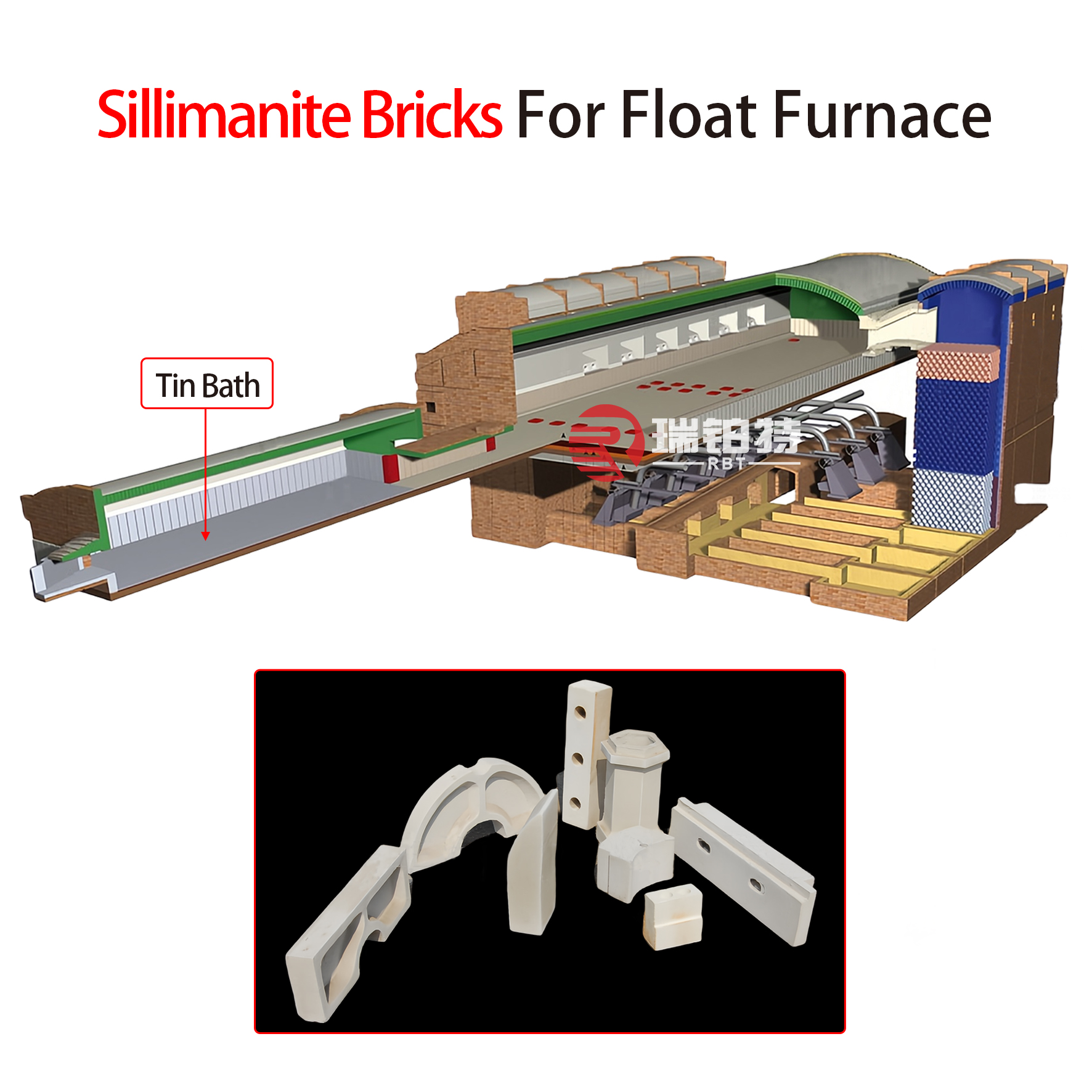

Piv txwv li, siv cov iav ntab ua piv txwv, peb yam khoom siv cua sov tseem ceeb hauv kev tsim iav suav nrog lub cub tawg iav ntab, lub dab dej iav ntab thiab lub cub tawg iav annealing. Hauv cov txheej txheem ntawm kev tsim iav, lub cub tawg iav yog lub luag haujlwm rau kev yaj cov khoom siv ua kua iav thiab ua kom meej, homogenizing thiab txias rau qhov kub uas xav tau rau kev pwm. Lub dab dej tin yog cov khoom siv tseem ceeb rau kev pwm iav. Cov kua iav nrog qhov kub ntawm 1050 ~ 1100 ℃ ntws los ntawm txoj kev ntws mus rau qhov chaw kua tin hauv lub dab dej tin. Cov kua iav raug flattened thiab polished rau ntawm qhov chaw ntawm lub dab dej tin, thiab raug tswj los ntawm kev rub tshuab, cov neeg tiv thaiv sab thiab cov tshuab kos sab los tsim ib daim kab xev iav ntawm qhov dav thiab tuab uas xav tau. Thiab nws tawm hauv lub dab dej tin thaum nws maj mam txias txog 600 ℃ thaum lub sijhawm ua ntej. Lub luag haujlwm ntawm lub cub tawg annealing yog tshem tawm cov kev ntxhov siab seem thiab qhov tsis sib xws ntawm cov iav ntab, thiab kom ruaj khov cov qauv sab hauv ntawm lub iav. Daim kab xev iav txuas ntxiv nrog qhov kub ntawm kwv yees li 600 ℃ los ntawm lub dab dej tin nkag mus rau hauv lub cub tawg annealing los ntawm lub rooj hloov pauv. Tag nrho peb yam khoom siv cua sov tseem ceeb no xav tau cov khoom siv refractory. Txhawm rau kom ntseeg tau tias lub cub tawg iav ua haujlwm zoo thiab ruaj khov, nws yeej tsis tuaj yeem sib cais los ntawm kev txhawb nqa ntawm ntau yam khoom siv refractory. Cov hauv qab no yog 9 hom khoom siv refractory feem ntau siv hauv cov cub tawg iav thiab lawv cov yam ntxwv:

Silica cib rau cov qhov cub iav:

Cov khoom xyaw tseem ceeb: silicon dioxide (SiO2), cov ntsiab lus yuav tsum siab tshaj 94%. Kev kub ua haujlwm: qhov kub ua haujlwm siab tshaj plaws yog 1600 ~ 1650 ℃. Nta: zoo tiv taus acidic slag erosion, tab sis tsis zoo tiv taus alkaline ya khoom erosion. Feem ntau siv rau masonry ntawm cov arches loj, phab ntsa hauv siab thiab cov cub tawg me me.

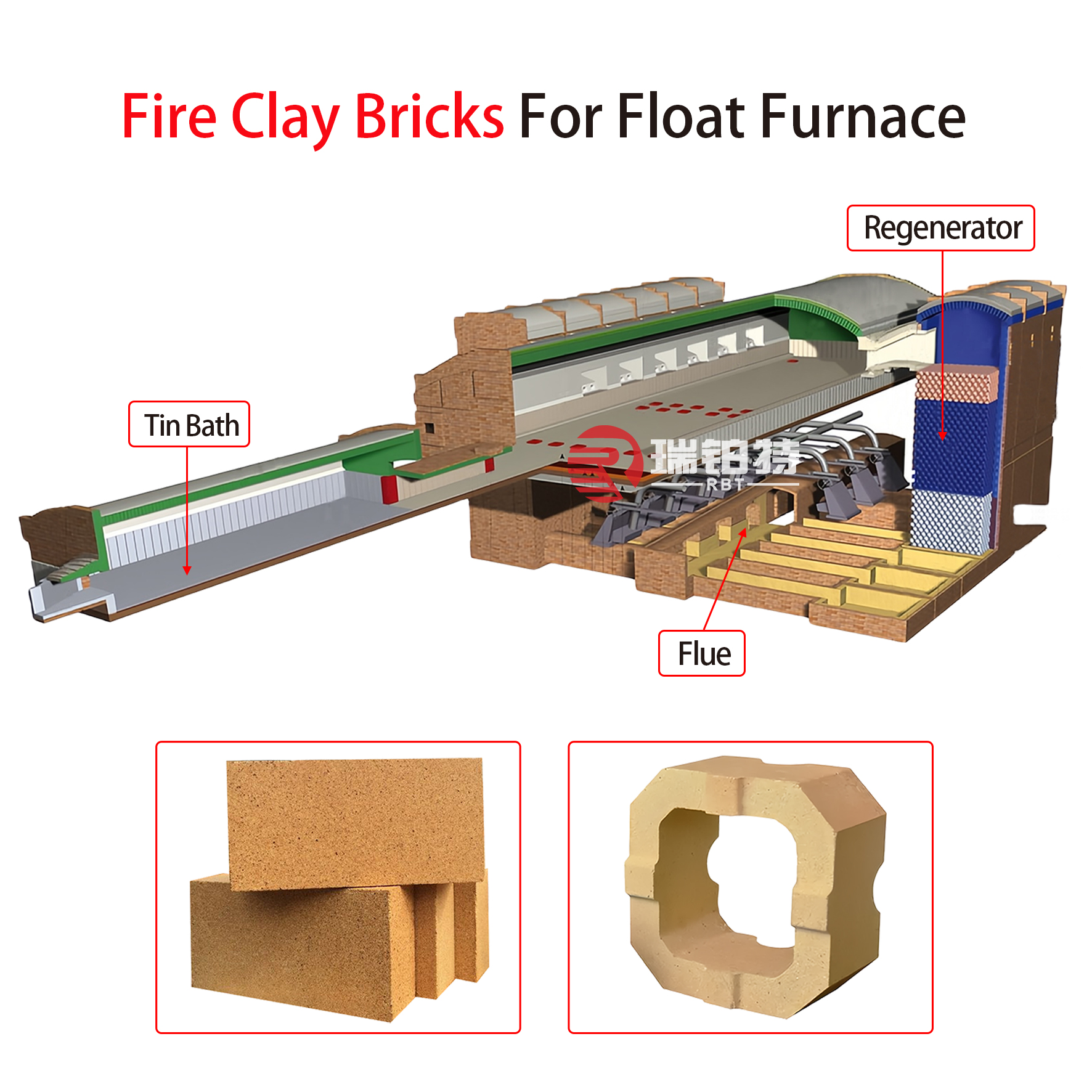

Cov cib av nplaum hluav taws rau cov qhov cub iav:

Cov khoom xyaw tseem ceeb: Al2O3 thiab SiO2, Al2O3 cov ntsiab lus yog nyob nruab nrab ntawm 30% ~ 45%, SiO2 yog nyob nruab nrab ntawm 51% ~ 66%. Qhov kub ua haujlwm: qhov kub ua haujlwm siab tshaj plaws yog 1350 ~ 1500 ℃. Nta: Nws yog cov khoom siv refractory tsis muaj zog nrog kev refractoriness zoo, thermal stability thiab thermal conductivity qis. Feem ntau siv rau masonry ntawm hauv qab ntawm lub pas dej ua ke, phab ntsa pas dej ua ke ntawm qhov chaw ua haujlwm thiab txoj kev hla, phab ntsa, arch, qis checker cib thiab flue ntawm chav cia cua sov.

Cov cib alumina siab rau cov qhov cub iav:

Cov khoom tseem ceeb: SiO2 thiab Al2O3, tab sis cov ntsiab lus Al2O3 yuav tsum ntau dua 46%. Kub ua haujlwm: Qhov kub siab tshaj plaws yog 1500 ~ 1650 ℃. Nta: Zoo tiv taus xeb, thiab tuaj yeem tiv taus xeb los ntawm ob qho tib si acidic thiab alkaline slags. Feem ntau siv rau hauv cov chav cia cua sov, nrog rau cov khoom siv refractory rau cov pas dej ua haujlwm, cov khoom siv thiab cov pub mis.

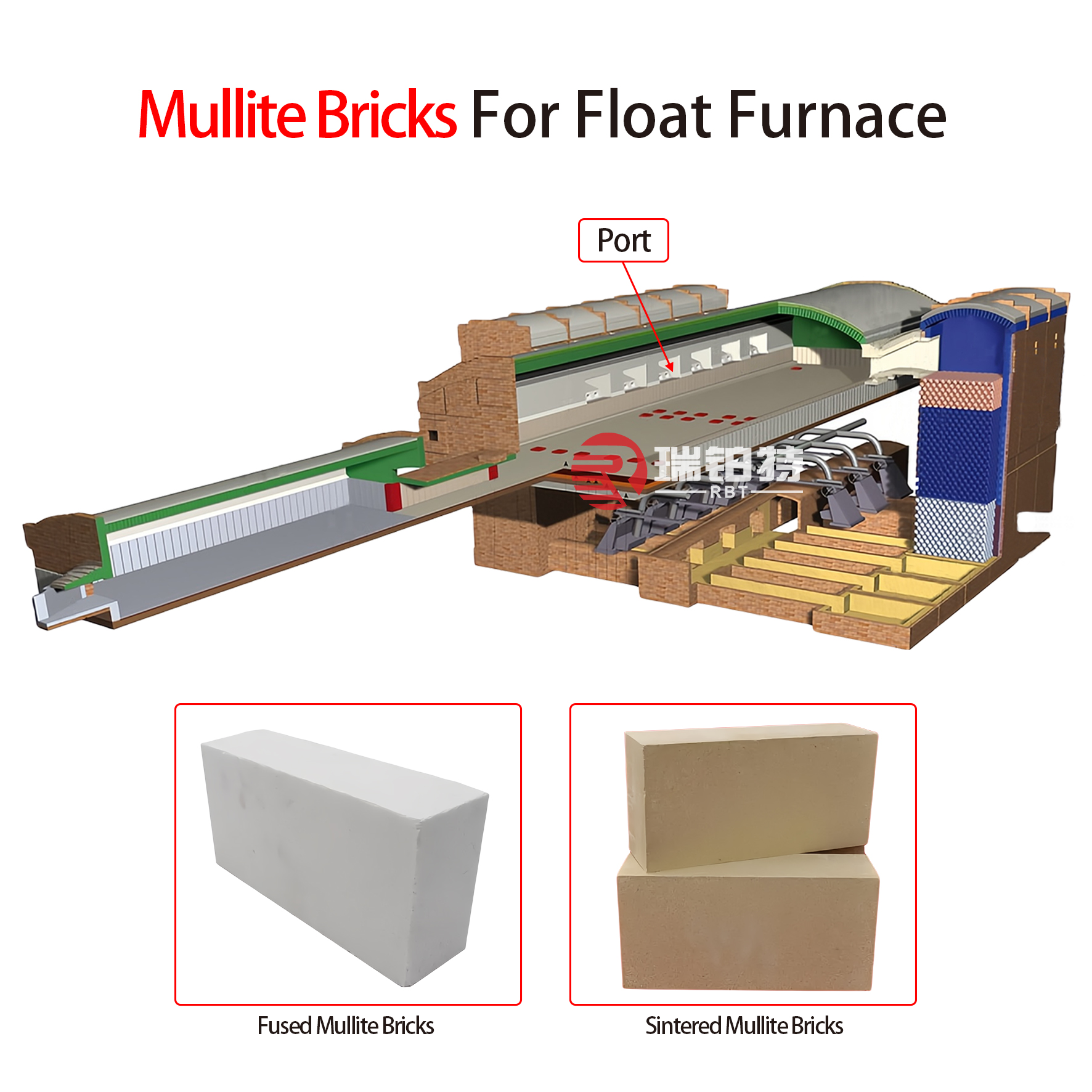

Cov cib mullite:

Cov khoom tseem ceeb ntawm cov cib mullite yog Al2O3, thiab nws cov ntsiab lus yog li 75%. Vim tias nws feem ntau yog cov siv lead ua mullite, nws hu ua cov cib mullite. Qhov ceev 2.7-3 2g / cm3, qhib porosity 1% -12%, thiab qhov kub ua haujlwm siab tshaj plaws yog 1500 ~ 1700 ℃. Sintered mullite feem ntau yog siv rau kev ua masonry ntawm cov phab ntsa cia cua sov. Fused mullite feem ntau yog siv rau kev ua masonry ntawm cov phab ntsa pas dej ua ke, qhov chaw soj ntsuam, phab ntsa buttresses, thiab lwm yam.

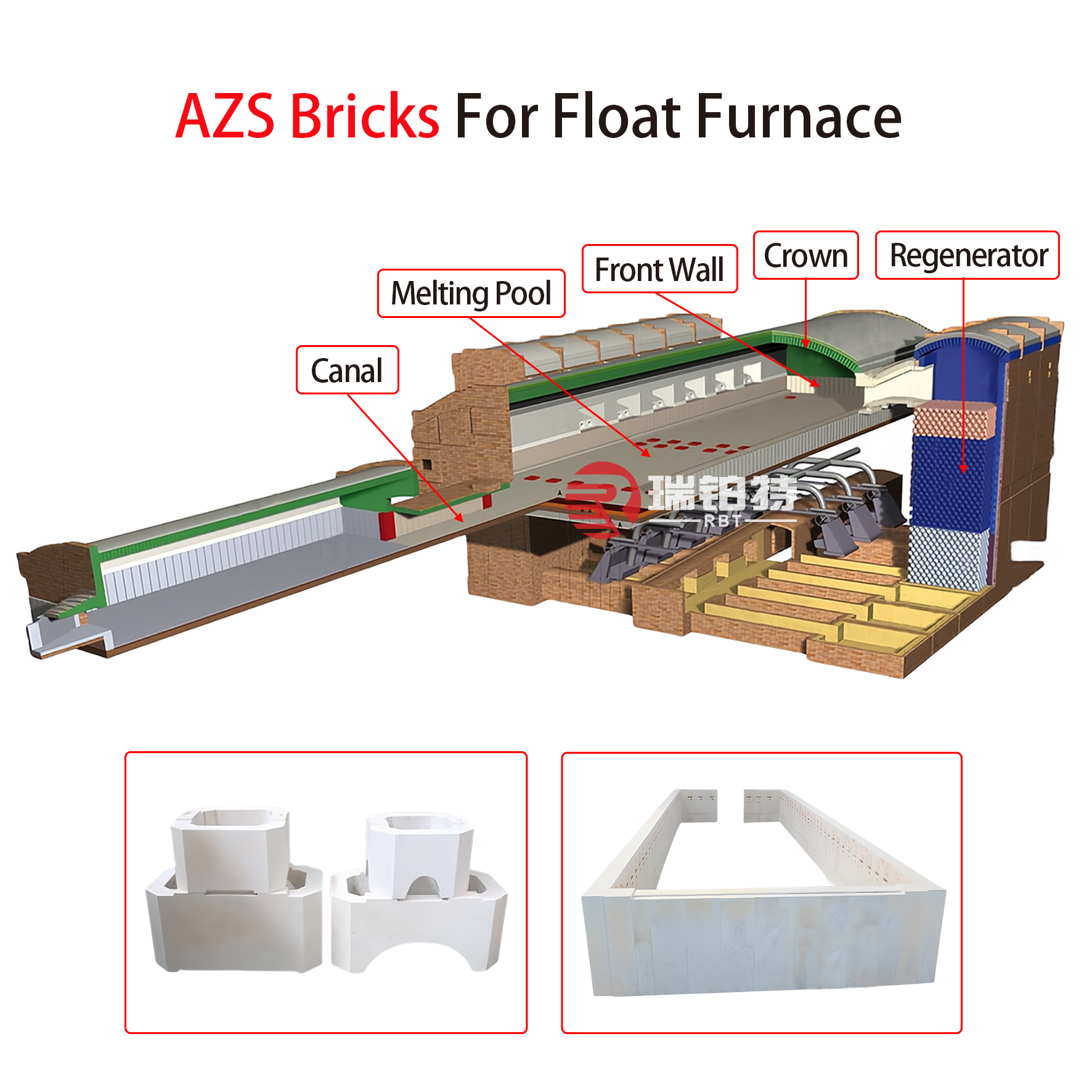

Cov cib fim ntawm zirconium corundum fused:

Cov cib fim zirconium corundum uas tau sib xyaw ua ke kuj hu ua cov cib fim hlau dawb. Feem ntau, cov cib fim zirconium corundum uas tau sib xyaw ua ke raug muab faib ua peb qib raws li cov ntsiab lus zirconium: 33%, 36%, thiab 41%. Cov cib fim zirconium corundum uas siv hauv kev lag luam iav muaj 50% ~ 70% Al2O3 thiab 20% ~ 40% ZrO2. Qhov ceev yog 3.4 ~ 4.0g / cm3, qhov pom tseeb porosity yog 1% ~ 10%, thiab qhov kub siab tshaj plaws yog li 1700 ℃. Cov cib fim zirconium corundum uas tau sib xyaw ua ke nrog cov ntsiab lus zirconium ntawm 33% thiab 36% yog siv los tsim cov phab ntsa pas dej ua ke, cov phab ntsa qhov chaw nplaim taws, cov qhov me me ntawm lub cub tawg, cov qhov cub me me ntawm lub cub tawg, cov qhov cub me me ntawm lub cub tawg, cov qhov nplaig, thiab lwm yam. Cov cib fim zirconium corundum uas tau sib xyaw ua ke nrog cov ntsiab lus zirconium ntawm 41% yog siv los tsim cov ces kaum phab ntsa pas dej ua ke, cov qhov dej ntws, thiab lwm qhov chaw uas cov kua iav lwj thiab xeb cov khoom siv refractory feem ntau. Cov khoom siv no yog cov khoom siv refractory fused cast feem ntau siv hauv kev lag luam iav.

Cov cib fim alumina fused:

Nws feem ntau yog hais txog fused α, β corundum, thiab fused β corundum refractory bricks, uas feem ntau yog tsim los ntawm 92% ~ 94% Al2O3 corundum crystal phase, qhov ceev 2.9 ~ 3.05g / cm3, pom tseeb porosity 1% ~ 10%, thiab qhov kub ua haujlwm siab tshaj plaws ntawm kwv yees li 1700 ℃. Fused alumina muaj kev tiv thaiv zoo heev rau iav permeation thiab yuav luag tsis muaj kuab paug rau iav kua. Nws yog dav siv rau hauv qhov chaw ua haujlwm ntawm phab ntsa pas dej ua ke, hauv qab pas dej ua ke, ntws channel, ua haujlwm ntawm cov khoom siv channel pas dej ua ke phab ntsa, cov khoom siv channel pas dej ua ke hauv qab thiab lwm qhov ntawm lub qhov cub iav yaj uas kov cov iav kua thiab tsis xav tau kev ua qias tuaj refractory.

Cov pob zeb quartz:

Lub ntsiab tivthaiv yog SiO2, uas muaj ntau tshaj 99%, nrog rau qhov ceev ntawm 1.9 ~ 2g / cm3, qhov refractoriness ntawm 1650 ℃, qhov kub ua haujlwm ntawm kwv yees li 1600 ℃, thiab tiv taus acid erosion. Nws yog siv los tsim phab ntsa pas dej ua ke ntawm acidic boron iav, nplaim taws qhov thermocouple qhov cib, thiab lwm yam.

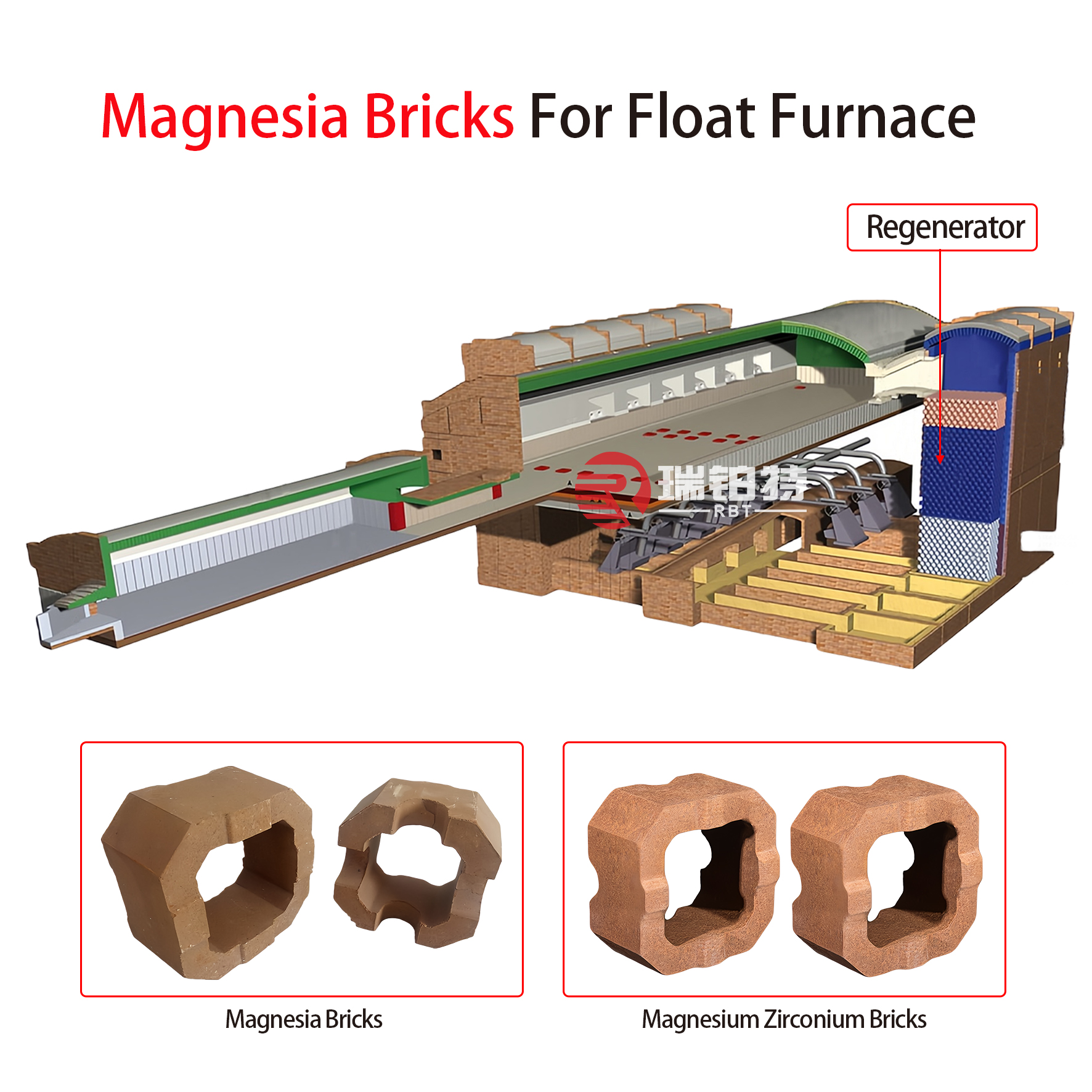

Cov ntaub ntawv refractory alkaline:

Cov khoom siv alkaline refractory feem ntau yog hais txog cov cib magnesia, cov cib alumina-magnesia, cov cib magnesia-chrome, thiab cov cib forsterite. Nws cov kev ua tau zoo yog los tiv thaiv kev yaig ntawm cov khoom alkaline, thiab nws qhov refractoriness yog 1900 ~ 2000 ℃. Nws yog dav siv rau hauv phab ntsa sab saud ntawm lub tshuab rov ua dua ntawm lub cub tawg iav, lub qhov rooj rov ua dua tshiab, lub cev grid, thiab cov qauv me me ntawm lub cub tawg.

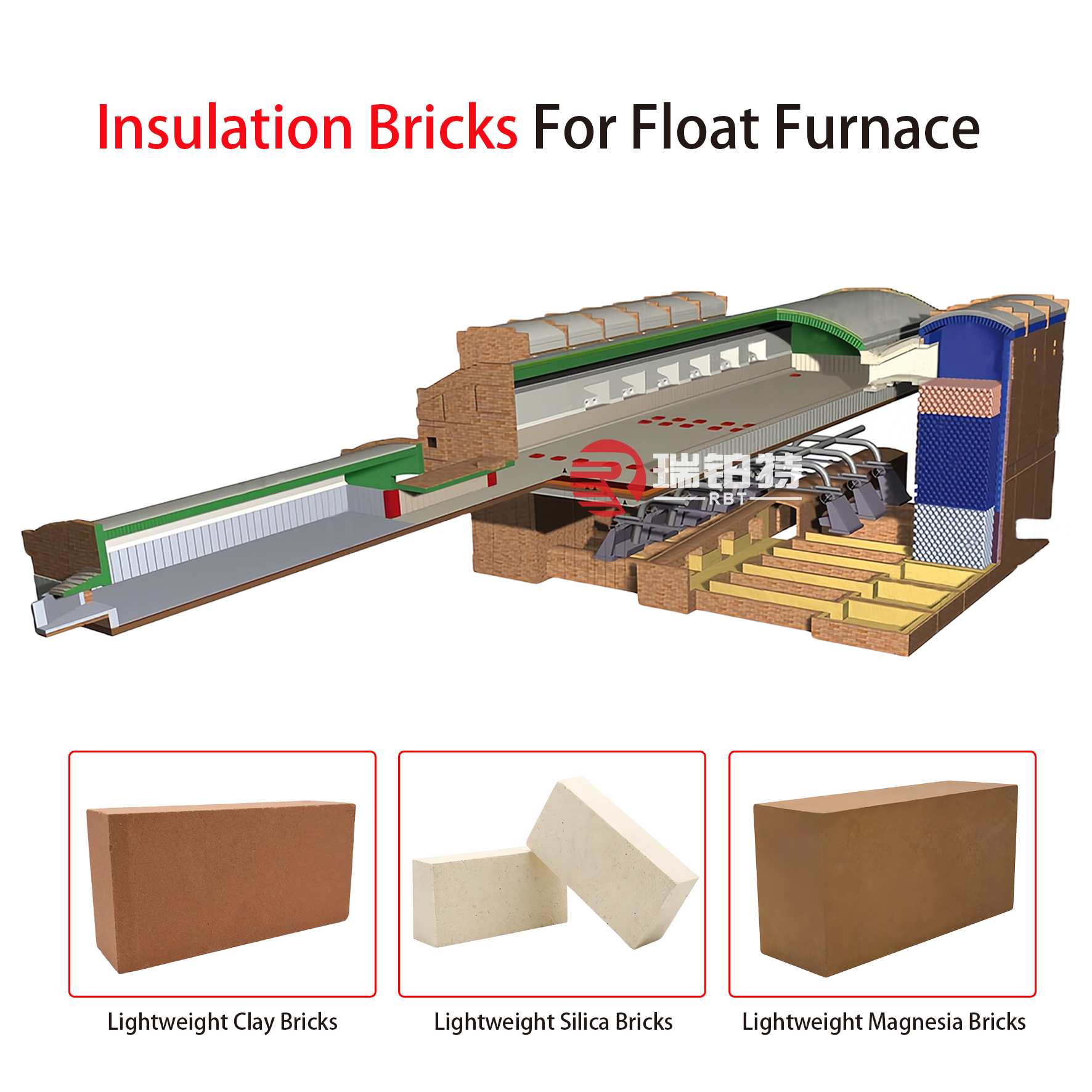

Cov cib rwb thaiv tsev rau cov cub tawg iav:

Lub cheeb tsam cua sov ntawm lub cub tawg iav yaj yog qhov loj thiab qhov ua haujlwm thermal tsawg. Yuav kom txuag tau hluav taws xob thiab txo kev siv, yuav tsum muaj ntau cov khoom siv rwb thaiv tsev rau kev rwb thaiv tsev kom tiav. Tshwj xeeb, phab ntsa pas dej ua ke, hauv qab pas dej ua ke, lub qhov rooj, thiab phab ntsa hauv lub tshuab rov ua dua tshiab, qhov chaw yaj, qhov chaw ua haujlwm, thiab lwm yam yuav tsum tau rwb thaiv tsev kom txo qhov cua sov. Lub porosity ntawm lub cib rwb thaiv tsev loj heev, qhov hnyav yog sib dua, thiab qhov ceev tsis tshaj 1.3g / cm3. Txij li thaum kev ua haujlwm hloov pauv cua sov ntawm huab cua tsis zoo heev, lub cib rwb thaiv tsev nrog lub porosity loj muaj cov nyhuv rwb thaiv tsev. Nws cov coefficient thermal conductivity yog 2 ~ 3 zaug qis dua li cov ntaub ntawv refractory dav dav, yog li qhov loj dua qhov porosity, qhov zoo dua qhov rwb thaiv tsev. Muaj ntau hom cib rwb thaiv tsev sib txawv, suav nrog cov cib rwb thaiv tsev av nplaum, cov cib rwb thaiv tsev silica, cov cib rwb thaiv tsev alumina siab thiab lwm yam.

Lub sijhawm tshaj tawm: Plaub Hlis-25-2025