RSiC Tiv Thaiv Raj

Cov Ntaub Ntawv Khoom

Silicon carbide Tiv Thaiv Cov Rajyog cov khoom siv tshwj xeeb tubular ua los ntawm silicon carbide (SiC) cov khoom siv ceramic, feem ntau yog siv los tiv thaiv cov khoom rhiab heev (xws li thermocouples) lossis ua cov khoom tseem ceeb hauv kev thauj mus los kua dej kub thiab cov khoom siv pauv cua sov.

Peb cov khoom feem ntau yog tsim los ntawm kev siv peb txoj kev:Kev sib xyaw ua ke ntawm cov tshuaj tiv thaiv (RBSiC), Kev sib xyaw ua ke ntawm cov tshuaj silicon carbide (NSiC)

1. Cov raj tiv thaiv RSiC

Siv cov hmoov SiC micro uas muaj cov khoom siv siab purity ua cov khoom siv raw, nws raug sintered ntawm qhov kub siab (2000–2200 ℃). Ib qho qauv ntom ntom yog tsim los ntawm kev recrystallization thiab cov ciam teb ntawm cov khoom SiC lawv tus kheej, tsis muaj theem txuas ntxiv.

Cov Yam Ntxwv Tseem Ceeb:

Kev Tiv Thaiv Kub Siab Tshaj Plaws:Kev ua haujlwm kub ntev txog li 1600 ℃, lub sijhawm luv luv txog 1800 ℃, ua rau nws zoo tshaj plaws hauv kev tiv thaiv kub siab ntawm peb hom, tsim nyog rau cov kilns kub siab heev (xws li cov kilns ceramic sintering thiab cov cub tawg metallurgical).

Kev Tiv Thaiv Oxidation Zoo heev:Thaum kub siab, ib daim zaj duab xis tiv thaiv SiO₂ ntom ntom tsim rau ntawm qhov chaw, tiv thaiv kev oxidation ntxiv ntawm SiC sab hauv, qhia txog kev ruaj khov siab heev hauv cov huab cua oxidizing.

Qhov Coefficient ntawm Thermal Expansion qis heev:Tus coefficient ntawm thermal expansion tsuas yog 4.5 × 10⁻⁶ /℃, muab kev tiv thaiv thermal zoo, txawm hais tias qis dua me ntsis ntawm silicon nitride-bonded silicon carbide.

Kev nyuaj siab thiab kev hnav tsis kam siab:Nrog Mohs hardness ze rau 9, nws ua rau pom kev tiv taus cov khoom siv yaig thiab kev puas tsuaj, ua rau nws haum rau cov huab cua kub thiab cov kua dej ntws uas muaj cov khoom khov.

Kev ruaj khov tshuaj lom neeg muaj zog:Tiv taus cov kua qaub thiab alkalis muaj zog, thiab tsis cuam tshuam nrog feem ntau cov hlau uas yaj.

Cov Kev Txwv:

Qhov kub sintering siab heev, ua rau muaj porosity siab me ntsis (kwv yees li 5% -8%) thiab tsis muaj zog me ntsis ntawm kev tiv thaiv siab; qhov brittleness ntawm chav tsev kub siab, thiab kev tiv thaiv kev cuam tshuam tsis zoo li silicon nitride-bonded silicon carbide.

2. RBSiC tiv thaiv raj

Siv cov khoom me me SiC thiab graphite ua cov khoom siv raw, cov khoom siv no dhau los ntawm cov txheej txheem infiltration silicon. Cov kua silicon nkag mus rau hauv thiab puv cov qhov hws, ua rau cov graphite ua rau SiC theem tshiab, thiab thaum kawg tsim cov qauv sib xyaw ua ke ntawm "SiC framework + free silicon".

Cov Yam Ntxwv Tseem Ceeb:

Qhov ceev ceev thiab porosity tsawg:Silicon dawb puv cov qhov hws, txo qhov porosity kom qis dua 1%, ua rau muaj huab cua zoo heev thiab tiv taus siab, tsim nyog rau siab thiab kub.

cov xwm txheej sealing (xws li lub cub tawg sintering siab).

Cov khoom siv kho tshuab zoo:Lub zog khoov ntawm chav tsev kub yog 250–400MPa, qhov tawg tawg siab, thiab kev cuam tshuam tsis zoo dua li recrystallized silicon carbide.

Kev tiv thaiv kub nruab nrab:Qhov kub ua haujlwm ntev yog 1200 ℃. Saum toj no 1350 ℃, cov silicon dawb mos, ua rau lub zog txo qis thiab txwv kev ua haujlwm kub siab.

Kev ua tau zoo:Qhov muaj cov silicon dawb txo qhov brittleness ntawm cov khoom, ua rau nws yooj yim rau kev tshuab ua cov duab nyuaj, ua rau cov nqi tsim khoom qis dua.

Cov Kev Txwv:

Kev ua haujlwm kub siab yog txwv los ntawm silicon dawb, ua rau nws tsis haum rau kev ua haujlwm ntev tshaj 1350 ℃; silicon dawb yooj yim reacts nrog cov alkalis muaj zog, txhuas molten, thiab lwm yam, ua rau muaj qhov ntau ntawm kev tiv thaiv corrosion nqaim.

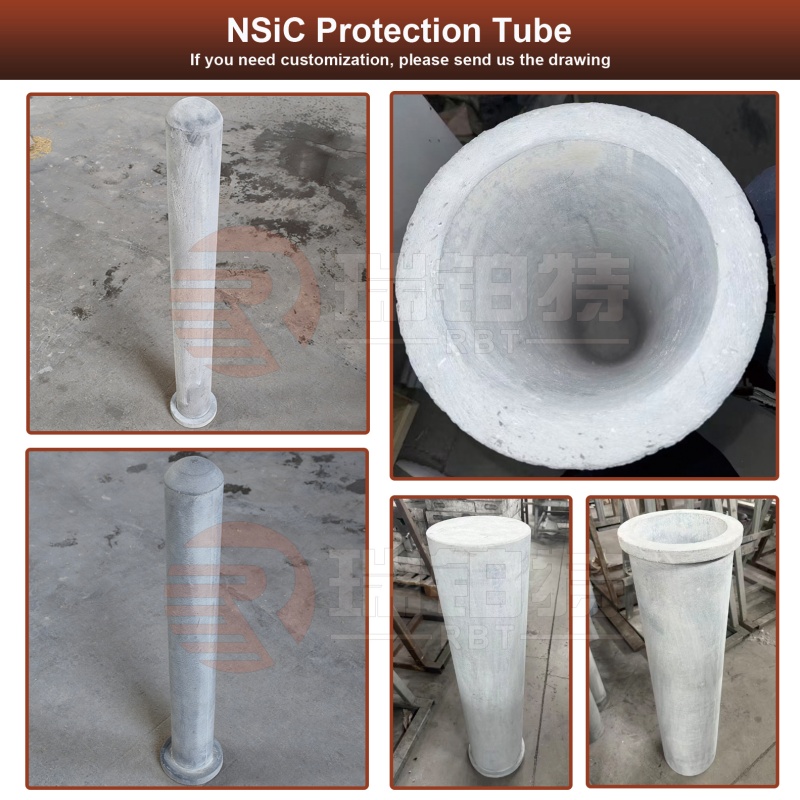

3. NSiC tiv thaiv raj

Nws yog cov khoom sib xyaw ua ke uas tsim los ntawm kev sib txuas SiC cov khoom me me hauv silicon carbide matrix los ntawm kev tsim Si₃N₄ ua theem khi los ntawm kev sib xyaw nitriding.

Cov Nta Tseem Ceeb:

1. Kev Tiv Thaiv Kev Poob Siab Thermal Siab Heev:Qhov coefficient qis ntawm thermal expansion thiab siab toughness ntawm Si₃N₄ bonded theem tso cai rau lub raj tiv thaiv kom tiv taus cua sov thiab txias sai tshaj 1000 ℃ yam tsis muaj kev tawg vim muaj kev hloov pauv kub sai, ua rau nws haum rau kev ua haujlwm nrog kev hloov pauv kub ntau zaus.

2. Kev Tiv Thaiv Kev Xeb Zoo heev:Ruaj khov heev tiv thaiv cov kua qaub muaj zog, cov alkali muaj zog, cov hlau molten (xws li txhuas thiab tooj liab), thiab cov ntsev molten, ua rau nws tsim nyog rau cov chaw corrosive hauv kev lag luam tshuaj lom neeg thiab hlau.

3. Lub Zog Kho Tshuab Siab:Lub zog khoov ntawm chav tsev kub txog 300–500 MPa, nrog rau kev khaws cia lub zog zoo dua ntawm qhov kub siab dua li cov khoom SiC ntshiab, thiab kev tiv taus kev cuam tshuam muaj zog.

4. Kub Ua Haujlwm:Kev ua haujlwm kub ntev 1350 ℃, lub sijhawm luv luv tuaj yeem tiv taus txog li 1500 ℃.

5. Kev Rwb Thaiv Zoo:Tswj tau qhov rwb thaiv hluav taws xob zoo txawm tias nyob rau hauv qhov kub siab, tiv thaiv kev cuam tshuam ntawm cov teeb liab thermocouple.

Cov Kev Txwv:

Kev tsis kam ntawm oxidation yog me ntsis qis dua li recrystallized silicon carbide; kev siv mus sij hawm ntev hauv cov huab cua oxidizing muaj zog yuav ua rau cov txheej oxide saum npoo av tev tawm.

Cov Nta Tseem Ceeb Sib Piv Rooj

| Yam ntxwv | Si₃N₄-SiC | R-SiC | RB-SiC |

| Kub Ua Haujlwm Ntev | 1350 ℃ | 1600 ℃ | 1200 ℃ |

| Kev Tiv Thaiv Kev Kub Ntxhov | Zoo tshaj plaws | Zoo | Nruab Nrab |

| Cov Khoom Siv Antioxidant | Zoo | Zoo tshaj plaws | Nruab Nrab |

| Kev Tiv Thaiv Kev Xeb | Muaj zog (tiv taus cov kua qaub thiab alkalis / hlau yaj) | Muaj zog (tiv taus oxidation thiab corrosion) | Nruab Nrab (Tsis txhob siv cov alkalis muaj zog/aluminium yaj) |

| Qhov porosity | 3%–5% | 5%–8% | <1% |

| Kev Tiv Thaiv Kev Cuam Tshuam | Muaj zog heev | Tsis muaj zog | Nruab Nrab |

Cov Lag Luam thiab Cov Xwm Txheej Ib Txwm Muaj

1. NSiC thermocouple tiv thaiv raj

Kev Lag Luam Tshuaj:Kev ntsuas kub hauv cov hlab ntsha acid-base, cov hlwb electrolytic ntsev molten, thiab cov tank cia khoom nruab nrab corrosive; tiv taus kev xeb mus sij hawm ntev los ntawm cov kua qaub muaj zog, alkalis, thiab ntsev molten; tsim nyog rau cov xwm txheej tshuaj tiv thaiv tsis tu ncua nrog kev hloov pauv kub ntau zaus.

Kev Lag Luam Hlau:Kev ntsuas kub ntawm cov hlau yaj hauv cov pwm txhuas tuag-casting, cov cub tawg tooj liab, thiab cov cub tawg hlau uas tsis yog ferrous; tiv taus kev yaig hlau yaj, thiab nws cov rwb thaiv tsev kub siab zam kev cuam tshuam ntawm cov teeb liab thermocouple.

Kev Lag Luam Khoom Siv Hauv Tsev:Kev ntsuas kub hauv cov qhov cub ua kom sov thiab cov qhov cub gypsum calcining; muaj peev xwm tiv taus cua sov thiab txias sai los ntawm kev pib thiab kaw qhov cub; tiv taus xeb los ntawm cov roj alkaline flue hauv qhov cub.

2. Cov raj tiv thaiv RSiC Thermocouple

Kev Lag Luam Khoom Siv Hauv Tsev:Kev ntsuas kub hauv cov chaw hlawv cement rotary kiln, ceramic roller kilns, thiab refractory material tunnel kilns; tiv taus qhov kub siab heev ntawm 1600 ℃ thiab kev yaig muaj zog los ntawm cov hmoov kub siab, tsim nyog rau cov xwm txheej tsim khoom kub siab tas mus li.

Kev Lag Luam Hlau:Kev ntsuas kub hauv cov kav dej kub ntawm lub cub tawg, cov hlau molten, thiab cov khoom siv ua ntej molten; tuaj yeem siv tau ntev hauv cov huab cua oxidizing muaj zog, tiv taus xeb los ntawm cov pa roj flue kub thiab hlau slag.

Kev Lag Luam Iav:Kev ntsuas kub hauv cov tshuab ua kom iav yaj thiab cov pwm tsim iav; tiv taus qhov kub siab corrosion thiab erosion los ntawm cov iav molten, ua tau raws li qhov xav tau kub siab tas mus li ntawm kev tsim iav.

3. RBSiC Thermocouple Tiv Thaiv Cov Hlab

Kev Lag Luam Tsim Khoom Siv Tshuab:Kev ntsuas kub hauv cov cub tawg kho cua sov, cov cub tawg uas siv roj quenching, thiab cov cub tawg carburizing; tsim nyog rau cov xwm txheej kub nruab nrab thiab qis, thiab tuaj yeem tiv taus qhov kev puas tsuaj me me hauv qhov cub tawg.

Kev Lag Luam Fais Fab:Kev ntsuas kub rau cov boilers siab atmospheric, cov qhov cub kub tawg, thiab cov khoom siv rov qab cua sov pov tseg; tsim nyog rau cov huab cua nruab nrab lossis oxidizing tsis muaj zog, ua tau raws li qhov yuav tsum tau ntsuas kub kaw los ntawm qis mus rau nruab nrab-siab siab.

Cov Khoom Siv Sim:Kev ntsuas kub rau cov cub tawg me me uas muaj siab siab thiab cov cub tawg tubular hauv chav kuaj; nws cov porosity qis thiab airtightness ua rau nws haum rau qhov chaw me me, qhov chaw siab kaw kev sim.

Kev lag luam hlau

Tshuaj lom neeg

Lub zog

Kev tsav dav hlau

Hluav taws xob

Cov Kilns Rau Cov Menyuam

Cov Ntaub Ntawv Txog Lub Tuam Txhab

Shandong Robert New Material Co., Ltd.nyob hauv Zibo City, Shandong xeev, Suav teb, uas yog lub hauv paus tsim cov khoom siv refractory. Peb yog ib lub tuam txhab niaj hnub uas koom ua ke kev tshawb fawb thiab kev txhim kho, kev tsim khoom, kev muag khoom, kev tsim kho qhov cub, thev naus laus zis, thiab kev xa tawm cov khoom siv refractory. Peb muaj cov khoom siv tiav, thev naus laus zis siab heev, lub zog muaj zog, cov khoom zoo heev, thiab lub koob npe zoo. Peb lub Hoobkas npog ntau dua 200 daim av thiab cov khoom tsim tawm txhua xyoo yog kwv yees li 30000 tons thiab cov khoom siv refractory tsis muaj duab yog 12000 tons.

Peb cov khoom tseem ceeb ntawm cov ntaub ntawv refractory suav nrog:Cov ntaub ntawv alkaline refractory; cov ntaub ntawv aluminium silicon refractory; cov ntaub ntawv refractory tsis muaj duab; cov ntaub ntawv thermal refractory rwb thaiv tsev; cov ntaub ntawv refractory tshwj xeeb; cov ntaub ntawv refractory ua haujlwm rau cov txheej txheem casting tas mus li.

Cov Lus Nug Feem Ntau

Xav tau kev pab? Nco ntsoov mus saib peb cov rooj sib tham txhawb nqa kom tau cov lus teb rau koj cov lus nug!

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov khoom siv refractory rau ntau tshaj 30 xyoo. Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov kev pabcuam ua ntej muag thiab tom qab muag zoo tshaj plaws.

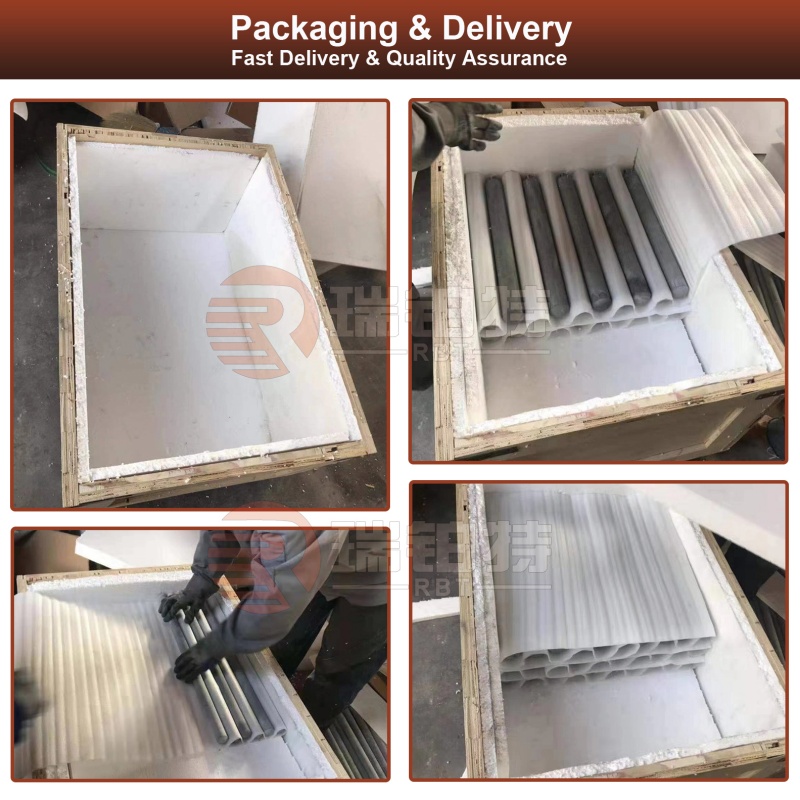

Rau txhua txoj kev tsim khoom, RBT muaj lub kaw lus QC tiav rau cov tshuaj lom neeg thiab cov khoom siv lub cev. Thiab peb yuav sim cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom. Yog tias koj muaj cov kev xav tau tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws los pab txhawb lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv. Tab sis peb cog lus tias yuav xa khoom sai li sai tau nrog kev lees paub zoo.

Tau kawg, peb muab cov qauv dawb.

Yog, tau kawg, koj tuaj yeem mus xyuas RBT lub tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov khoom siv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb nqa kev txawj ntse thiab kev paub nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov cub tawg sib txawv thiab muab kev pabcuam ib zaug.