Silicon Carbide Dryer Lgniter

Yam khoom

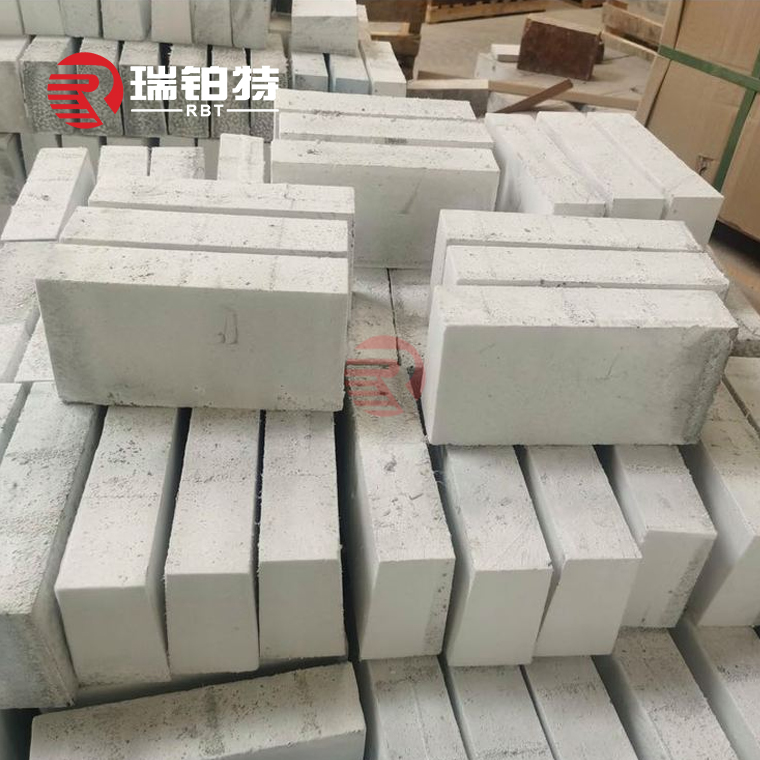

1. Cov tshuaj tiv thaiv sintered silicon carbide khoom (RBSiC khoom)

Reaction bonded silicon carbide (RBSiC) yog cov khoom siv hluav taws xob zoo tshaj plaws uas tsim cov silicon carbide bonding theem los ntawm kev ua pa dawb nrog cov kua silicon nyob rau hauv qhov kub thiab txias. Nws cov khoom tseem ceeb suav nrog silicon carbide (SiC) matrix thiab silicon dawb (Si). Cov qub muab cov khoom siv zoo heev, hnav tsis kam thiab kub kub stability,

thaum lub sij hawm tom kawg sau cov pores ntawm silicon carbide hais los txhim kho qhov ceev thiab kev ncaj ncees ntawm cov khoom.

(1) Cov yam ntxwv:

Kub kub stability:Ua haujlwm kub siab tshaj 1350 ℃.

Hnav tsis kam thiab corrosion kuj:Haum rau kev ua haujlwm hnyav ntawm kub, kua qaub, alkali thiab molten hlau. cov

High thermal conductivity thiab qis thermal expansion coefficient:Lub thermal conductivity yog siab li 120-200 W / (m·K), thiab thermal expansion coefficient tsuas yog 4.5 × 10⁻⁶ K⁻¹, uas zoo tiv thaiv thermal tawg thiab thermal qaug zog. cov

Anti-oxidation:Ib txheej tuab silica tiv thaiv yog tsim rau saum npoo ntawm qhov kub thiab txias kom ntev lub neej kev pab cuam.

(2) Cov khoom tseem ceeb:

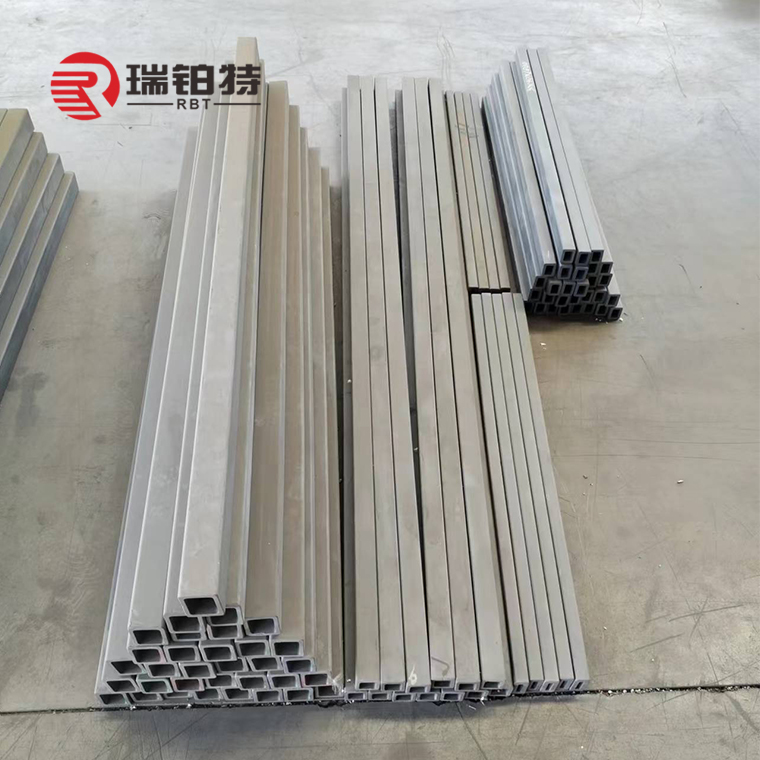

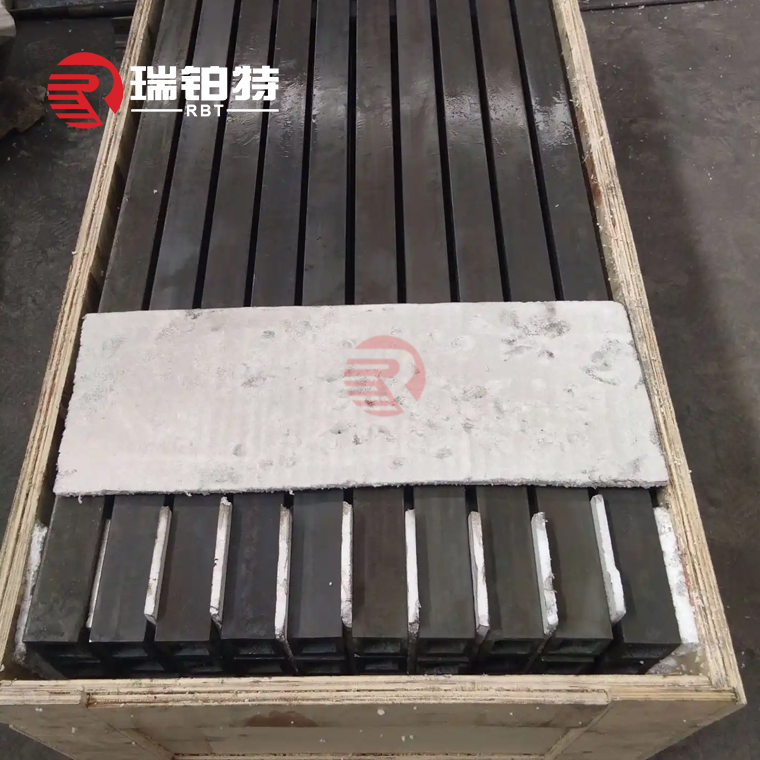

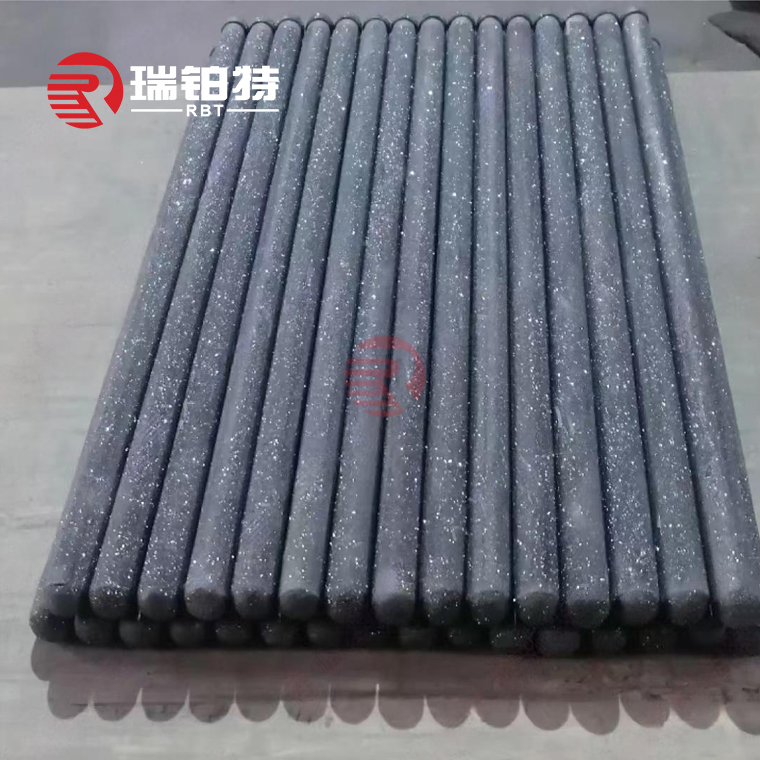

covSilicon carbide beam:siv rau cov qauv load-bearing ntawm tunnel kilns, shuttle kilns thiab lwm yam kev lag luam kilns, nrog zoo heev kub kuj.

cov

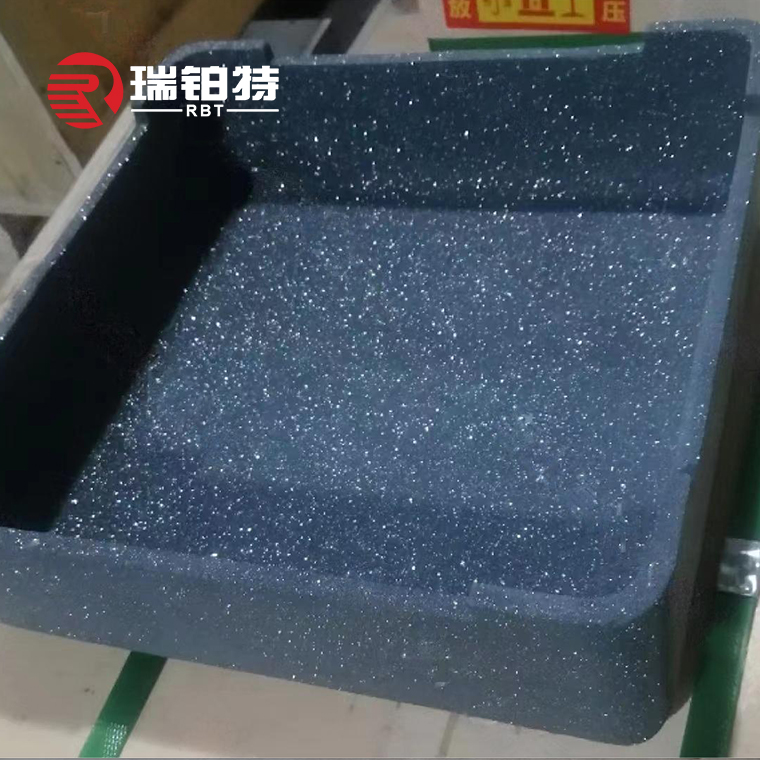

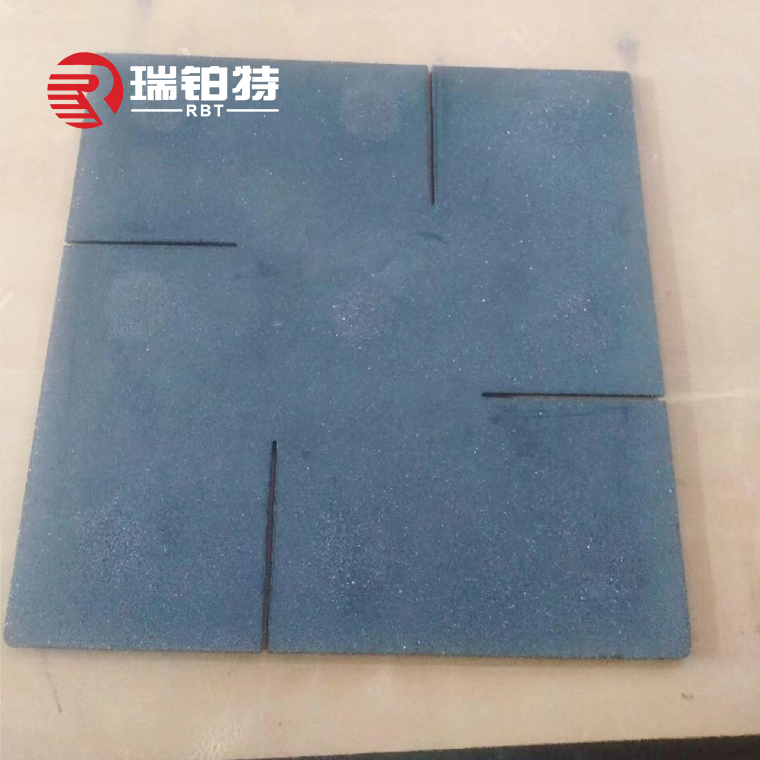

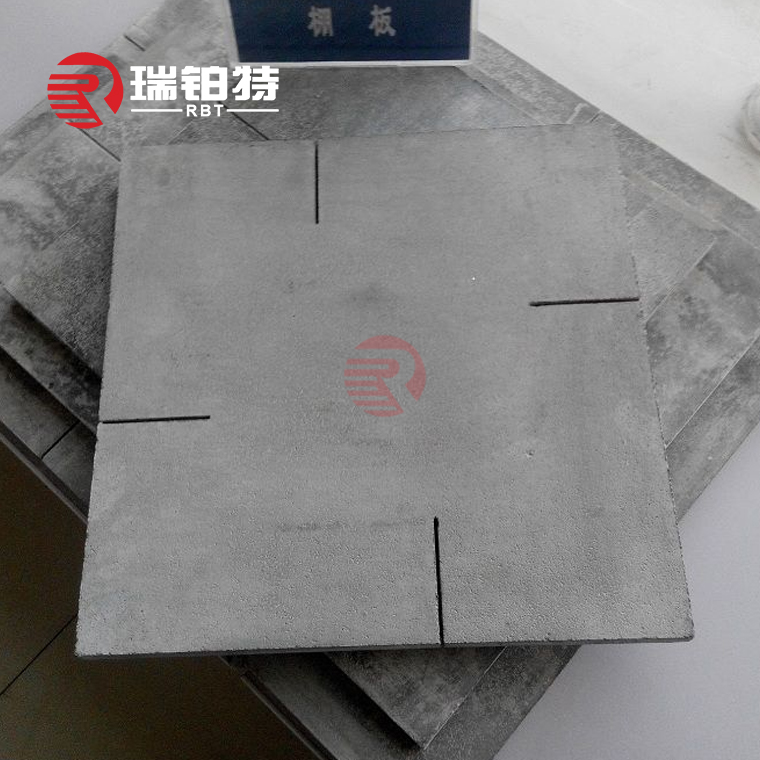

Silicon carbide phaj:siv rau cov ntaub ntawv refractory nyob rau hauv kiln, nrog rau cov yam ntxwv ntawm oxide bonding. cov

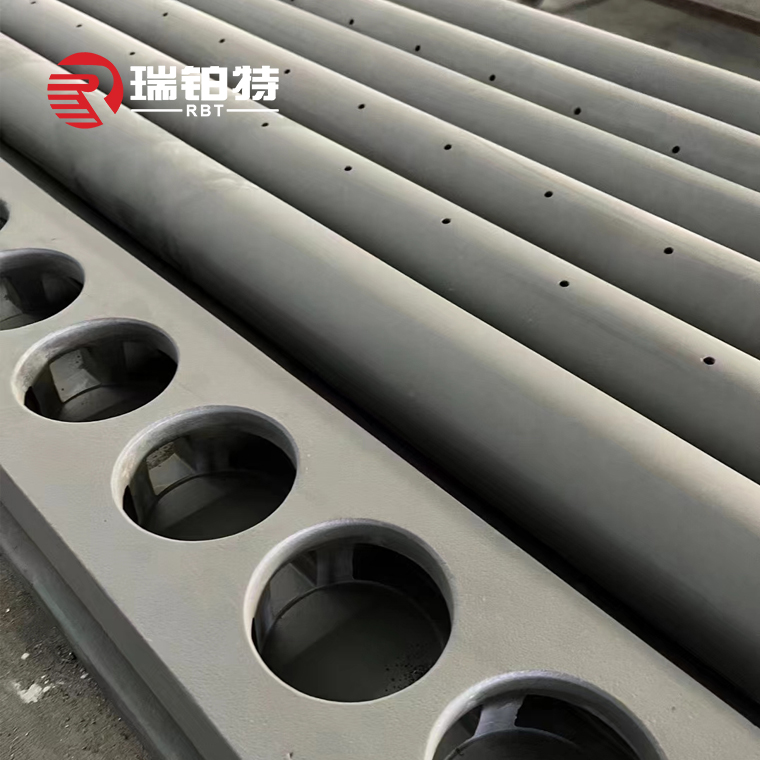

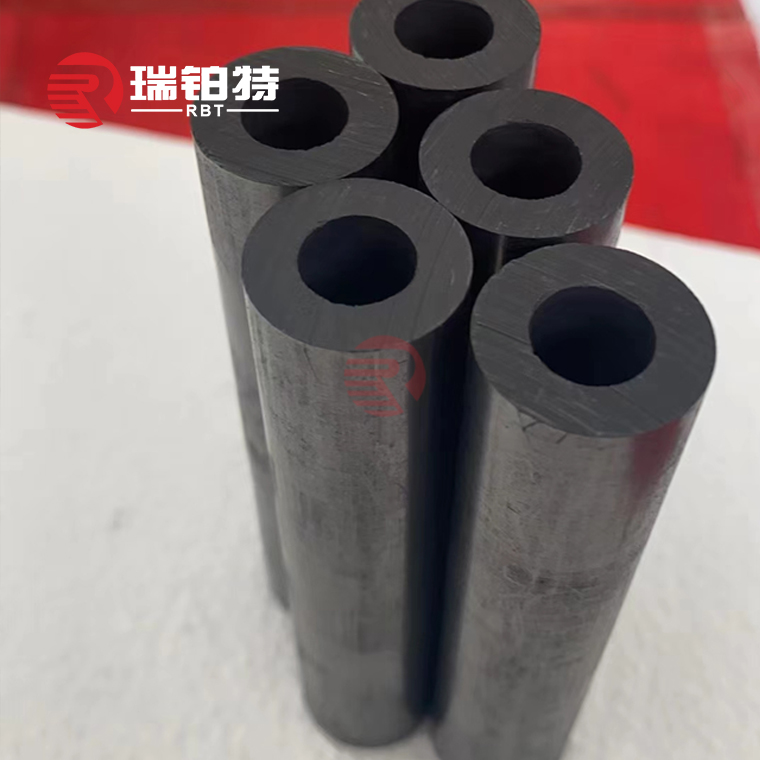

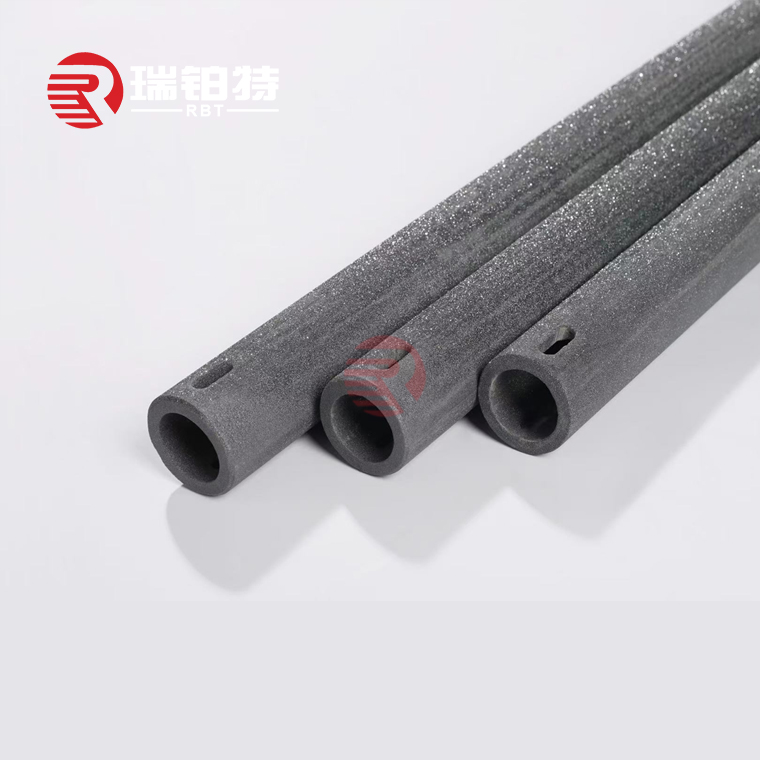

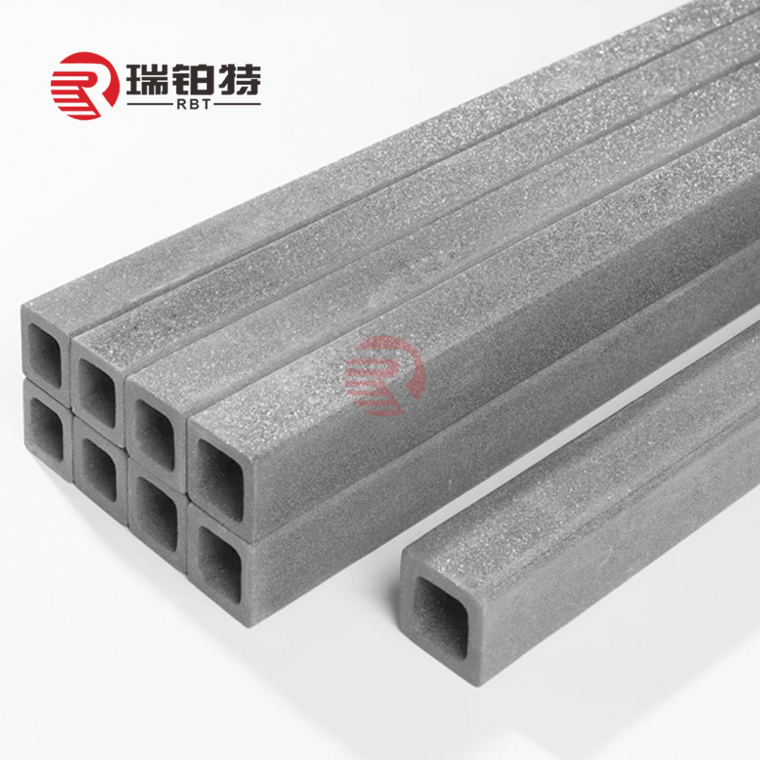

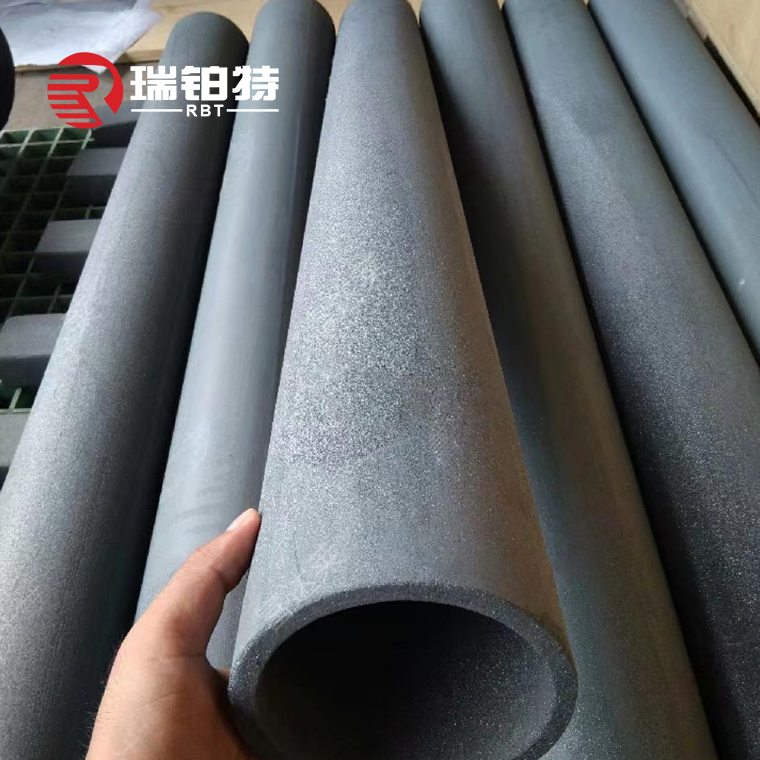

Silicon carbide yeeb nkab:siv rau cov kav dej thiab ntim khoom hauv ntau qhov chaw kub kub. cov

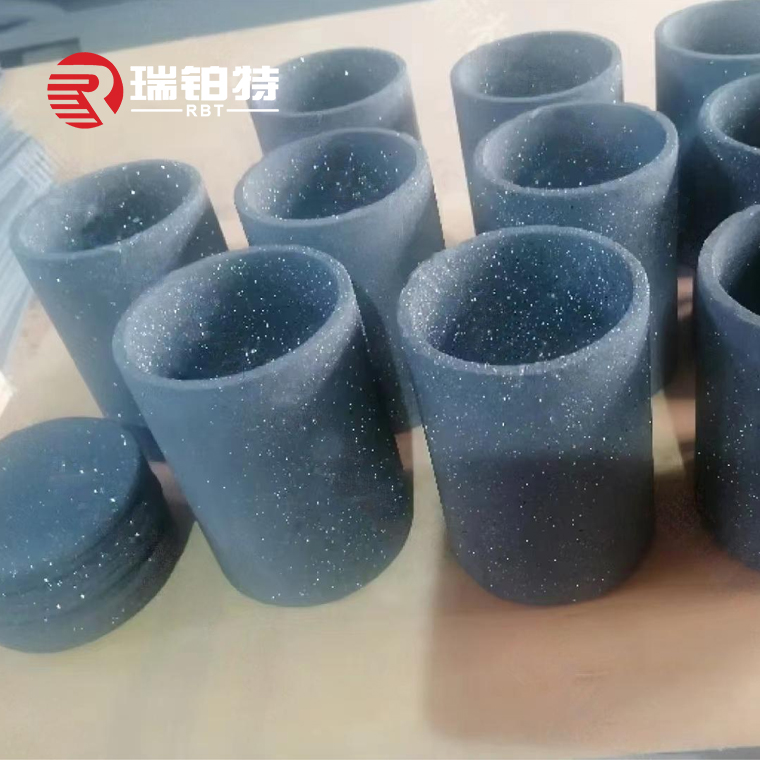

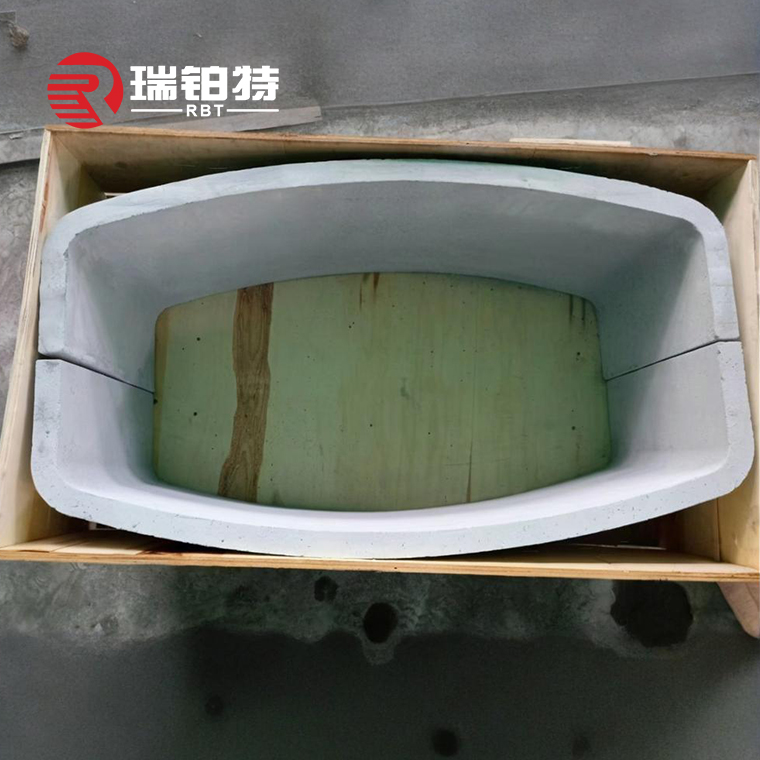

Silicon carbide crucible thiab sagger:siv rau kub smelting thiab cia cov ntaub ntawv. cov

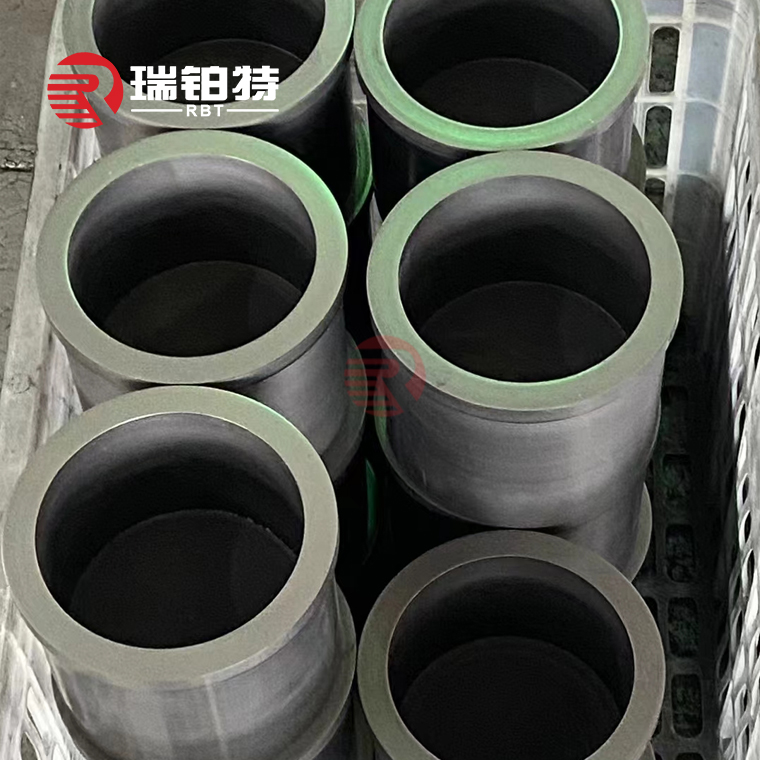

Silicon carbide foob nplhaib:dav siv nyob rau hauv lub teb ntawm tsheb, aerospace thiab tshuaj lom neeg kev lag luam, thiab muaj peev xwm tswj tau txhim khu kev qha sealing kev ua tau zoo nyob rau hauv kub kub thiab siab kub ib puag ncig. cov

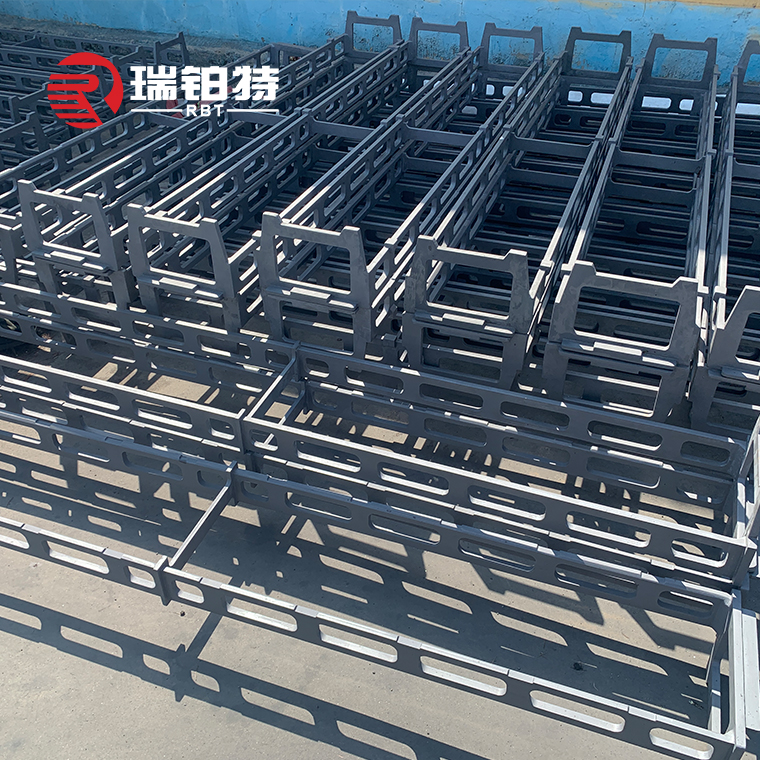

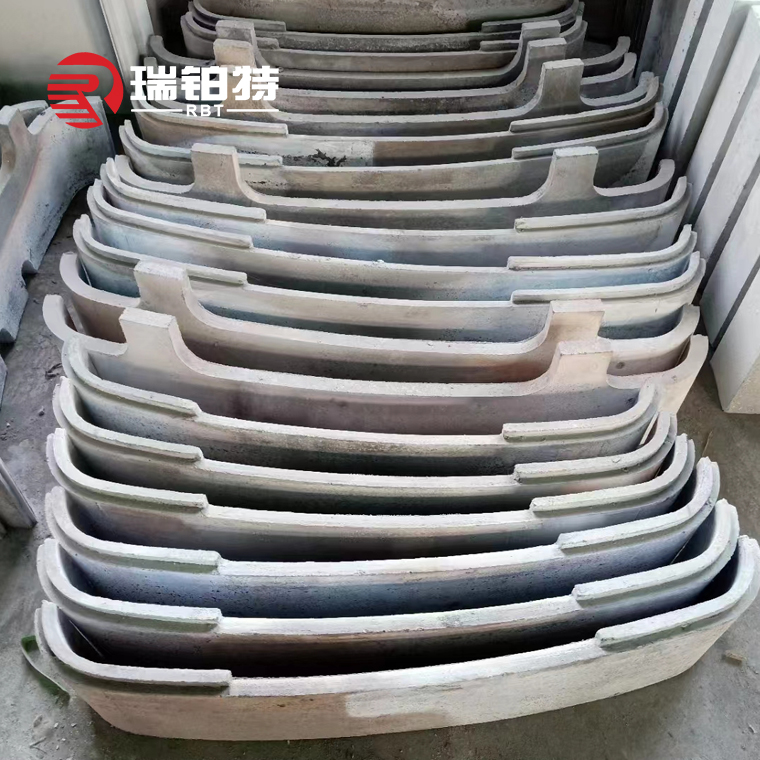

Silicon carbide cov menyuam:siv rau cov menyuam kilns, nrog cov yam ntxwv ntawm kev tiv thaiv oxidation, siab kub flexural zog thiab kev pab lub neej ntev. cov

Silicon carbide cua txias kav:siv rau qhov chaw txias ntawm cov menyuam kilns, nrog kev ua haujlwm zoo rau huab cua

txias thiab kub. cov

Silicon carbide bunner nozzle:siv rau ntau yam roj, roj thiab lwm yam kev lag luam kiln, nrog rau cov yam ntxwv ntawm huab cua txias thiab kub tsis kam, hnav tsis kam, kub tsis kam, thiab lwm yam. cov

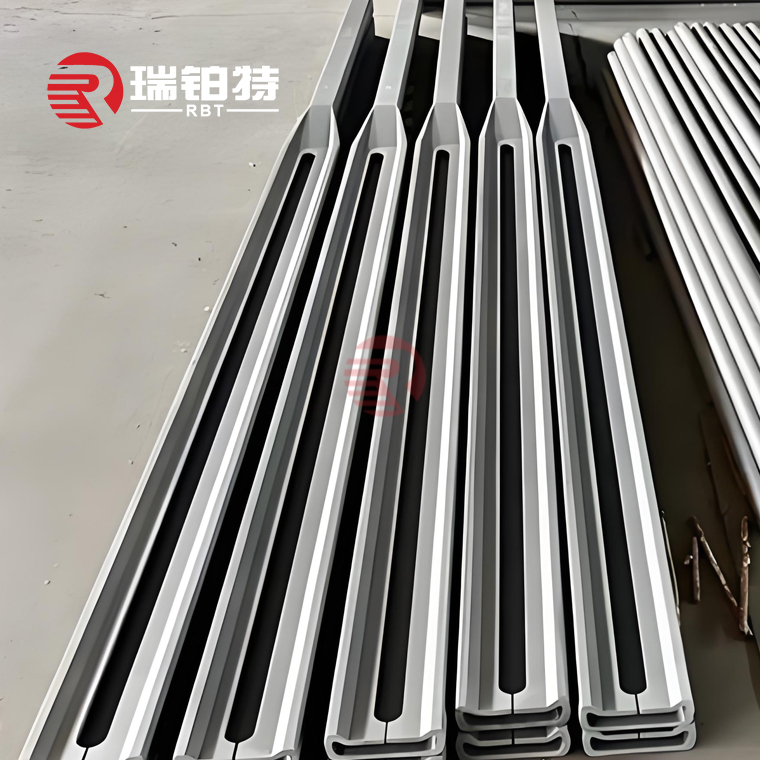

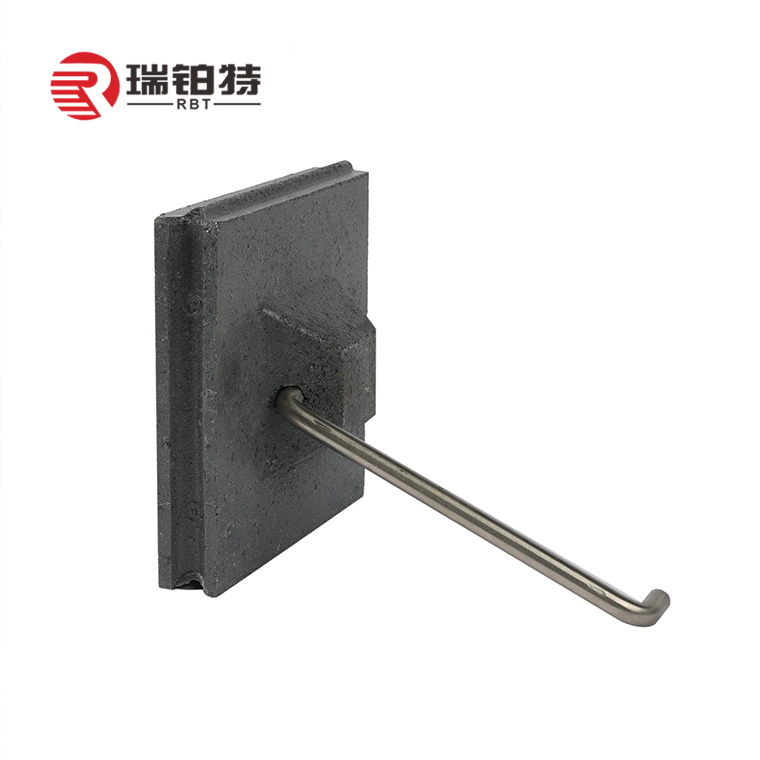

Customized tshwj xeeb-puab qhov chaw:Customized ntau lawm ntawm ntau yam tshwj xeeb-puab qhov chaw raws li cov neeg xav tau kev pab, xws li ntses-puab daim hlau, dai rods, txhawb qhov chaw, thiab lwm yam.

Cov duab ntxaws

Silicon Carbide Beam

Silicon Carbide Cantilever Paddle

Silicon Carbide Nozzle

Silicon Carbide Burner Tube

Silicon Carbide Cooling Pipes

Silicon Carbide Nozzle

Silicon Carbide Boat Bracket

Hnav-resistant hauv ob sab phlu

Silicon Carbide Wafer Nkoj

Product Index

| RBSiC (SiSiC) cov khoom | ||

| Yam khoom | Chav tsev | Cov ntaub ntawv |

| Max kub ntawm daim ntawv thov | ℃ | ≤1350 |

| Qhov ntom | g/cm3 | ≥3.02 |

| Qhib Porosity | % | ≤0.1 |

| Khoov zog | Mpa | 250 (20 ℃); 280 (1200 ℃) |

| Modulus ntawm Elastictiy | Gpa | 330 (20 ℃); 300 (1200 ℃) |

| Thermal conductivity | W/mk | 45 (1200 ℃) |

| Thermal Expansion Coefficient | K-1 * 10-6 | 4.5 |

| Moh's Hardness | | 9.15 Nws |

| Acid Alkaline-pov thawj | | Zoo heev |

2. Pressureless sintered silicon carbide khoom (SSiC khoom)

Cov khoom siv tsis muaj zog sintered silicon carbide yog ib yam khoom siv high-tech ceramic npaj los ntawm cov txheej txheem pressureless sintering. Nws cov khoom tseem ceeb yog silicon carbide (SiC), thiab ib qho kev faib ua feem ntawm cov khoom siv ntxiv. Los ntawm cov thev naus laus zis thev naus laus zis, nws tau ua rau hauv cov khoom tsis muaj qhov ntxeem tau, seamless, thiab tsis muaj kev ntxhov siab tsis muaj kev kub ntxhov siab.

(1) Cov yam ntxwv:

Kub kub kuj:ib txwm siv ntawm 1800 ℃;

High thermal conductivity:sib npaug rau thermal conductivity ntawm graphitecov ntaub ntawv;

Siab hardness:hardness yog thib ob tsuas yog pob zeb diamond thiab cubic boron nitride;

Corrosion kuj:muaj zog acid thiab muaj zog alkali tsis muaj corrosion rau nws, thiab nws cov corrosion kuj zoo dua tungsten carbide thiab txhuas oxide;

Lub teeb yuag:ceev 3.10g / cm3, ze rau txhuas;

Tsis muaj deformation:me me thermal expansion coefficient,

Resistant rau thermal shock:Cov khoom siv tuaj yeem tiv taus qhov kub thiab txias hloov ceev, thermal poob siab, ceev ceev txias thiab cua sov, thiab muaj kev ua haujlwm ruaj khov.

(2) Cov khoom tseem ceeb:

Foob rings:Pressureless sintered silicon carbide khoom feem ntau yog siv los tsim cov khoom hnav-resistant thiab corrosion-resistant sealing rings thiab zawv zawg bearings. cov

Mechanical qhov chaw:Xws li kub-kub bearings, mechanical seals, nozzles, pneumatic li qub, twj tso kua mis lub cev, fixtures, thiab lwm yam.

Cov khoom siv tshuaj:Siv los tsim cov kav dej corrosion-resistant, cia tank, reactors thiab seals. cov

Cov khoom siv hluav taws xob:Hauv kev lag luam hluav taws xob, lub zog tsis muaj zog sintered silicon carbide yog siv los tsim cov khoom kub-kub, hluav taws xob cua sov cov ntsiab lus thiab cov hloov hluav taws xob siab. cov

Kiln rooj tog:Xws li cov khoom siv thauj khoom, cov menyuam, cov nplaim taws, cov kav dej txias, thiab lwm yam hauv cov qhov cub, shuttle kilns thiab lwm yam kev lag luam kilns. cov

Cov duab ntxaws

Silicon Carbide Foob Ring

Silicon Carbide Tube

Silicon Carbide Liners

Silicon Carbide Beam

Silicon Carbide phaj

Silicon Carbide Sib Tsoo Barrel

Product Index

| SSIC cov khoom | ||

| Yam khoom | Chav tsev | Kev tshwm sim |

| Hardness | HS | ≥115 |

| Porosity tus nqi | % | <0.2 |

| Qhov ntom | g/cm3 | ≥3.10 |

| Compressive zog | Mpa | ≥2500 |

| Khoov zog | Mpa | ≥380 |

| Coefficient ntawm Expansion | 10-6 ℃ | 4.2 |

| Cov ntsiab lus ntawm SiC | % | ≥98 |

| Dawb Si | % | <1 |

| Elastic Modulus | Gpa | ≥410 |

| Max kub ntawm daim ntawv thov | ℃ | 1400 |

3. Recrystallized silicon carbide khoom (RSiC khoom)

Recrystallized Silicon Carbide Cov khoom yog cov khoom siv refractory ua los ntawm high-purity silicon carbide ua raw khoom. Nws lub ntsiab feature yog tias tsis muaj theem ob thiab nws yog tsim los ntawm 100% α-SiC .

(1) Cov yam ntxwv:

High hardness:Nws hardness yog thib ob tsuas yog pob zeb diamond, thiab nws muaj lub zog zoo heev thiab rigidity. cov

Kub kub kuj:Nws tuaj yeem tswj kev ua haujlwm ruaj khov hauv qhov kub thiab txias thiab haum rau qhov kub ntawm 1350 ~ 1600 ℃. cov

Muaj zog corrosion kuj:Nws muaj kev tiv thaiv corrosion siab rau ntau yam kev tshaj tawm thiab tuaj yeem tswj taumechanical zog rau lub sij hawm ntev nyob rau hauv ntau yam corrosive ib puag ncig. cov

Zoo oxidation tsis kam:Nws muaj qhov zoo oxidation tsis kam thiab tuaj yeem ua haujlwm ruaj khov ntawm qhov kub thiab txias. cov

Zoo thermal shock kuj:Nws ua tau zoo nyob rau hauv ib puag ncig nrog kev hloov pauv kub ceev thiab haum rau qhov chaw thermal shock. cov

Tsis muaj shrinkage thaum sintering:Nws tsis ntsws thaum lub sij hawm sintering txheej txheem, thiab tsis muaj residual kev nyuaj siab yuav generated ua deformation los yog tawg ntawm cov khoom. Nws yog haum rau kev npaj ntawm qhov chaw nrog complex duab thiab siab precision.

(2) Cov khoom tseem ceeb:

Cov khoom siv hauv tsev Kiln:Feem ntau yog siv rau cov rooj tog hauv tsev, nws muaj qhov zoo ntawm kev txuag hluav taws xob, ua kom muaj txiaj ntsig zoo ntawm qhov cub, ua kom lub voj voog luv luv, txhim kho cov khoom siv hluav taws xob thiab cov txiaj ntsig kev lag luam siab. cov

Bunner nozzles:Nws tuaj yeem siv los ua combustion nozzle hau thiab tsim nyog rau qhov kub thiab txias. cov

Ceramic radiation cua sov tubes:Cov raj cua sov no siv qhov zoo ntawm qhov kub thiab txias thiab kev tiv thaiv corrosion ntawm recrystallized silicon carbide thiab tsim nyog rau ntau yam kev siv kub kub. cov

Cov khoom tiv thaiv tubes:Tshwj xeeb tshaj yog nyob rau hauv huab cua furnaces, recrystallized silicon carbide khoom yog siv raws li tivthaiv cov hlab ntsha nrog zoo kub thiab corrosion kuj. cov

High kub twj tso kua mis lub cev, twj impellers, bearings, cav vaj tse:Nyob rau hauv lub teb ntawm tsheb, aerospace thiab tub rog industries, recrystallized silicon carbide cov ntaub ntawv yog tsim rau hauv siab kub twj tso kua mis lub cev, twj impellers, bearings thiab cav vaj tse, thiab lwm yam., noj kom zoo dua ntawm lawv kub tsis kam, acid thiab alkali corrosion kuj thiab hnav tsis kam. cov

Cov duab ntxaws

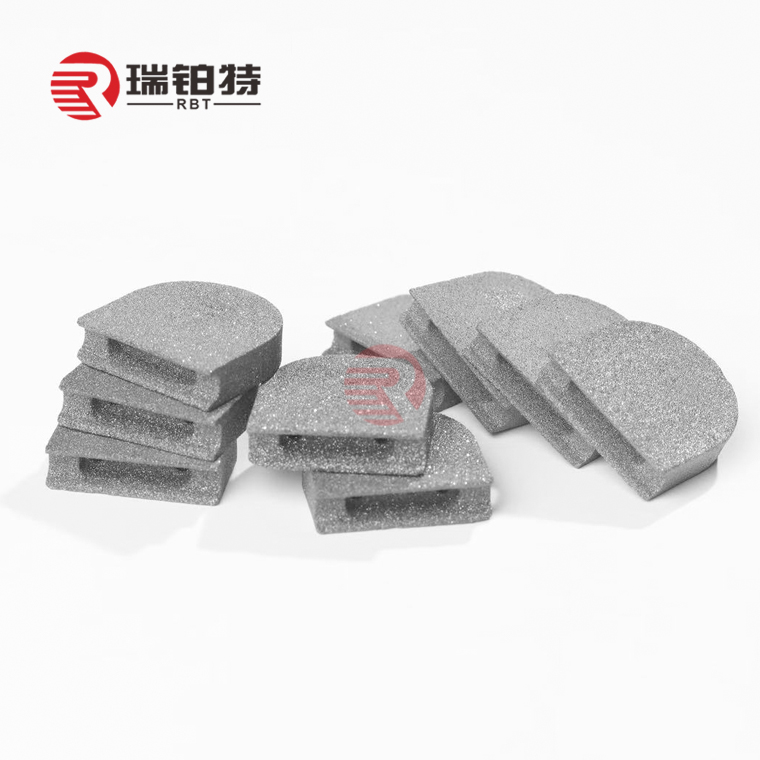

Silicon Carbide Shaped Parts

Silicon Carbide phaj

Silicon Carbide cov menyuam

Silicon Carbide Beam

Silicon Carbide Protection Tubes

Kiln Rooj tog

Silicon Carbide Sagger

Silicon Carbide Crucible

Silicon Carbide phaj

Silicon Carbide Lgniter

Silicon Carbide Tube

Silicon Carbide Burner

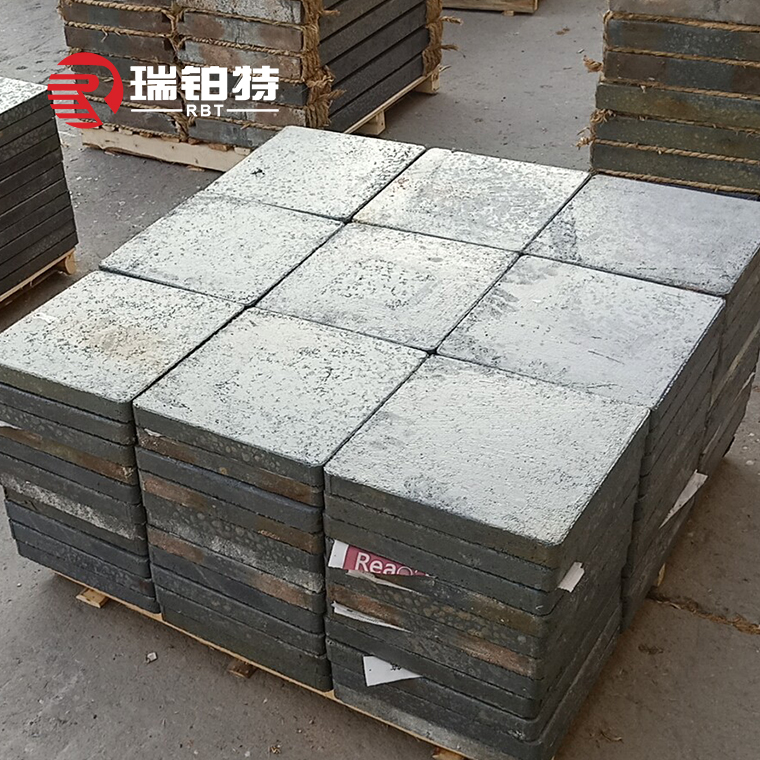

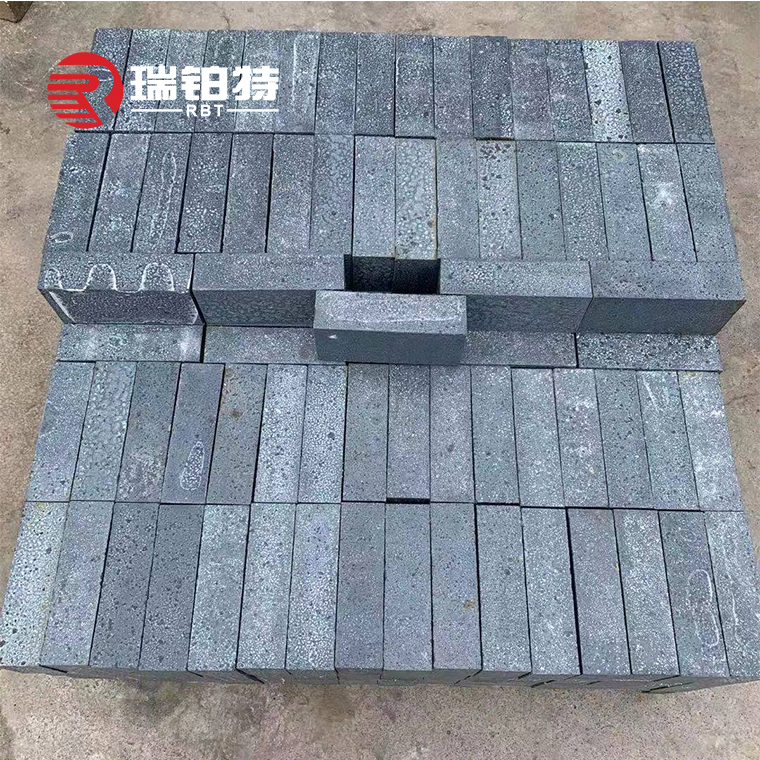

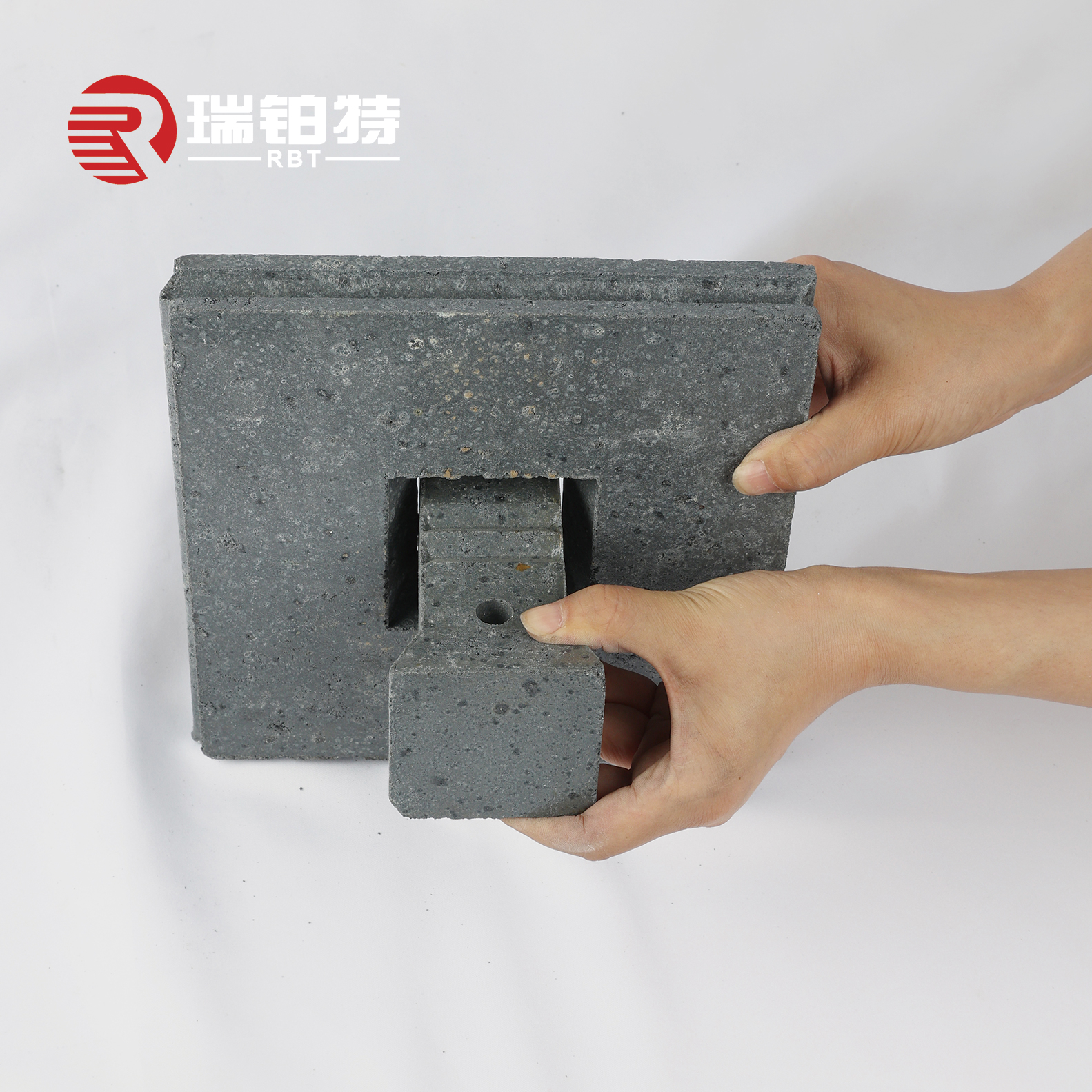

4. Silicon nitride bonded silicon carbide khoom (NSiC khoom)

Silicon nitride bonded silicon carbide cov khoom yog ib yam khoom tsim los ntawm kev ntxiv SiC aggregate rau industrial silicon hmoov, reacting nrog nitrogen ntawm kub kub los tsim Si3N4 thiab nruj combining nrog SiC hais.

(1) Cov yam ntxwv:

High hardness:Mohs hardness ntawm silicon nitride bonded silicon carbide cov khoom yog hais txog 9, thib ob tsuas yog pob zeb diamond, thiab yog cov khoom uas muaj hardness siab dua ntawm cov ntaub ntawv uas tsis yog hlau. cov

High kub lub zog:Ntawm qhov kub thiab txias ntawm 1200-1400 ℃, lub zog thiab hardness ntawm cov khoom tseem yuav luag tsis hloov, thiab qhov siab tshaj plaws kev nyab xeeb siv kub tuaj yeem ncav cuag 1650-1750 ℃.

cov

Thermal stability:Nws muaj ib qho me me thermal expansion coefficient thiab siab thermal conductivity, tsis yooj yim los tsim thermal stress, muaj thermal shock stability thiab creep resistance, thiab yog haum rau qhov chaw txias thiab kub. cov

Chemical stability:Nws yog corrosion-resistant thiab oxidation-resistant, thiab tuaj yeem nyob ruaj khov hauv ntau qhov chaw tshuaj lom neeg. cov

Hnav tsis kam:Nws muaj qhov hnav tsis zoo thiab tsim nyog rau ntau yam kev lag luam nrog kev hnav hnyav.

(2) Cov khoom tseem ceeb:

Refractory bricks:dav siv nyob rau hauv electrolytic aluminium, ironmaking blast furnaces, submerged arc furnaces thiab lwm yam lag luam, nrog rau cov yam ntxwv ntawm kub tsis kam, corrosion kuj, thiab yaig kuj.

Kiln rooj tog:siv rau ceramic sib tsoo log, high-voltage hluav taws xob porcelain, muaj kilns, thiab lwm yam., nrog zoo load-bearing muaj peev xwm thiab siab kub kuj.

Cov khoom tshwj xeeb zoo li:siv nyob rau hauv non-ferrous metallurgical casting, thermal zog, submerged arc furnaces thiab lwm yam lag luam, nrog rau cov yam ntxwv ntawm hnav tsis kam thiab kub tsis kam.

Refractory qhov chaw:nrog rau cov thermocouple tiv thaiv tubs, riser tubes, lub tes tsho cua sov, thiab lwm yam., siv nyob rau hauv high-temperature kilns thiab ntau yam cua, nrog siab thermal conductivity thiab corrosion kuj.

Cov duab ntxaws

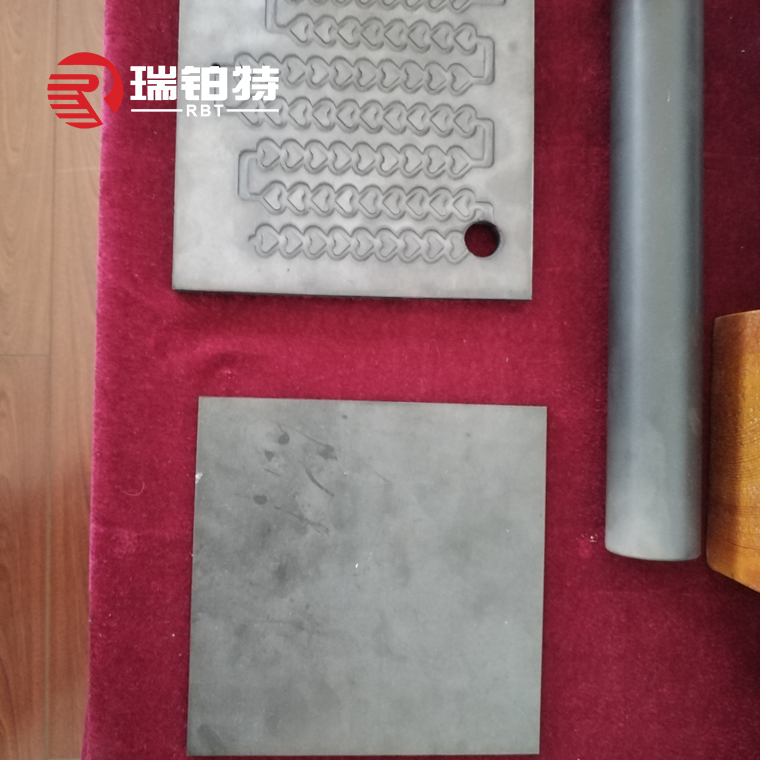

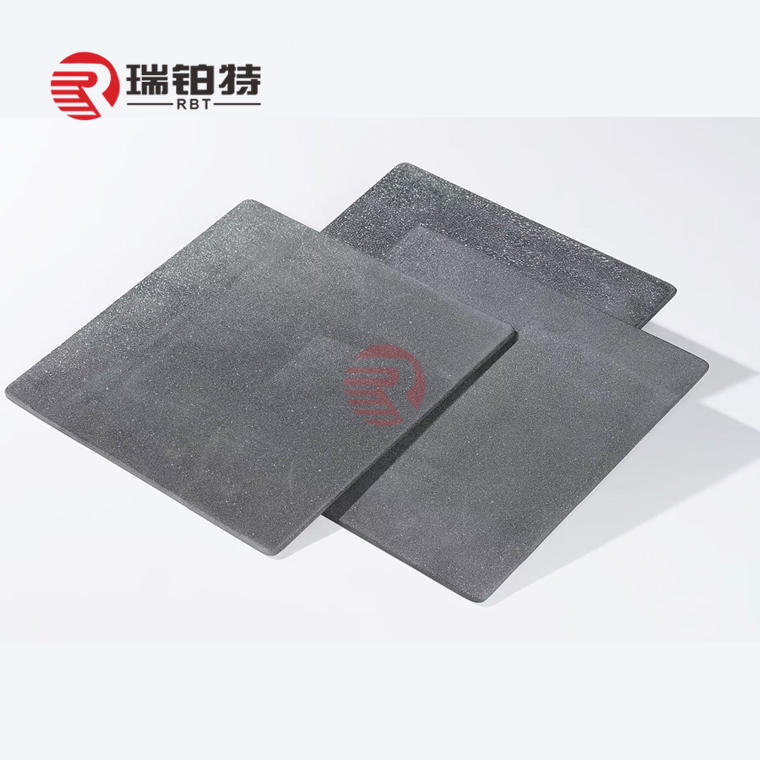

Silicon Carbide Plate

Silicon Carbide Plate

Silicon Carbide Plate

Silicon Carbide Plate

Silicon Carbide Plate

Silicon Carbide Radiation Tubes

Silicon Carbide Tube

Silicon Carbide Plate

Silicon Carbide Shaped Parts

Silicon Carbide Protection Tubes

Silicon Carbide phaj

Silicon Carbide Cib

5. Oxide-bonded silicon carbide khoom

Oxide-bonded silicon carbide khoom yog tsim los ntawm kev sib xyaw silicon carbide hais nrog oxide hmoov (xws li silicon dioxide los yog mullite), nias thiab sintering ntawm qhov kub thiab txias. Nws cov yam ntxwv yog tias thaum lub sij hawm sintering thiab siv cov txheej txheem, cov oxide zaj duab xis yog qhwv rau ntawm silicon carbide hais, uas ho txhim kho oxidation tsis kam thiab kub lub zog.

Nws muaj cov yam ntxwv ntawm qhov kub thiab txias flexural lub zog, zoo thermal shock stability, siab thermal conductivity, hnav tsis kam thiab muaj zog tiv thaiv rau ntau yam cua yaig, thiab yog ib qho zoo tagnrho lub zog-txuag khoom rau industrial furnaces.

(2) Cov khoom tseem ceeb:

Silicon dioxide bonded silicon carbide khoom:Cov khoom no siv silicon dioxide (SiO2) raws li lub sijhawm khi. Feem ntau 5% ~ 10% ntawm silicon dioxide hmoov los yog quartz hmoov yog tov nrog silicon carbide (SiC) hais. Qee zaum ib qho flux ntxiv. Tom qab nias thiab sib sau, nws raug rho tawm haujlwm nyob rau hauv lub qhov cub dav dav. Nws cov yam ntxwv yog tias thaum lub sij hawm tua thiab siv cov txheej txheem, silicon dioxide zaj duab xis yog qhwv rau ntawm silicon carbide hais, uas ho txhim kho oxidation tsis kam thiab kub siab zog. Cov khoom no yog dav siv nyob rau hauv kiln txee rau firing porcelain (> 1300 ℃), thiab nws cov kev pab cuam lub neej yog ntau tshaj.

ob npaug ntawm cov av nplaum-bonded silicon carbide khoom. cov

Mullite bonded silicon carbide khoom:Cov khoom no ntxiv α-Al2O3 hmoov thiab silicon dioxide hmoov rau cov khoom xyaw silicon carbide. Tom qab nias thiab sib sau, Al2O3 thiab SiO2 tau muab tso ua ke los tsim mullite thaum lub sijhawm sintering. Thaum siv, silicon dioxide tsim los ntawm oxidation ntawm silicon carbide ib feem ntawm mullite nrog Al2O3. Cov khoom no muaj qhov zoo thermal shock stability thiab yog siv dav hauv kev tsim cov porcelain saggers thiab txee.

Cov duab ntxaws

Silicon Carbide phaj

Silicon Carbide Cib

Silicon Carbide phaj

SiC Microcrystalline yeeb nkab

SiC Microcrystalline Board

SiC Microcrystalline Board

Tuam txhab Profile

Shandong Robert Tshiab Khoom Co., Ltd.yog nyob rau hauv Zibo City, Shandong xeev, Suav teb, uas yog ib tug refractory cov ntaub ntawv ntau lawm puag. Peb yog ib lub tuam txhab niaj hnub uas koom nrog kev tshawb fawb thiab kev tsim kho, kev tsim khoom, muag, kiln tsim thiab kev tsim kho, thev naus laus zis, thiab xa tawm cov ntaub ntawv refractory. Peb muaj cov cuab yeej ua tiav, cov thev naus laus zis siab heev, muaj zog technical, cov khoom zoo heev, thiab lub koob npe zoo. Peb lub Hoobkas npog ntau tshaj 200 daim av thiab cov khoom tsim tawm txhua xyoo ntawm cov khoom siv refractory yog kwv yees li 30000 tons thiab cov ntaub ntawv tsis zoo yog 12000 tons.

Peb cov khoom tseem ceeb ntawm cov ntaub ntawv refractory muaj xws li:alkaline refractory khoom; aluminium silicon refractory cov ntaub ntawv; unshaped refractory khoom; rwb thaiv tsev thermal refractory cov ntaub ntawv; cov ntaub ntawv tshwj xeeb refractory; functional refractory cov ntaub ntawv rau nruam casting tshuab.

Cov lus nug nquag

Xav tau kev pab? Nco ntsoov mus saib peb lub rooj sab laj kev txhawb nqa rau cov lus teb rau koj cov lus nug!

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov ntaub ntawv refractory rau ntau tshaj 30 xyoo. Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov zoo tshaj plaws ua ntej muag thiab kev pab cuam tom qab muag.

Rau txhua tus txheej txheem tsim khoom, RBT muaj kev ua tiav QC rau cov tshuaj muaj pes tsawg leeg thiab lub cev muaj zog. Thiab peb yuav kuaj cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom. Yog tias koj muaj cov cai tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws kom haum lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv. Tab sis peb cog lus tias yuav nkoj sai li sai tau nrog lav zoo.

Tau kawg, peb muab cov qauv dawb.

Yog lawm, tau kawg, txais tos tuaj xyuas RBT tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov ntaub ntawv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb zog thiab kev nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov kilns sib txawv thiab muab kev pabcuam ib zaug.