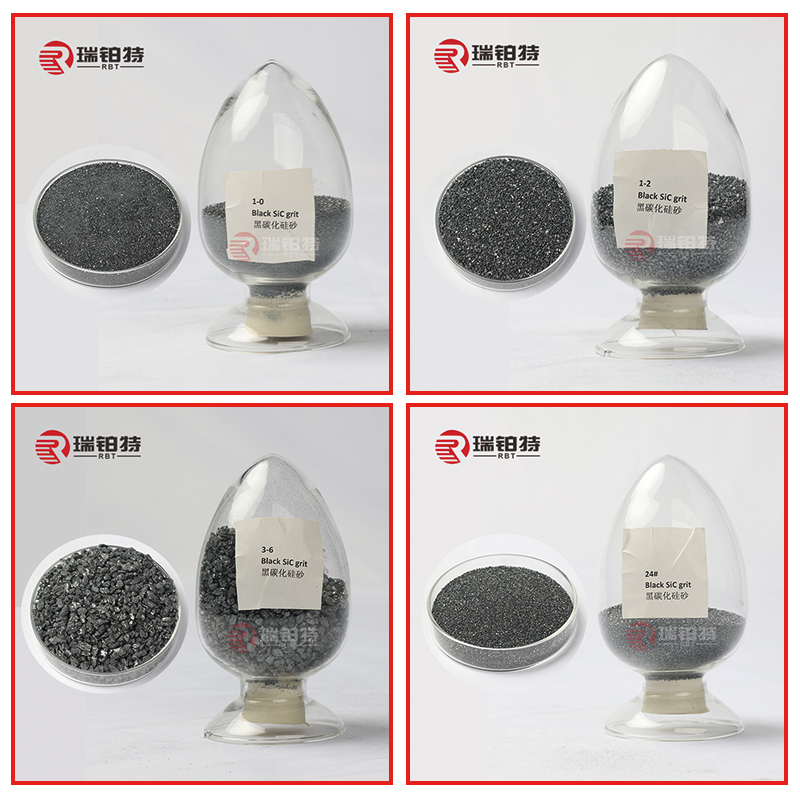

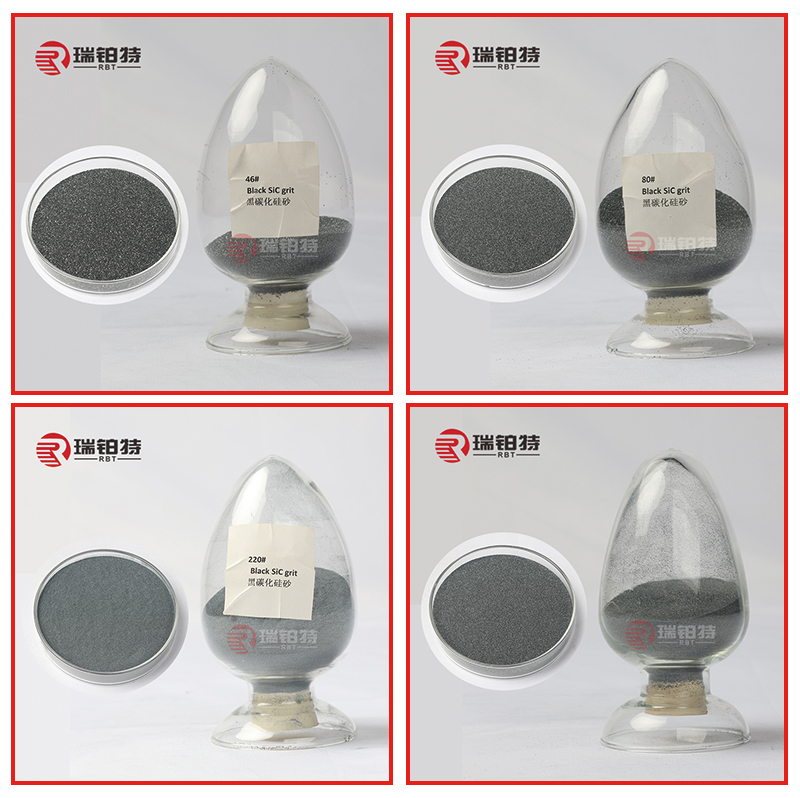

Qhov loj ntawmdub silicon carbide gritfeem ntau yog li ntawm ob peb millimeters mus rau kaum microns. Feem ntau siv hauv sandblasting, polishing, kho deg thiab lwm yam kev siv los muab cov khoom sib xws thiab huv si.

Qhov particle loj ntawmdub silicon carbide hmoovfeem ntau yog nyob rau hauv nanometer rau micron theem. Cov khoom siv hmoov yog feem ntau siv rau hauv cov khoom siv ntxiv, coatings, fillers thiab lwm yam kev siv.

Cov duab ntxaws

Grit Size Comparison Chart

| Grit No. | Tuam Tshoj GB2477-83 | Nyiv JISR 6001-87 | USA ANSI (76) | 欧洲磨料协 FEPA (84) | Daim ntawv pov thawj ISO (86) |

| 4 | 5600-4750 Ib |

| 5600-4750 Ib | 5600-4750 Ib | 5600-4750 Ib |

| 5 | 4750-4000 Nws |

| 4750-4000 Nws | 4750-4000 Nws | 4750-4000 Nws |

| 6 | 4000-3350 |

| 4000-3350 | 4000-3350 | 4000-3350 |

| 7 | 3350-2800 Nws |

| 3350-2800 Nws | 3350-2800 Nws | 3350-2800 Nws |

| 8 | 2800-2360 Nws | 2800-2360 Nws | 2800-2360 Nws | 2800-2360 Nws | 2800-2360 Nws |

| 10 | 2360-2000 Nws | 2360-2000 Nws | 2360-2000 Nws | 2360-2000 Nws | 2360-2000 Nws |

| 12 | 2000-1700 Nws | 2000-1700 Nws | 2000-1700 Nws | 2000-1700 Nws | 2000-1700 Nws |

| 14 | 1700-1400 Nws | 1700-1400 Nws | 1700-1400 Nws | 1700-1400 Nws | 1700-1400 Nws |

| 16 | 1400-1180 Nws | 1400-1180 Nws | 1400-1180 Nws | 1400-1180 Nws | 1400-1180 Nws |

| 20 | 1180-1000 Nws | 1180-1100 Nws | 1180-1000 Nws | 1180-1000 Nws | 1180-1000 Nws |

| 22 | 1000-850 | - | - | 1000-850 | 1000-850 |

| 24 | 850-710 : kuv | 850-710 : kuv | 850-710 : kuv | 850-710 : kuv | 850-710 : kuv |

| 30 | 710-600 Nws | 710-600 Nws | 710-600 Nws | 710-600 Nws | 710-600 Nws |

| 36 | 600-500 | 600-500 | 600-500 | 600-500 | 600-500 |

| 40 | 500-425 : kuv | - | - | 500-425 : kuv | 500-425 : kuv |

| 46 | 425-355 : kuv | 425-355 : kuv | 425-355 : kuv | 425-355 : kuv | 425-355 : kuv |

| 54 | 355-300 : kuv | 355-300 : kuv | 355-297 : kuv | 355-300 : kuv | 355-300 : kuv |

| 60 | 300-250 | 300-250 | 297-250 : kuv | 300-250 | 300-250 |

| 70 | 250-212 : kuv | 250-212 : kuv | 250-212 : kuv | 250-212 : kuv | 250-212 : kuv |

| 80 | 212-180 : kuv | 212-180 : kuv | 212-180 : kuv | 212-180 : kuv | 212-180 : kuv |

| 90 | 180-150 : kuv | 180-150 : kuv | 180-150 : kuv | 180-150 : kuv | 180-150 : kuv |

| 100 | 150-125 : kuv | 150-125 : kuv | 150-125 : kuv | 150-125 : kuv | 150-125 : kuv |

| 120 | 125-106 : kuv | 125-106 : kuv | 125-106 : kuv | 125-106 : kuv | 125-106 : kuv |

| 150 | 106-75 : kuv | 106-75 : kuv | 106-75 : kuv | 106-75 : kuv | 106-75 : kuv |

| 180 | 90-63 : kuv | 90-63 : kuv | 90-63 : kuv | 90-63 : kuv | 90-63 : kuv |

| 220 | 75-53 : kuv | 75-53 : kuv | 75-53 : kuv | 75-53 : kuv | 75-53 : kuv |

| 240 | 75-53 : kuv | - | 75-53 : kuv | - |

Product Index

| Grit Loj | Chemical Composition% (los ntawm qhov hnyav) | ||

| SIC | F·C | Fe2O 3 | |

| 12#-90# | ≥98.50 | ≤ 0.20 | ≤ 0.60 |

| 100 # - 180 # | ≥98.00 Nws | ≤ 0.30 | ≤ 0.80 |

| 220 # - 240 # | ≥97.00 Nws | ≤ 0.30 | ≤ 1.20 |

| W63-W20 | ≥96.00 Nws | ≤ 0.40 | ≤1.50 |

| W14-W5 | ≥93.00 Nws | ≤ 0.40 | ≤ 1.70 |

Daim ntawv thov

Abrasives thiab sib tsoo cov cuab yeej:Vim nws cov hardness siab thiab tej yam toughness, dub silicon carbide xuab zeb yog dav siv nyob rau hauv kev sib tsoo thiab polishing ntawm optical iav, cemented carbide, titanium alloy, bearing steel, thiab sharpening ntawm high-ceev steel cov cuab yeej. Nws kuj tseem tsim nyog rau kev txiav thiab sib tsoo cov ntaub ntawv uas tsis tshua muaj zog tensile, xws li slicing ntawm ib leeg siv lead ua silicon thiab polycrystalline silicon rods, sib tsoo ntawm ib leeg siv lead ua silicon wafers, thiab lwm yam.

Cov khoom siv refractory:Hauv kev lag luam metallurgical, cov xuab zeb dub silicon carbide feem ntau yog siv los ua cov hauv ob sab phlu, hauv qab thiab thaj ua rau lub qhov cub kub kub kom ntseeg tau tias cov khoom siv hlau ua haujlwm ib txwm muaj. Nws tseem yog tsim los rau hauv cov ntaub ntawv refractory, xws li cov khoom siv hluav taws xob kub kub thiab kev txhawb nqa, uas tiv taus thermal shock, me me, lub teeb hauv qhov hnyav thiab siab zog, thiab muaj kev txuag hluav taws xob zoo. cov

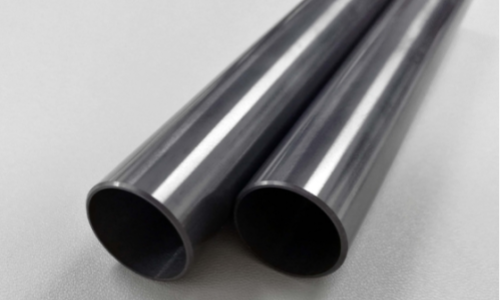

Kev Siv Tshuaj:Hauv kev lag luam chemical, dub silicon carbide xuab zeb yog siv los tsim cov khoom siv tshuaj tiv thaiv corrosion-resistant, cov kav dej thiab cov li qub kom ntseeg tau tias kev ua haujlwm zoo ntawm cov khoom siv nyob rau hauv corrosive media thiab kub kub. Tsis tas li ntawd, nws tseem tuaj yeem siv los ua cov khoom siv purifier rau smelting steel, uas yog, deoxidizer rau steelmaking thiab cam khwb cia hlau qauv txhim kho. ua

Electronics Kev Lag Luam:Hauv kev lag luam hluav taws xob, cov xuab zeb dub silicon carbide yog siv los tsim cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob, xws li cov khoom siv hluav taws xob muaj zog, cov khoom siv hluav taws xob sib txuas, thiab lwm yam. ua

Lwm yam kev siv:Dub silicon carbide xuab zeb kuj tseem siv los ua cov khoom siv hluav taws xob, hluav taws xob cua sov, cov khoom siv hluav taws xob kub kub, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, thiab lwm yam.

Pob & Warehouse

| Pob | 25 KG Tas | 1000KG Hnab |

| Ntau | 24-25 Tuj | 24 Tons |

Tuam txhab Profile

Shandong Robert Tshiab Khoom Co., Ltd.yog nyob rau hauv Zibo City, Shandong xeev, Suav teb, uas yog ib tug refractory khoom tsim los puag. Peb yog ib lub tuam txhab niaj hnub uas koom nrog kev tshawb fawb thiab kev tsim kho, kev tsim khoom, muag, kiln tsim thiab kev tsim kho, thev naus laus zis, thiab xa tawm cov ntaub ntawv refractory. Peb muaj cov cuab yeej ua tiav, cov thev naus laus zis siab heev, muaj zog technical, cov khoom zoo heev, thiab lub koob npe zoo. Peb lub Hoobkas npog ntau tshaj 200 daim av thiab cov khoom tsim tawm txhua xyoo ntawm cov khoom siv refractory yog kwv yees li 30000 tons thiab cov ntaub ntawv tsis zoo yog 12000 tons.

Peb cov khoom tseem ceeb ntawm cov ntaub ntawv refractory muaj xws li:alkaline refractory khoom; aluminium silicon refractory cov ntaub ntawv; unshaped refractory khoom; rwb thaiv tsev thermal refractory cov ntaub ntawv; cov ntaub ntawv tshwj xeeb refractory; functional refractory cov ntaub ntawv rau nruam casting tshuab.

Cov lus nug nquag

Xav tau kev pab? Nco ntsoov mus saib peb lub rooj sab laj kev txhawb nqa rau cov lus teb rau koj cov lus nug!

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov ntaub ntawv refractory rau ntau tshaj 30 xyoo. Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov zoo tshaj plaws ua ntej muag thiab kev pab cuam tom qab muag.

Rau txhua tus txheej txheem tsim khoom, RBT muaj kev ua tiav QC rau cov tshuaj muaj pes tsawg leeg thiab lub cev muaj zog. Thiab peb yuav kuaj cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom. Yog tias koj muaj cov cai tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws kom haum lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv. Tab sis peb cog lus tias yuav nkoj sai li sai tau nrog lav zoo.

Tau kawg, peb muab cov qauv dawb.

Yog lawm, tau kawg, txais tos tuaj xyuas RBT tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov ntaub ntawv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb zog thiab kev nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov khoom sib txawv thiab muab kev pabcuam ib-nres.