Mosi2 Cuab Yeej

Cov ntaub ntawv khoom

Mosi2 cua sov caijyog ib hom kev tiv thaiv cua sov lub hauv paus ua los ntawm siab ntshiab Molybdenum Disilicide. Nyob rau hauv oxidizing huab cua, ib txheej ntawm compact quartz tiv thaiv zaj duab xis yog tsim nyob rau saum npoo ntawm Mosi2 elementowing mus rau kub kub combustion, uas tiv thaiv Mosi2 tsis tu ncua oxidizing. Nyob rau hauv oxidizing cua, nws qhov kub siab tshaj plaws tuaj yeem ncav cuag 1800'C, thiab nws qhov ntsuas kub yog 500-1700'C. Nws tuaj yeem siv dav hauv cov ntawv thov xws li sintering thiab kev kho cua sov ntawm ceramics, hlau nplaum, iav, metallurgy, refractory, thiab lwm yam.

Nta:

1. Kev kub siab ua haujlwm zoo

2. Muaj zog oxidation tsis kam

3. Muaj zog txhua yam

4. Cov khoom siv hluav taws xob zoo

5. Muaj zog corrosion kuj

Lub cev muaj zog

| Volume Ceev | Khoov zog | Vickers-Hadness |

| 5.5-5.6kg / cm3 | 15-25kg / cm2 | (HV) 570kg/mm2 |

| Porosity tus nqi | Kev nqus dej | Kub Extensibility |

| 7.4% | 1.2% | 4% |

Cov duab ntxaws

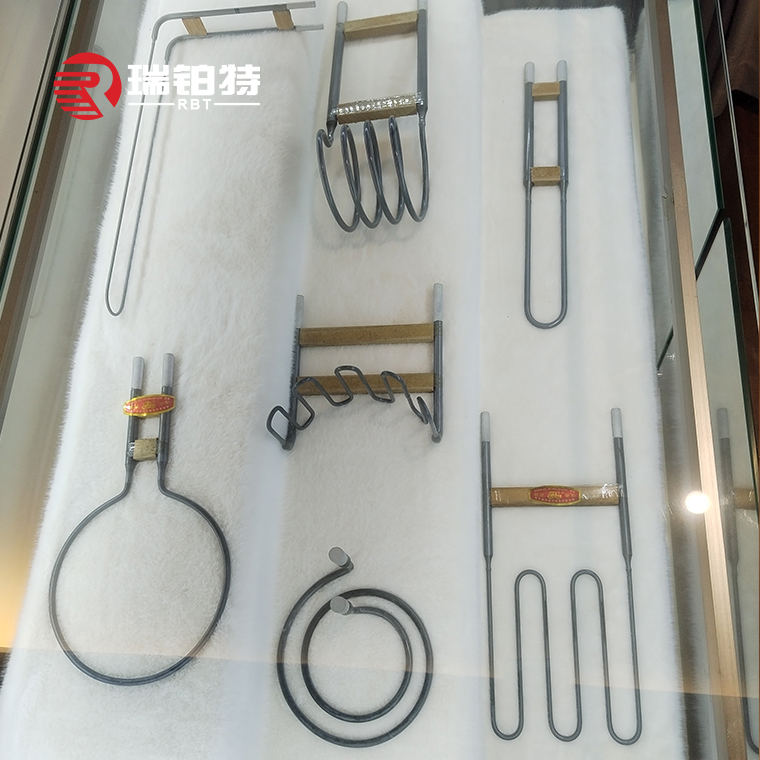

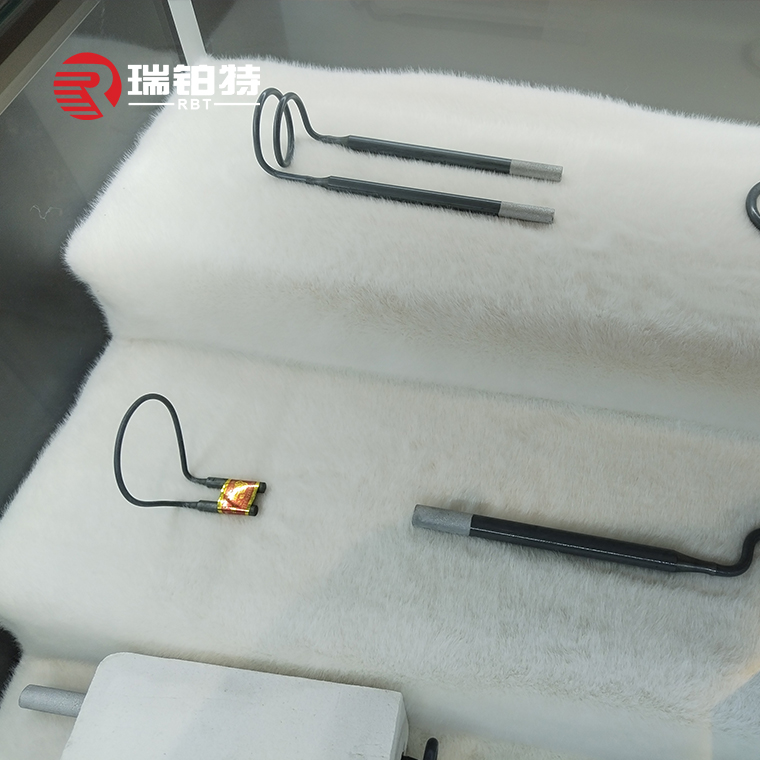

covU-shaped silicon molybdenum pas nrig:Qhov no yog ib qho ntawm feem ntau siv cov duab. Qhov tsim ob-kauj ruam ua rau nws dav siv nyob rau hauv high-temperature electric furnaces thiab feem ntau yog siv nyob rau hauv ntsug suspension. cov

Lub kaum sab xis silicon molybdenum pas nrig:Haum rau cov khoom siv cua sov uas yuav tsum tau muaj lub kaum sab xis. cov

I-type silicon molybdenum pas nrig:Haum rau linear cua sov xav tau.

cov

W-hom silicon molybdenum pas nrig:Haum rau thaj chaw uas xav tau cua sov wavy. cov

Tshwj xeeb-puab silicon molybdenum pas nrig:Xws li muab kauv, ncig thiab ntau cov duab khoov, thiab lwm yam, haum rau cov cua sov xav tau ntawm cov duab tshwj xeeb.

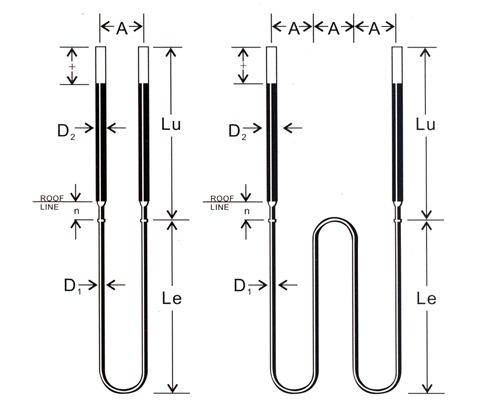

Standard Diameter Size Rau MoSi2 Muffle Rauv Cua Sov Element

M1700 Hom (d / c):3/6, 4/9, 6/12, 9/18, 12/24 M1800 Hom (d / c):3/6, 4/9, 6/12, 9/18, 12/24(1) Le: Ntev ntawm Qhov Chaw Kub Kub(2) Lu: Ntev ntawm Qhov Chaw Txias(3) D1: Txoj kab uas hla ntawm Chaw Kub Kub(4) D2: Txoj kab uas hla ntawm Thaj Chaw Txias(5) A: Qhov sib txawv ntawm ShankThov qhia rau peb paub cov ntaub ntawv no thaum koj book ib qho kev txiav txim rau MoSi2 muffle furnace cua sov caij.

| Txoj kab uas hla ntawm Hot Zone | Txoj kab uas hla ntawm Cold Zone | Ntev ntawm Qhov Chaw Kub Kub | Length ntawm Cold Zone | Shank Spacing |

| 3mm ib | 6mm ib | 80-300 hli | 80-500 hli | 25 hli |

| 4mm ib | 9mm ib | 80-350 hli | 80-500 hli | 25 hli |

| 6mm ib | 12 hli | 80-800 hli | 80-1000 hli | 25-60 hli |

| 7mm ib | 12 hli | 80-800 hli | 80-1000 hli | 25-60 hli |

| 9mm ib | 18 hli | 100-1200 hli | 100-2500 hli | 40-80 hli |

| 12 hli | 24mm ib | 100-1500 hli | 100-1500 hli | 40-100 hli |

Qhov txawv ntawm 1800 thiab 1700

(1) Lub vuam sib txuas ntawm 1800 silicon molybdenum pas nrig yog tag nrho, protruding thiab bulging, thiab tsis muaj qhov tawg ntawm qhov chaw vuam, uas txawv ntawm 1700 hom.

(2) Qhov saum npoo ntawm 1800 silicon molybdenum pas nrig yog smoother thiab muaj xim hlau luster.

(3) Lub ntiajteb txawj nqus yog siab dua. Piv nrog rau 1700 hom, 1800 silicon molybdenum pas nrig ntawm tib lub ntsiab lus yuav hnyav dua.

(4) Cov xim sib txawv. Yuav kom saib zoo, qhov chaw ntawm 1700 silicon molybdenum pas nrig yog kho thiab zoo li dub.

(5) Kev khiav hauj lwm tam sim no thiab qhov hluav taws xob ntawm 1800 silicon molybdenum pas nrig yog me dua li ntawm 1700 hom. Rau tib qhov kub kawg 9 lub caij, qhov kev khiav hauj lwm tam sim no ntawm 1800 hom yog 220A, thiab cov khoom ntawm 1700 degree yog txog 270A.

(6) Kev khiav hauj lwm kub yog siab, uas yog ntau tshaj 100 degrees siab tshaj li ntawm 1700 degree.

(7) Kev siv dav dav:

1700 Hom: feem ntau yog siv nyob rau hauv industrial tshav kub kho rauv, sintering furnaces, casting furnaces, iav melting furnaces, smelting furnaces, thiab lwm yam.

1800 Hom: Feem ntau yog siv rau hauv qhov chaw sim, cov cuab yeej ntsuas thiab cov cua kub kub sintering, thiab lwm yam.

| Qhov kub siab tshaj plaws ntawm cov ntsiab lus nyob rau hauv txawv Atmospheres | ||

| Huab cua | Max Element Kub | |

| 1700 Ib | 1800 Ib | |

| Cua | 1700 ℃ | 1800 ℃ |

| Nitrogen | 1600 ℃ | 1700 ℃ |

| Argon, Helium | 1600 ℃ | 1700 ℃ |

| Hydrogen | 1100-1450 ℃ | 1100-1450 ℃ |

| N2/H2 95/5% | 1250-1600 ℃ | 1250-1600 ℃ |

Daim ntawv thov

Metallurgy:Siv nyob rau hauv steel smelting thiab refining los pab ua kom tiav high-temperature melting.

Glass Manufacturing:Raws li cov khoom siv hluav taws xob rau hluav taws xob hluav taws xob hluav taws xob thiab cov hluav taws xob hnub ci, nws yog siv los tsim cov khoom siv iav zoo.

Kev lag luam ceramic:Xyuas kom muaj kev sib tsoo zoo thiab cov khoom siv hluav taws xob zoo tshaj plaws hauv cov khoom siv ceramic.

Kev lag luam Electronic:Siv los tsim cov khoom siv hluav taws xob kub kub thiab cov khoom siv, xws li thermocouple tiv thaiv raj.

Aerospace:Raws li ib qho tseem ceeb ntawm cov cua sov thiab kub tswj systems nyob rau hauv high-temperature ib puag ncig.

metallurgy

Kev tsim iav

Kev lag luam ceramic

Kev lag luam hluav taws xob

Pob & Warehouse

Tuam txhab Profile

Shandong Robert Tshiab Khoom Co., Ltd.yog nyob rau hauv Zibo City, Shandong xeev, Suav teb, uas yog ib tug refractory khoom tsim los puag. Peb yog ib lub tuam txhab niaj hnub uas koom nrog kev tshawb fawb thiab kev tsim kho, kev tsim khoom, muag, kiln tsim thiab kev tsim kho, thev naus laus zis, thiab xa tawm cov ntaub ntawv refractory. Peb muaj cov cuab yeej ua tiav, cov thev naus laus zis siab heev, muaj zog technical, cov khoom zoo heev, thiab lub koob npe zoo. Peb lub Hoobkas npog ntau tshaj 200 daim av thiab cov khoom tsim tawm txhua xyoo ntawm cov khoom siv refractory yog kwv yees li 30000 tons thiab cov ntaub ntawv tsis zoo yog 12000 tons.

Peb cov khoom tseem ceeb ntawm cov ntaub ntawv refractory muaj xws li:alkaline refractory khoom; aluminium silicon refractory cov ntaub ntawv; unshaped refractory khoom; rwb thaiv tsev thermal refractory cov ntaub ntawv; cov ntaub ntawv tshwj xeeb refractory; functional refractory cov ntaub ntawv rau nruam casting tshuab.

Cov lus nug nquag

Xav tau kev pab? Nco ntsoov mus saib peb lub rooj sab laj kev txhawb nqa rau cov lus teb rau koj cov lus nug!

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov ntaub ntawv refractory rau ntau tshaj 30 xyoo. Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov zoo tshaj plaws ua ntej muag thiab kev pab cuam tom qab muag.

Rau txhua tus txheej txheem tsim khoom, RBT muaj kev ua tiav QC rau cov tshuaj muaj pes tsawg leeg thiab lub cev muaj zog. Thiab peb yuav kuaj cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom. Yog tias koj muaj cov cai tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws kom haum lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv. Tab sis peb cog lus tias yuav nkoj sai li sai tau nrog lav zoo.

Tau kawg, peb muab cov qauv dawb.

Yog lawm, tau kawg, txais tos tuaj xyuas RBT tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov ntaub ntawv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb zog thiab kev nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov khoom sib txawv thiab muab kev pabcuam ib-nres.