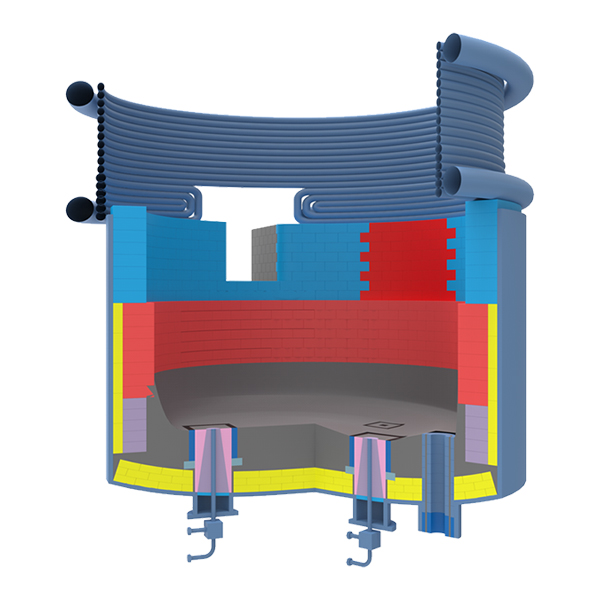

Cov kev cai dav dav rau cov khoom siv refractory rau cov cub hluav taws xob arc yog:

(1) Qhov refractoriness yuav tsum siab. Qhov kub ntawm arc tshaj 4000 ° C, thiab qhov kub ntawm steelmaking yog 1500 ~ 1750 ° C, qee zaum siab txog 2000 ° C, yog li cov ntaub ntawv refractory yuav tsum muaj refractoriness siab.

(2) Qhov kub ntawm kev ua kom mos thaum lub sijhawm thauj khoom yuav tsum siab. Lub cub hluav taws xob ua haujlwm nyob rau hauv qhov kub siab, thiab lub cev cub hluav taws xob yuav tsum tiv taus qhov kev yaig ntawm cov hlau molten, yog li cov khoom siv refractory yuav tsum muaj qhov kub ntawm kev ua kom mos thaum lub sijhawm thauj khoom siab.

(3) Lub zog compressive yuav tsum siab. Lub hauv paus ntawm lub cub hluav taws xob raug cuam tshuam los ntawm kev cuam tshuam ntawm qhov them thaum lub sijhawm them, lub zog static ntawm cov hlau molten thaum lub sijhawm smelting, kev yaig ntawm cov hlau ntws thaum lub sijhawm tapping, thiab kev co tshuab thaum lub sijhawm ua haujlwm. Yog li ntawd, cov khoom siv refractory yuav tsum muaj lub zog compressive siab.

(4) Qhov kev ua kom sov yuav tsum me me. Yuav kom txo qhov poob cua sov ntawm lub cub hluav taws xob thiab txo qhov kev siv hluav taws xob, cov khoom siv refractory yuav tsum muaj qhov ua kom sov tsis zoo, uas yog, qhov coefficient ntawm kev ua kom sov yuav tsum me me.

(5) Kev ruaj khov ntawm qhov kub thiab txias yuav tsum zoo. Hauv ob peb feeb xwb txij li thaum pib siv mus txog thaum them hluav taws xob hauv kev tsim hlau hauv lub cub hluav taws xob, qhov kub yuav poob qis sai sai los ntawm ib puag ncig 1600 ° C mus rau qis dua 900 ° C, yog li cov khoom siv refractory yuav tsum muaj kev ruaj khov ntawm qhov kub thiab txias zoo.

(6) Muaj zog tiv taus xeb. Thaum lub sijhawm ua hlau, slag, roj cua sov thiab hlau molten txhua tus muaj cov tshuaj lom neeg muaj zog rau cov khoom siv refractory, yog li cov khoom siv refractory yuav tsum muaj kev tiv taus xeb zoo.

Kev xaiv cov ntaub ntawv refractory rau phab ntsa sab

Cov cib MgO-C feem ntau yog siv los tsim cov phab ntsa sab ntawm cov cub hluav taws xob uas tsis muaj phab ntsa txias dej. Cov chaw kub thiab cov kab slag muaj cov xwm txheej kev pabcuam hnyav tshaj plaws. Lawv tsis yog tsuas yog raug xeb thiab tawg los ntawm cov hlau molten thiab slag, nrog rau kev cuam tshuam loj heev thaum ntxiv cov khib nyiab, tab sis kuj raug rau cov hluav taws xob thermal los ntawm arc. Yog li ntawd, cov khoom no yog tsim los ntawm cov cib MgO-C nrog kev ua tau zoo heev.

Rau cov phab ntsa sab ntawm cov cub hluav taws xob nrog cov phab ntsa txias dej, vim yog siv cov thev naus laus zis txias dej, qhov kub ntawm cov khoom siv tau nce ntxiv thiab cov xwm txheej siv tau nruj dua. Yog li ntawd, yuav tsum xaiv cov cib MgO-C uas muaj kev tiv thaiv slag zoo, kev ruaj khov thermal shock thiab kev ua haujlwm thermal siab. Lawv cov ntsiab lus carbon yog 10% ~ 20%.

Cov ntaub ntawv refractory rau phab ntsa sab ntawm cov cub hluav taws xob ultra-high-power

Cov phab ntsa sab ntawm cov cub hluav taws xob ultra-high-power (UHP cub tawg) feem ntau yog ua los ntawm MgO-C cib, thiab cov chaw kub thiab cov kab slag yog ua los ntawm MgO-C cib nrog kev ua tau zoo heev (xws li cov cib MgO-C carbon matrix tag nrho). Txhim kho nws lub neej kev pabcuam zoo heev.

Txawm hais tias lub zog ntawm phab ntsa ntawm lub cub tawg tau raug txo qis vim muaj kev txhim kho hauv cov txheej txheem ua haujlwm ntawm lub cub tawg hluav taws xob, nws tseem nyuaj rau cov khoom siv refractory kom ntev lub neej kev pabcuam ntawm cov chaw kub thaum ua haujlwm hauv qab UHP lub cub tawg smelting tej yam kev mob. Yog li ntawd, cov txheej txheem txias dej tau tsim thiab siv. Rau cov cub tawg hluav taws xob siv EBT tapping, thaj chaw txias dej ncav cuag 70%, yog li txo qis kev siv cov khoom siv refractory. Cov txheej txheem txias dej niaj hnub xav tau cov cib MgO-C nrog kev ua kom sov zoo. Asphalt, cov cib magnesia resin-bonded thiab cov cib MgO-C (cov ntsiab lus carbon 5% -25%) yog siv los tsim cov phab ntsa sab ntawm lub cub tawg hluav taws xob. Nyob rau hauv cov xwm txheej oxidation hnyav, cov tshuaj antioxidants raug ntxiv.

Rau cov cheeb tsam kub uas raug puas tsuaj loj tshaj plaws los ntawm cov tshuaj redox, cov cib MgO-C nrog cov magnesite fused crystalline loj ua cov khoom siv raw, cov ntsiab lus carbon ntau dua 20%, thiab cov pa roj carbon tag nrho yog siv rau kev tsim kho.

Qhov kev tsim kho tshiab tshaj plaws ntawm MgO-C cib rau UHP hluav taws xob cub tawg yog siv cov hluav taws kub siab thiab tom qab ntawd impregnation nrog asphalt los tsim cov hu ua fired asphalt-impregnated MgO-C cib. Raws li tuaj yeem pom los ntawm Rooj 2, piv nrog cov cib tsis muaj impregnated, cov pa roj carbon seem ntawm cov cib MgO-C raug hluav taws tom qab asphalt impregnation thiab recarbonization nce li ntawm 1%, qhov porosity txo qis 1%, thiab qhov kub siab flexural zog thiab siab tsis kam yog Lub zog tau zoo dua, yog li nws muaj lub zog siab.

Cov ntaub ntawv refractory magnesium rau phab ntsa hluav taws xob

Cov ntaub thaiv hluav taws xob ntawm lub cub tawg muaj ob hom: alkaline thiab acidic. Cov ntaub thaiv hluav taws xob no siv cov khoom siv alkaline refractory (xws li magnesia thiab MgO-CaO refractory) ua cov ntaub thaiv hluav taws xob, thiab cov ntaub thaiv hluav taws xob no siv cov cib silica, xuab zeb quartz, av dawb, thiab lwm yam los ua cov ntaub thaiv hluav taws xob.

Lus Cim: Rau cov ntaub ntawv hauv lub cub tawg, cov cub tawg hluav taws xob alkaline siv cov ntaub ntawv alkaline refractory, thiab cov cub tawg hluav taws xob acidic siv cov ntaub ntawv acidic refractory.

Lub sijhawm tshaj tawm: Lub Kaum Hli-12-2023