Cov khoom siv refractory

Kev piav qhia txog khoom

Cov khoom siv refractoryyog cov khoom sib xyaw ua ke ntawm cov khoom siv refractory, hmoov thiab cov khoom khi. Tom qab ntxiv dej lossis lwm yam kua, lawv tsim nyog rau kev tsim kho los ntawm kev nchuav thiab kev co. Lawv kuj tuaj yeem ua prefabricated rau hauv cov khoom prefabricated nrog cov duab thiab qhov ntau thiab tsawg tshwj xeeb rau kev tsim kho ntawm cov khoom siv cua sov industrial. Txhawm rau txhim kho cov khoom siv lub cev thiab tshuaj lom neeg thiab kev ua haujlwm ntawm cov khoom siv refractory castables, cov khoom sib xyaw kom haum feem ntau ntxiv, xws li cov yas, cov khoom tawg, cov khoom ua kom nrawm, cov khoom ncua, cov neeg sawv cev nthuav dav, cov neeg sawv cev debonding-gelling, thiab lwm yam. Tsis tas li ntawd, rau cov khoom siv refractory castables siv rau hauv thaj chaw uas muaj zog loj lossis muaj zog thermal shock, yog tias ntxiv cov hlau tsis xeb fiber ntau, qhov tawv ntawm cov khoom yuav nce ntxiv ntau. Hauv cov khoom siv insulating refractory castable, yog tias ntxiv cov inorganic fibers, nws tsis tsuas yog txhim kho qhov tawv, tab sis kuj pab txhim kho nws cov khoom siv thermal rwb thaiv tsev. Txij li thaum cov khoom siv yooj yim ntawm cov refractory castables (xws li aggregates thiab hmoov, admixtures, binders thiab admixtures), coagulation thiab hardening txheej txheem, kev tsim kho, thiab lwm yam, zoo ib yam li cov pob zeb hauv kev tsim kho vaj tse, nws tau raug hu uacov pob zeb ua kom tsis kub.

Cov Khoom Muag

| Lub Npe Khoom | Kev Sib Tw Uas Yooj Yim | ||||||

| Kev Txwv Kub Ua Haujlwm | 1100 | 1200 | 1400 | 1500 xyoo | 1600 xyoo | ||

| 110 ℃ Qhov Ceev Ntau (g / cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulus ntawm Rupture (MPa) ≥ | 110 ℃ × 24 teev | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100 ℃ × 3 teev | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400 ℃ × 3 teev | ― | ― | 3 | 10.8 | 8.1 | ||

| Lub zog tsoo txias (MPa) ≥ | 110 ℃ × 24 teev | 8 | 8 | 11 | 12 | 10 | |

| 1100 ℃ × 3 teev | 4 | 4 | 5 | 11 | 10 | ||

| 1400 ℃ × 3 teev | ― | ― | 15 | 22 | 14 | ||

| Kev Hloov Pauv Mus Ib Txhis (%) | 1100 ℃ × 3 teev | -0.65 1000 ℃ × 3 teev | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400 ℃ × 3 teev | ― | ― | -0.8 | -0.55 | -0.45 | ||

| Kev Ua Hluav Taws Xob (Thermal Conductivity)W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700 ℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3 (%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3 (%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

| Lub Npe Khoom | Cov Cement Uas Tsis Tshua Muaj Castable | |||||

| INDEX | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Kev Txwv Kub Ua Haujlwm | 1300 | 1350 xyoo | 1400 | 1400 | 1450 xyoo | |

| Qhov Ceev Ntau (g/cm3) 110 ℃ × 24h ≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Lub zog khoov txias 110 ℃ × 24 teev (MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Lub zog tsoo txias (MPa) ≥ | 110 ℃ × 24 teev | 25 | 30 | 35 | 35 | 40 |

| CT ℃ × 3 teev | 50 1300 ℃ × 3 teev | 55 1350 ℃ × 3 teev | 60 1400 ℃ × 3 teev | 40 1400 ℃ × 3 teev | 70 1400 ℃ × 3 teev | |

| Kev Hloov Pauv Mus Ib Txhis @CT ℃ × 3h (%) | -0.5~+0.5 1300 ℃ | -0.5~+0.5 1350 ℃ | 0~+0.8 1400 ℃ | 0~+0.8 1400 ℃ | 0~+1.0 1400 ℃ | |

| Kev Tiv Thaiv Kev Kub Ntxhov (1000 ℃ dej) ≥ | ― | ― | ― | 20 | ― | |

| Al2O3 (%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO (%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3 (%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Lub Npe Khoom | Muaj Zog Castable Siab | |||||

| INDEX | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Kev Txwv Ua Haujlwm Kub (℃) | 1400 | 1500 xyoo | 1600 xyoo | 1700 xyoo | 1800 xyoo | |

| 110 ℃ Qhov Ceev Ntau (g / cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Modulus ntawm Rupture (MPa) ≥ | 110 ℃ × 24 teev | 6 | 8 | 8 | 8.5 | 10 |

| 1100 ℃ × 3 teev | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400 ℃ × 3 teev | 8.5 1300 ℃ × 3 teev | 9 | 9.5 | 10 | 15 | |

| Lub zog tsoo txias (MPa) ≥ | 110 ℃ × 24 teev | 35 | 40 | 40 | 45 | 60 |

| 1100 ℃ × 3 teev | 40 | 50 | 45 | 50 | 70 | |

| 1400 ℃ × 3 teev | 45 1300 ℃ × 3 teev | 55 | 50 | 55 | 100 | |

| Kev Hloov Pauv Mus Ib Txhis (%) | 1100 ℃ × 3 teev | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400 ℃ × 3 teev | -0.45 1300 ℃ × 3 teev | -0.4 | -0.3 | -0.3 | -0.1 | |

| Al2O3 (%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| CaO (%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Fe2O3 (%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

Daim Ntawv Thov

1. Cov khoom siv ua los ntawm cov hlau txhuas siab:Cov khoom siv ua los ntawm cov hlau siab (high-aluminium castable) feem ntau yog ua los ntawm alumina (Al2O3) thiab muaj kev tiv taus hluav taws xob siab, tiv taus slag thiab tiv taus thermal shock. Nws yog siv dav hauv cov cub tawg kub thiab qhov cub hauv cov hlau, cov hlau tsis yog ferrous, tshuaj lom neeg thiab lwm yam lag luam.

2. Cov hlau fiber reinforced castable:Cov hlau fiber reinforced castable yog ua los ntawm cov castables ib txwm thiab ntxiv cov hlau fibers los txhim kho nws cov thermal shock tsis kam, hnav tsis kam thiab slag tsis kam. Nws yog siv rau hauv cov cub tawg, hauv qab cub tawg thiab lwm qhov chaw hauv cov hlau, metallurgy, petrochemical thiab lwm yam lag luam.

3. Mullite castable:Mullite castable feem ntau yog ua los ntawm mullite (MgO · SiO2) thiab muaj kev tiv thaiv zoo hnav, refractoriness thiab slag tsis kam. Nws feem ntau siv rau hauv cov khoom tseem ceeb xws li steelmaking furnaces thiab converters hauv hlau, metallurgy thiab lwm yam lag luam.

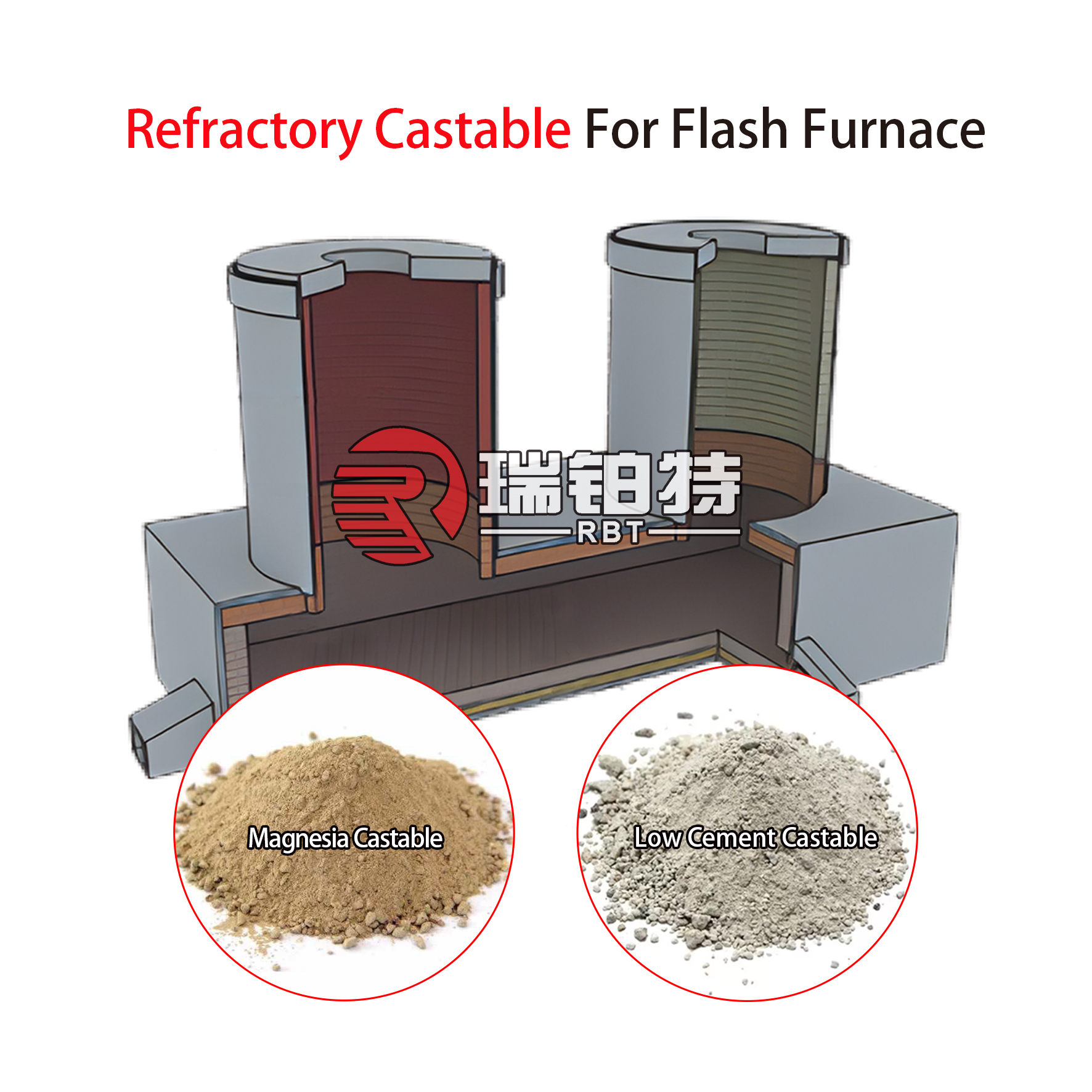

4. Silicon carbide castable:Silicon carbide castable feem ntau yog ua los ntawm silicon carbide (SiC) thiab muaj kev tiv thaiv zoo heev, tiv thaiv slag thiab thermal shock. Siv dav hauv cov cub tawg kub, cov txaj cub tawg thiab lwm qhov ntawm cov hlau tsis yog ferrous, tshuaj lom neeg, ceramics thiab lwm yam lag luam.

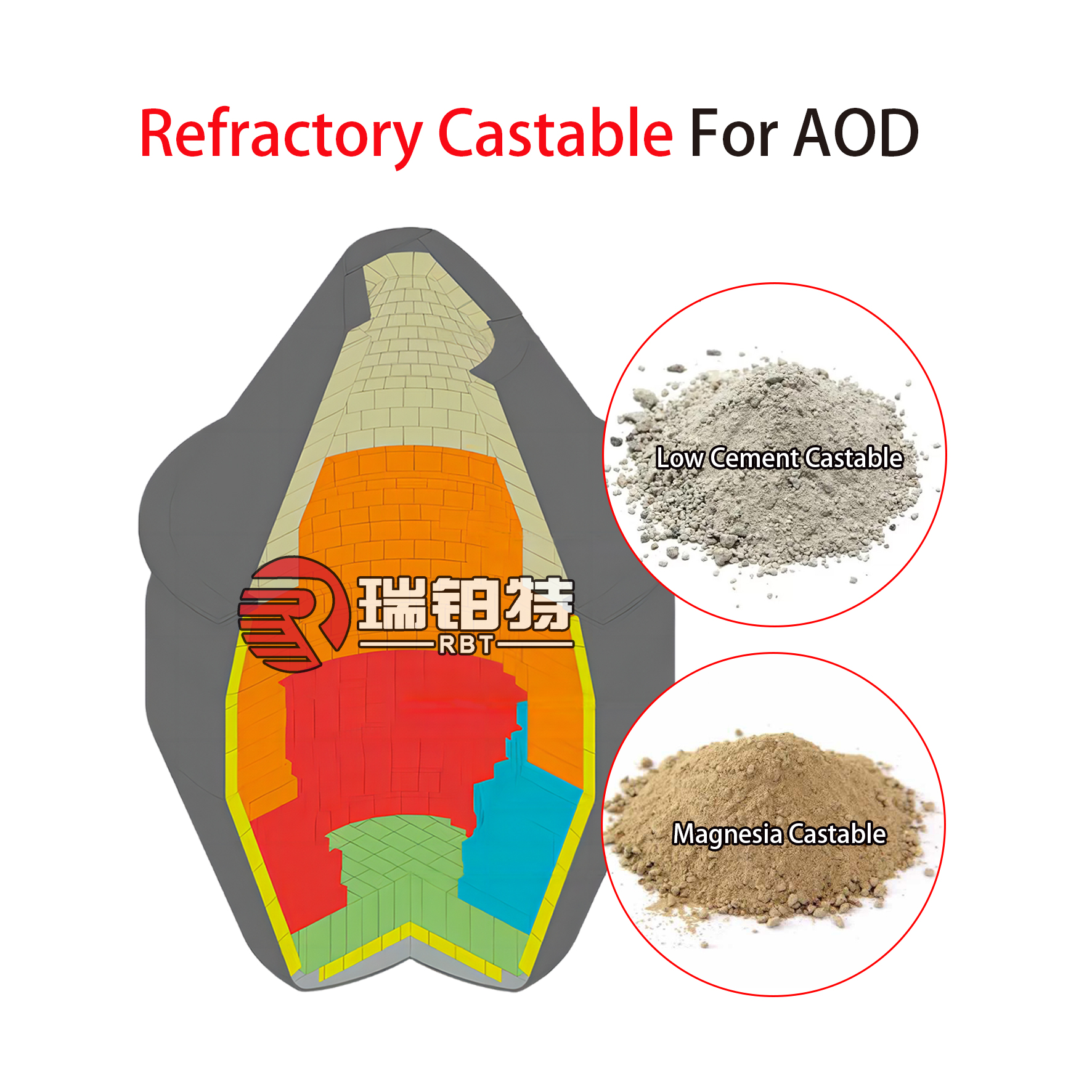

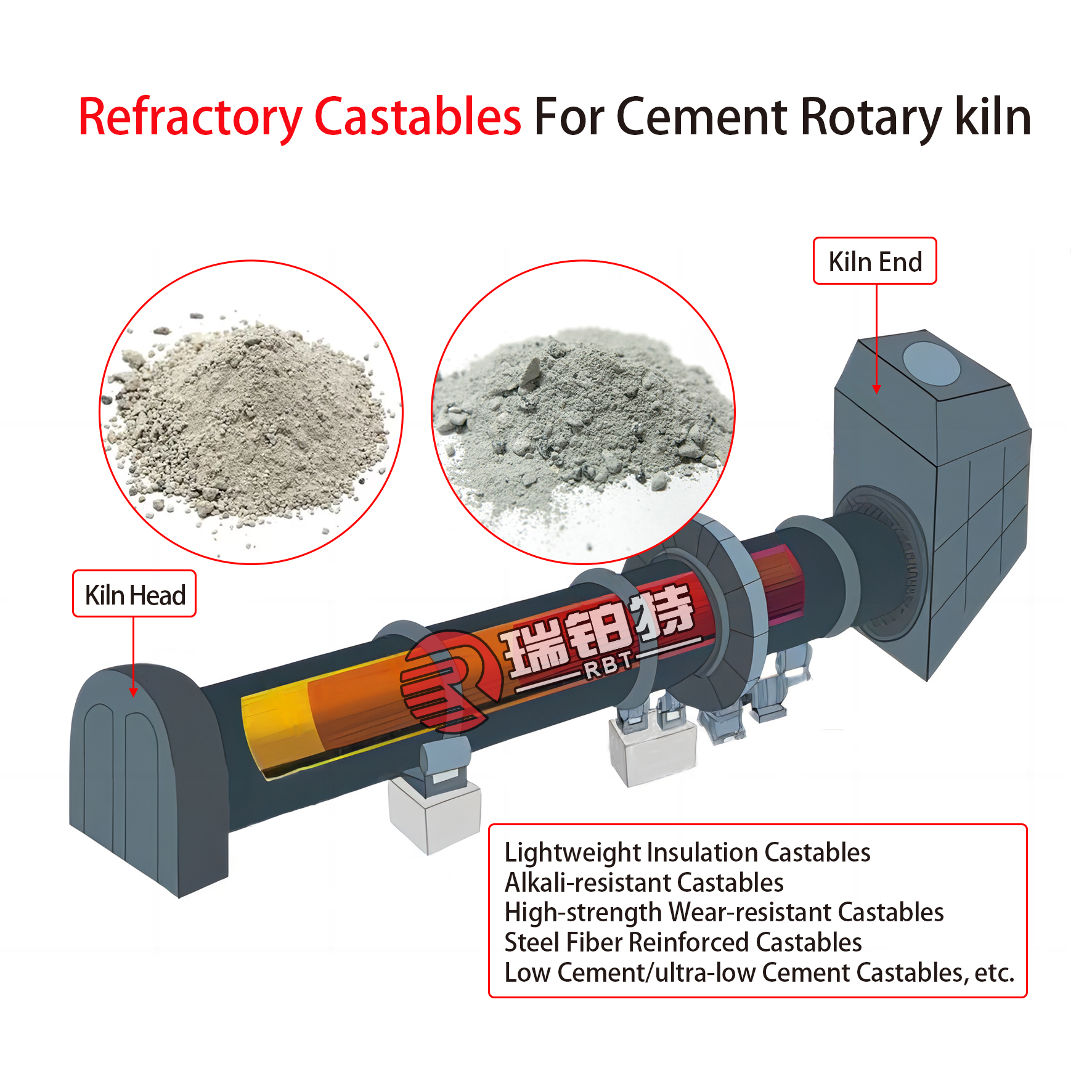

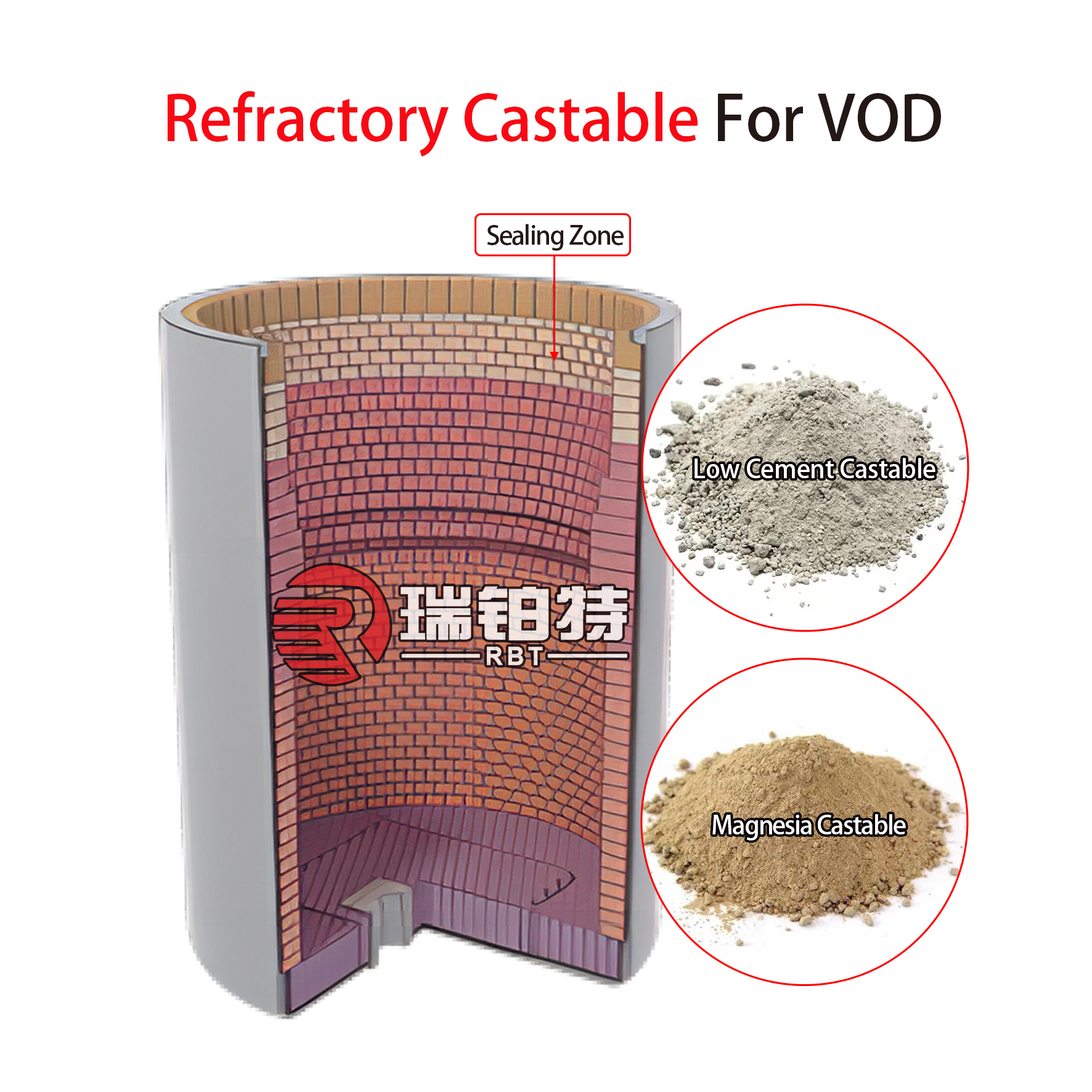

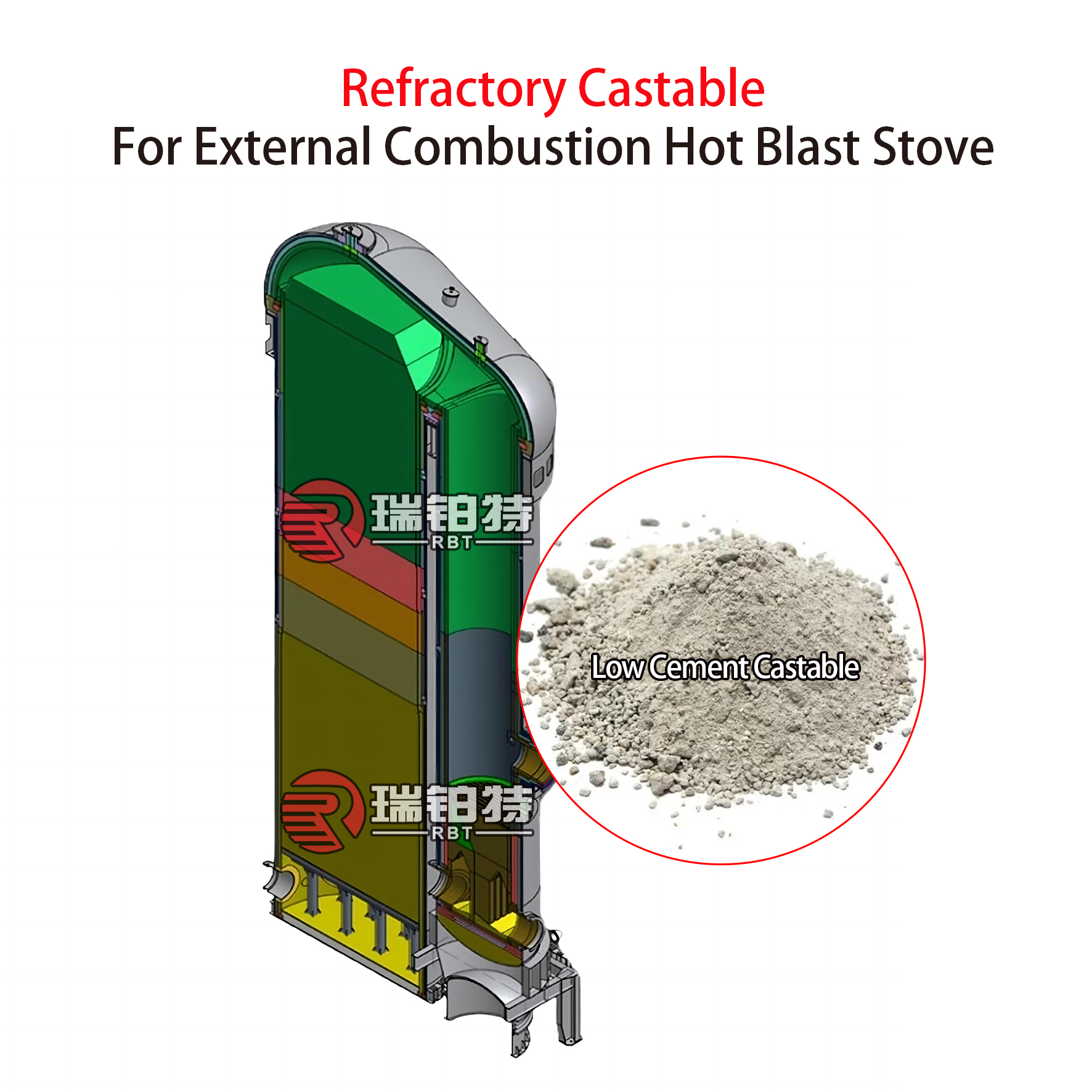

5. Cov castables uas tsis muaj cement ntau:Hais txog cov castables uas muaj cov cement tsawg, feem ntau yog li 5%, thiab qee qhov txawm tias txo qis rau 1% txog 2%. Cov castables qis-cement siv cov khoom me me uas tsis pub tshaj 1μm, thiab lawv cov thermal shock tsis kam, slag tsis kam thiab erosion tsis kam tau zoo dua. Cov castables qis-cement yog qhov tsim nyog rau cov linings ntawm ntau yam cua sov kho cua sov, cua sov cua sov, qhov cub ntsug, qhov cub rotary, hluav taws xob cua sov npog, cua sov tawg qhov, thiab lwm yam.; cov castables qis-cement ntws tus kheej yog qhov tsim nyog rau cov phom tsuag tshuaj tsuag rau cov tshuaj tsuag metallurgy, cov linings kub-resistant hnav-resistant rau petrochemical catalytic cracking reactors, thiab cov linings sab nraud ntawm cua sov cua sov dej txias kav dej.

6. Cov khoom siv hluav taws xob uas tsis yooj yim hnav:Cov khoom tseem ceeb ntawm cov khoom siv refractory uas tiv taus hnav suav nrog cov khoom sib xyaw ua ke, hmoov, cov khoom ntxiv thiab cov khoom khi. Cov khoom siv refractory uas tiv taus hnav yog ib hom khoom siv refractory amorphous uas siv dav hauv metallurgy, petrochemicals, cov ntaub ntawv tsim kho, fais fab thiab lwm yam lag luam. Cov khoom siv no muaj qhov zoo ntawm kev tiv taus kub siab, tiv taus hnav, thiab tiv taus kev yaig. Nws yog siv los kho thiab tiv thaiv cov ntaub ntawm cov khoom siv kub siab xws li lub cub tawg thiab lub boiler kom ua rau lub neej ua haujlwm ntawm cov khoom siv ntev dua.

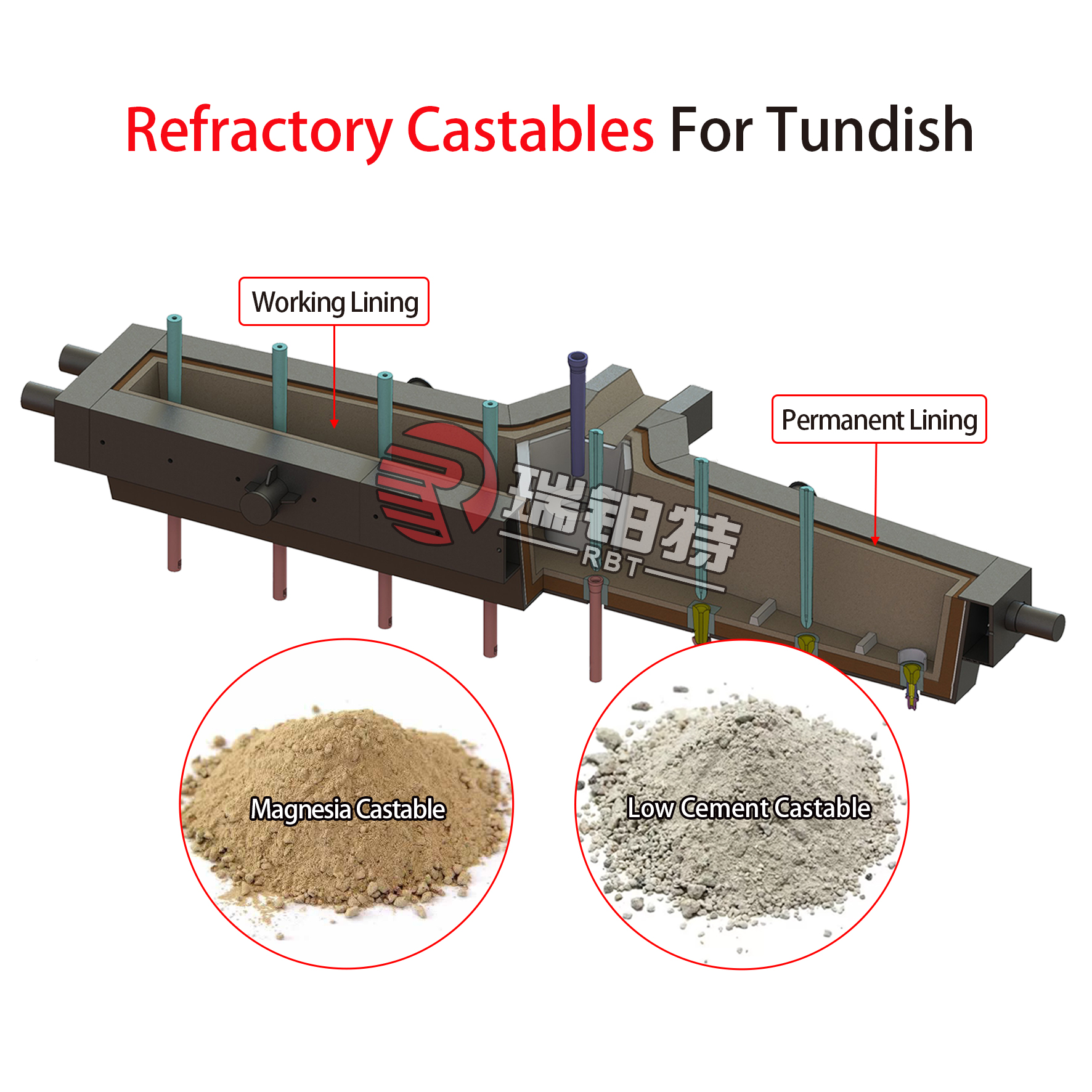

7. Lub lauj kaub castable:Ladle castable yog ib qho amorphous refractory castable ua los ntawm cov khoom zoo siab alumina bauxite clinker thiab silicon carbide ua cov khoom tseem ceeb, nrog rau cov khoom siv aluminate cement binder, dispersant, shrinkage-proof agent, coagulant, explosion-proof fiber thiab lwm yam additives. Vim tias nws muaj cov nyhuv zoo hauv txheej ua haujlwm ntawm lub ladle, nws tseem hu ua txhuas silicon carbide castable.

8. Cov khoom siv hluav taws xob uas tsis hnyav thiab tsis yooj yim tawg:Cov khoom siv hluav taws xob rwb thaiv tsev uas sib dua yog cov khoom siv hluav taws xob rwb thaiv tsev uas muaj qhov hnyav sib dua, muaj zog heev thiab ua tau zoo heev rau kev rwb thaiv tsev kub. Nws feem ntau yog ua los ntawm cov khoom sib xyaw ua ke uas sib dua (xws li perlite, vermiculite, thiab lwm yam), cov khoom siv ruaj khov thaum kub siab, cov khoom sib txuas thiab cov khoom ntxiv. Nws yog siv dav hauv ntau yam khoom siv hauv kev lag luam uas kub siab, xws li cov cub tawg hauv kev lag luam, cov cub tawg kho cua sov, cov cub tawg hlau, cov cub tawg iav yaj, thiab lwm yam, los txhim kho kev siv hluav taws xob ntawm cov khoom siv thiab txo kev siv hluav taws xob.

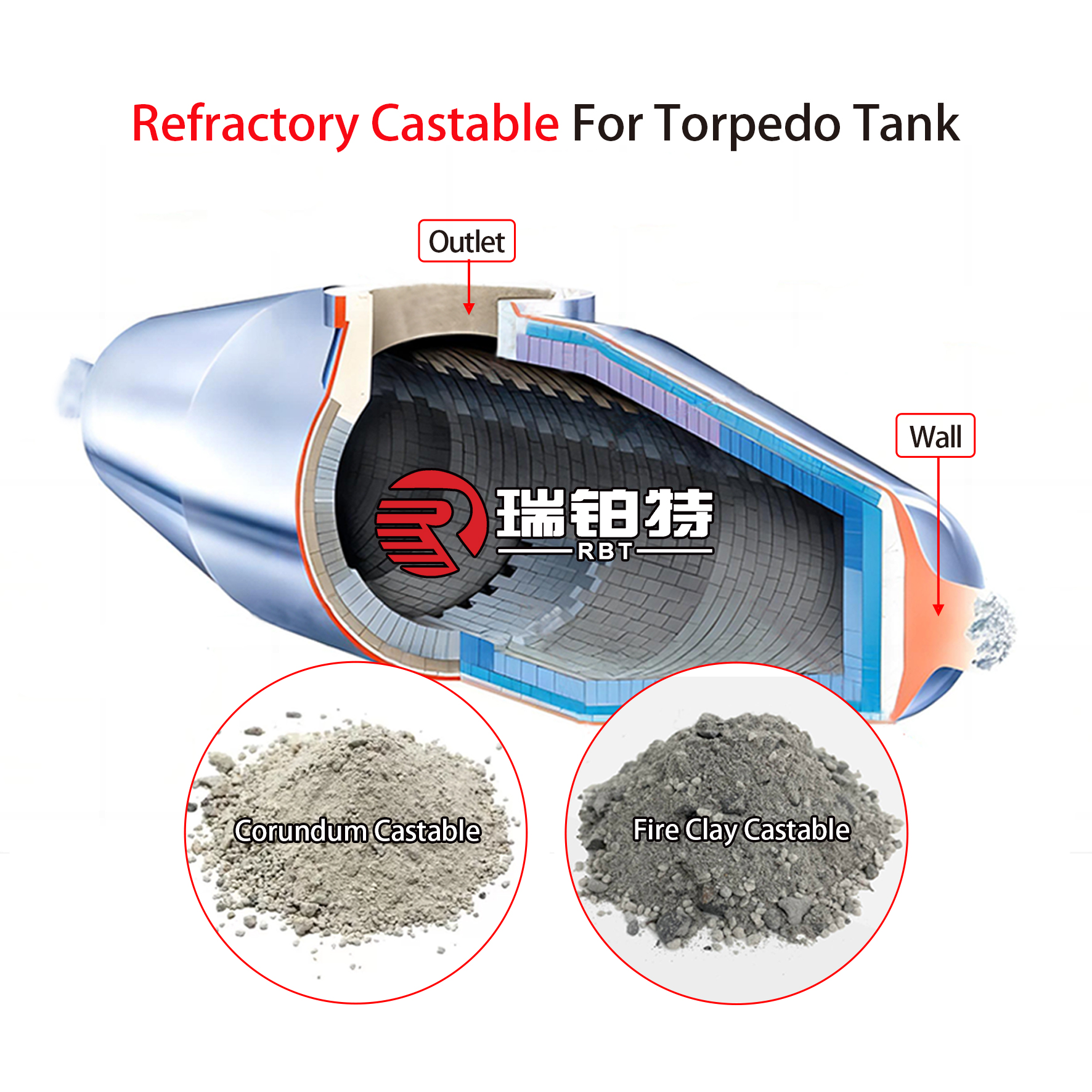

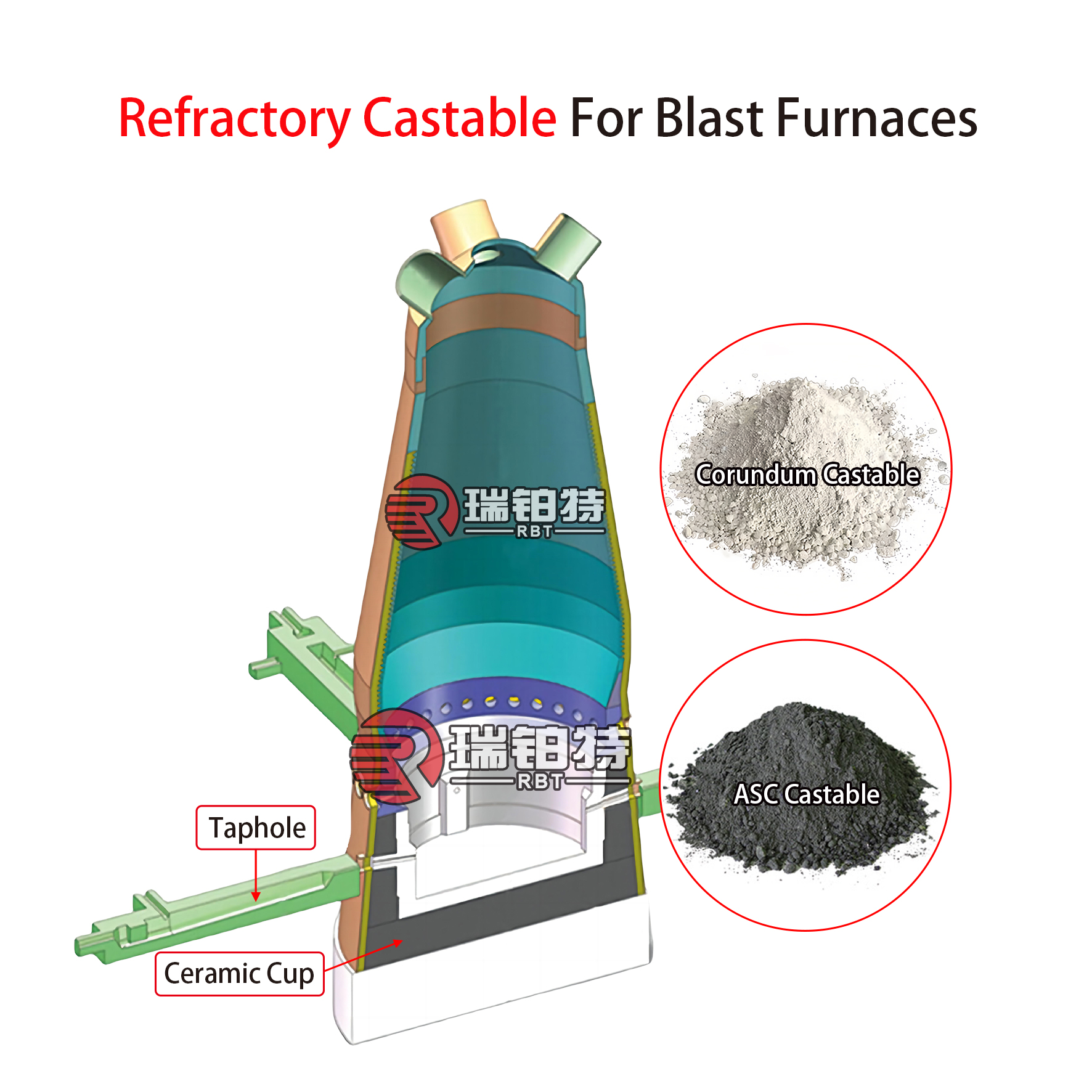

9. Corundum castable:Nrog nws cov kev ua tau zoo heev, corundum castable tau dhau los ua qhov kev xaiv zoo tshaj plaws rau cov khoom tseem ceeb ntawm cov kilns thermal. Cov yam ntxwv ntawm corundum castable yog lub zog siab, qhov kub siab softening thiab zoo slag tsis kam, thiab lwm yam. Qhov kub siv dav dav yog 1500-1800 ℃.

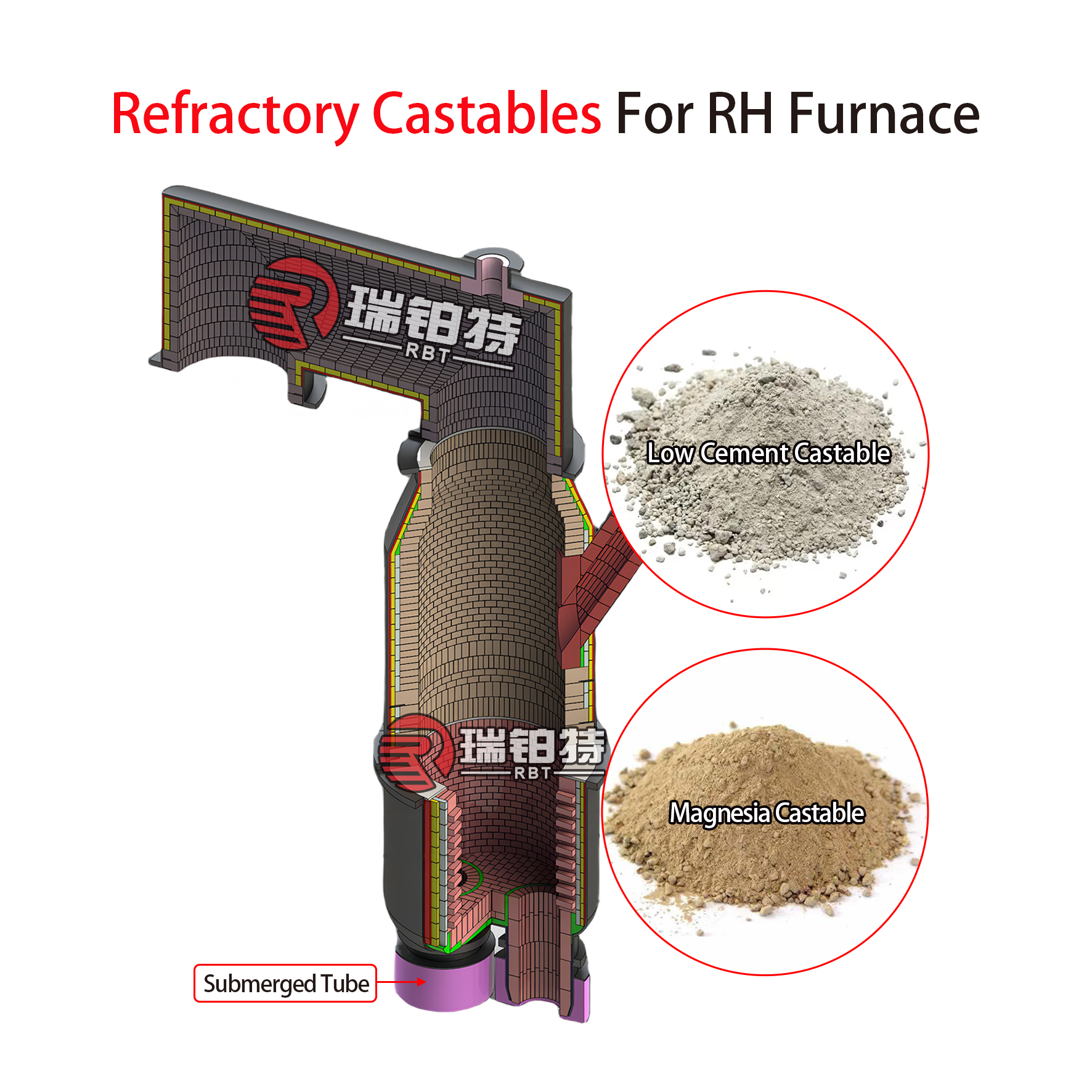

10. Magnesium castable:Feem ntau siv rau hauv cov khoom siv kub thiab txias, nws muaj kev tiv taus zoo heev rau alkaline slag corrosion, qis oxygen potential index thiab tsis muaj kuab paug rau cov hlau molten. Yog li ntawd, nws muaj ntau yam kev siv hauv kev lag luam metallurgical, tshwj xeeb tshaj yog hauv kev tsim cov hlau huv thiab kev lag luam khoom siv hauv tsev.

11. Av nplaum uas siv tau:Cov khoom tseem ceeb yog av nplaum clinker thiab av nplaum sib xyaw, nrog kev ruaj khov zoo thiab qee qhov refractoriness, thiab tus nqi qis dua. Nws feem ntau yog siv rau hauv daim ntaub ntawm cov kilns kev lag luam dav dav, xws li cua sov rauv, annealing rauv, boilers, thiab lwm yam. Nws tuaj yeem tiv taus qee qhov kub ntawm cov cua sov thiab ua lub luag haujlwm hauv kev rwb thaiv tsev kub thiab kev tiv thaiv ntawm lub cev cua sov.

12. Cov castable qhuav:Cov castable qhuav feem ntau yog ua los ntawm cov khoom sib xyaw ua ke, hmoov, cov khoom khi thiab dej. Cov khoom xyaw feem ntau suav nrog av nplaum clinker, tertiary alumina clinker, hmoov zoo heev, CA-50 cement, cov tshuaj dispersants thiab cov tshuaj siliceous lossis feldspar impermeable agents.

Cov castable qhuav muaj peev xwm muab faib ua ntau hom raws li lawv siv thiab cov khoom xyaw. Piv txwv li, cov castable qhuav impermeable feem ntau yog siv rau hauv cov hlwb electrolytic txhuas, uas tuaj yeem tiv thaiv kev nkag mus ntawm electrolytes thiab ntev lub neej kev pabcuam ntawm cov hlwb. Tsis tas li ntawd, cov castable qhuav refractory yog qhov tsim nyog rau cov khoom siv kho vajtse, smelting, kev lag luam tshuaj lom neeg, cov hlau tsis yog ferrous thiab lwm yam lag luam, tshwj xeeb tshaj yog nyob rau hauv kev lag luam hlau, xws li lub qhov ncauj kiln rotary, lub cub tawg, lub hau kiln thiab lwm yam khoom.

Cov Ntaub Ntawv Txog Lub Tuam Txhab

Shandong Robert New Material Co., Ltd. nyob hauv Zibo City, Shandong xeev, Suav teb, uas yog lub hauv paus tsim cov khoom siv refractory. Peb yog lub tuam txhab niaj hnub uas koom ua ke kev tshawb fawb thiab kev txhim kho, kev tsim khoom, kev muag khoom, kev tsim kho qhov cub thiab kev tsim kho, thev naus laus zis, thiab kev xa tawm cov khoom siv refractory. Peb muaj cov khoom siv tiav, thev naus laus zis siab heev, lub zog muaj zog, cov khoom zoo heev, thiab lub koob npe zoo.Peb lub Hoobkas npog ntau tshaj 200 daim av thiab kev tsim khoom txhua xyoo ntawm cov khoom siv refractory zoo li yog kwv yees li 30000 tons thiab cov khoom siv refractory tsis zoo li yog 12000 tons.

Peb cov khoom tseem ceeb ntawm cov ntaub ntawv refractory suav nrog:Cov ntaub ntawv alkaline refractory; cov ntaub ntawv refractory txhuas silicon; cov ntaub ntawv refractory tsis muaj duab; cov ntaub ntawv refractory thermal rwb thaiv tsev; cov ntaub ntawv refractory tshwj xeeb; cov ntaub ntawv refractory ua haujlwm rau cov txheej txheem casting tas mus li.

Cov khoom Robert siv dav hauv cov qhov cub kub siab xws li cov hlau tsis yog ferrous, hlau, cov ntaub ntawv siv hauv tsev thiab kev tsim kho, tshuaj lom neeg, hluav taws xob, kev hlawv pov tseg, thiab kev kho cov khib nyiab phom sij. Lawv kuj siv rau hauv cov hlau thiab hlau xws li ladles, EAF, lub cub tawg, converters, coke ovens, lub cub tawg kub; cov qhov cub metallurgical tsis yog ferrous xws li reverberators, txo qhov cub, lub cub tawg, thiab rotary kilns; cov khoom siv hauv tsev xws li iav kilns, cement kilns, thiab ceramic kilns; lwm cov qhov cub xws li boilers, pov tseg incinerators, roasting furnace, uas tau ua tiav cov txiaj ntsig zoo hauv kev siv. Peb cov khoom raug xa tawm mus rau Southeast Asia, Central Asia, Middle East, Africa, Europe, Americas thiab lwm lub tebchaws, thiab tau tsim kom muaj kev koom tes zoo nrog ntau lub tuam txhab hlau paub zoo. Txhua tus neeg ua haujlwm ntawm Robert zoo siab tos ntsoov yuav ua haujlwm nrog koj rau qhov xwm txheej yeej-yeej.

Cov Lus Nug Feem Ntau

Xav tau kev pab? Nco ntsoov mus saib peb cov rooj sib tham txhawb nqa kom tau cov lus teb rau koj cov lus nug!

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov khoom siv refractory rau ntau tshaj 30 xyoo. Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov kev pabcuam ua ntej muag thiab tom qab muag zoo tshaj plaws.

Rau txhua txoj kev tsim khoom, RBT muaj lub kaw lus QC tiav rau cov tshuaj lom neeg thiab cov khoom siv lub cev. Thiab peb yuav sim cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom. Yog tias koj muaj cov kev xav tau tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws los pab txhawb lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv. Tab sis peb cog lus tias yuav xa khoom sai li sai tau nrog kev lees paub zoo.

Tau kawg, peb muab cov qauv dawb.

Yog, tau kawg, koj tuaj yeem mus xyuas RBT lub tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov khoom siv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb nqa kev txawj ntse thiab kev paub nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov cub tawg sib txawv thiab muab kev pabcuam ib zaug.