Cov thermocouples yog lub hauv paus ntawm kev saib xyuas qhov kub thiab txias hauv ntau yam txheej txheem kev lag luam - los ntawm kev smelting hlau mus rau kev tsim tshuaj lom neeg. Txawm li cas los xij, lawv cov kev ua tau zoo thiab lub neej nyob ntawm ib qho tseem ceeb: lub raj tiv thaiv. Hauv cov chaw ua haujlwm hnyav, cov raj tiv thaiv thermocouple ib txwm muaj (ua los ntawm hlau, alumina, lossis silicon carbide ntshiab) feem ntau tsis tuaj yeem tiv taus qhov kub heev, cov xov xwm corrosive, lossis cov khoom abrasive. Qhov no ua rau muaj kev hloov pauv thermocouple ntau zaus, cov ntaub ntawv kub tsis raug, thiab lub sijhawm tsim khoom kim heev.

Yog tias koj nkees ntawm kev cuam tshuam rau kev ntseeg tau ntawm thermocouple,Silicon Nitride Bonded Silicon Carbide (NSiC) Thermocouple Protection Tubesyog cov kev daws teeb meem uas hloov pauv qhov kev ua si uas koj xav tau. Tsim los tiv thaiv cov thermocouples hauv cov xwm txheej nyuaj tshaj plaws, NSiC raj ua kom muaj kev ntsuas kub zoo sib xws, raug thaum ua kom lub neej ua haujlwm ntawm koj cov khoom siv ntsuas tseem ceeb.

Vim li cas Silicon Nitride Bonded Silicon Carbide Sawv Tawm rau Kev Tiv Thaiv Thermocouple

Cov raj tiv thaiv thermocouple xav tau qhov sib npaug tshwj xeeb ntawm cov khoom: kev tiv taus cua sov, kev tiv taus corrosion, lub zog kho tshuab, thiab kev ua haujlwm thermal. NSiC ua tau zoo hauv txhua qhov chaw no, ua tau zoo dua cov ntaub ntawv ib txwm muaj hauv txhua qhov tseem ceeb:

1. Kev Tiv Thaiv Kub Heev Rau Kev Tshawb Pom Tsis Tu Ncua

Cov thermocouples hauv kev lag luam xws li kev tsim iav lossis hlau casting ua haujlwm hauv qhov kub tshaj 1,500 ° C. NSiC thermocouple tiv thaiv raj tswj qhov no yooj yim - khav txog qhov kub ua haujlwm tas mus li txog li 1,600 ° C (2,912 ° F) thiab luv luv tiv taus rau 1,700 ° C (3,092 ° F). Tsis zoo li cov raj hlau uas oxidize lossis yaj, lossis cov raj alumina uas tawg hauv qab thermal shock, NSiC tswj kev ncaj ncees txawm tias thaum lub sijhawm kub hloov pauv sai. Qhov no txhais tau tias koj lub thermocouple tseem tiv thaiv, thiab koj cov ntaub ntawv kub tseem raug - tsis hais qhov kub npaum li cas los xij.

2. Kev Tiv Thaiv Kev Xeb Zoo Tshaj Plaws Los Tiv Thaiv Cov Xov Xwm Uas Ntxub Ntxaug

Cov txheej txheem kev lag luam feem ntau ua rau cov thermocouples raug cov hlau molten (txhuas, zinc, tooj liab), cov kua qaub / alkaline, lossis cov pa roj corrosive (sulfur dioxide, chlorine). NSiC qhov ntom ntom, nitride-bonded qauv tsim ib qho impenetrable barrier tiv thaiv cov tshuaj no. Tsis zoo li cov raj silicon carbide ntshiab, uas yog feej oxidized nyob rau hauv cov chaw kub siab noo noo, NSiC cov khoom tshwj xeeb ua rau oxidation tsis kam - xyuas kom meej tias koj lub thermocouple nyob twj ywm tiv thaiv los ntawm corrosion rau ntau xyoo. Qhov no yog qhov tseem ceeb rau cov ntawv thov xws li kev ua tshuaj lom neeg, pov tseg incineration, thiab roj teeb khoom synthesis.

3. Lub Zog Kho Tshuab Zoo Kawg Nkaus Uas Tiv Thaiv Tau Kev Hnav Thiab Kev Cuam Tshuam

Cov thermocouples hauv cov chaw cog cement, cov chaw tsim hluav taws xob, lossis cov chaw ua cov khoom siv hauv av ntsib kev hem thawj tas li: cov hmoov av abrasive, cov khoom ya, thiab kev cuam tshuam ntawm lub tshuab. Cov raj tiv thaiv thermocouple NSiC tau tsim los tiv thaiv cov teeb meem no, nrog lub zog flexural ntau dua 300 MPa thiab Vickers hardness (HV10) ntawm ≥ 1,800. Qhov no ua rau lawv ruaj khov dua li cov raj ib txwm muaj 3–5 npaug, txo qhov xav tau hloov pauv ntau zaus. Rau koj cov haujlwm, qhov no txhais tau tias lub sijhawm tsis ua haujlwm tsawg dua, cov nqi kho qis dua, thiab kev ua haujlwm thermocouple txhim khu kev qha dua.

4. Kev Ua Kub Zoo Tshaj Plaws rau Kev Nyeem Ntawv Sai thiab Tseeb

Tus nqi ntawm lub thermocouple nyob rau hauv nws lub peev xwm los teb sai rau qhov kub hloov pauv. NSiC's thermal conductivity (60–80 W/(m·K)) yog siab dua li ntawm alumina lossis cov raj hlau, ua rau muaj kev hloov pauv cua sov sai los ntawm cov txheej txheem mus rau qhov sib tshuam thermocouple. Qhov no ua kom koj lub thermocouple xa cov ntaub ntawv tiag tiag, raug - tseem ceeb rau kev tswj hwm cov txheej txheem thiab cov khoom zoo. Tsis tas li ntawd, NSiC's qis thermal expansion coefficient (3.5–4.5 × 10⁻⁶/°C) txo qis kev ntxhov siab thermal, tiv thaiv cov kab nrib pleb uas tuaj yeem cuam tshuam qhov tseeb ntawm kev ntsuas.

5. Siv tau ntev thiab pheej yig rau tus nqi qis dua rau kev muaj vaj tse

Txawm hais tias NSiC thermocouple tiv thaiv raj yuav muaj kev nqis peev pib siab dua li cov kev xaiv ib txwm muaj, lawv lub neej ua haujlwm ntev (2-5 xyoos hauv cov xwm txheej hnyav) thiab kev xav tau kev saib xyuas tsawg kawg nkaus ua rau muaj kev txuag nyiaj mus sij hawm ntev. Los ntawm kev txo qhov zaus hloov thermocouple thiab lub sijhawm tsim khoom tsis ua haujlwm, NSiC txo koj cov nqi tag nrho ntawm kev muaj (TCO) thiab txhawb koj cov nyiaj rov qab los ntawm kev nqis peev (ROI). Rau cov nroj tsuag kev lag luam uas tab tom nrhiav kev ua kom zoo dua, qhov no yog qhov kev xaiv ntse, yav tom ntej pov thawj.

Cov Ntawv Thov Tseem Ceeb: Qhov twg NSiC Thermocouple Protection Tubes Muab Cov Txiaj Ntsig

Cov raj tiv thaiv thermocouple NSiC tau tsim los rau cov lag luam uas kev ntseeg tau ntawm thermocouple tsis tuaj yeem sib tham tau. Nov yog cov ntawv thov saum toj kawg nkaus uas lawv ua tau zoo:

1. Kev Rho Hlau thiab Kev Nrum Hlau

Cov Lus Qhia Siv: Tiv thaiv cov thermocouples hauv cov cub tawg uas ua los ntawm txhuas, zinc, tooj liab, thiab hlau.

Cov txiaj ntsig: Tiv taus xeb los ntawm cov hlau yaj thiab kev poob siab thermal thaum lub sijhawm casting, ua kom muaj kev tswj qhov kub kom raug rau qhov zoo ntawm cov hlau.

2. Kev Tsim Khob Iav thiab Khoom Siv Ua Los Ntawm Av nplaum

Cov Qauv Siv: Tiv thaiv cov thermocouples hauv cov cub tawg iav, cov cub tawg ceramic, thiab cov txheej txheem hlawv enamel.

Cov txiaj ntsig: Tiv taus qhov kub thiab txias txog li 1,600°C+ thiab cov iav uas yaj tsis zoo, ua rau cov thermocouples ua haujlwm tau ntau xyoo—tsis tas yuav hloov ntau zaus.

3. Kev Tsim Hluav Taws Xob (Thee, Roj Av, Biomass)

Cov Lus Qhia Siv: Tiv thaiv cov thermocouples hauv cov qhov cub boiler, cov chaw hlawv roj, thiab cov turbines roj.

Cov txiaj ntsig: Tiv taus kev txhuam los ntawm cov tshauv ya thiab kev xeb los ntawm cov pa roj flue (SO₂, NOₓ), ua kom ntseeg tau tias muaj kev soj ntsuam qhov kub ntawm cov pa roj flue thiab txo kev saib xyuas lub chaw tsim hluav taws xob.

4. Kev Ua Tshuaj Lom Zem thiab Petrochemical

Cov Qauv Siv: Kev tiv thaiv cov thermocouples hauv cov reactors, cov kab distillation, thiab cov tank cia kua qaub/alkaline.

Qhov Zoo: Tsis muaj tshuaj lom neeg thiab siab, tiv thaiv cov thermocouples thiab ua kom muaj kev nyab xeeb thiab meej tswj qhov kub ntawm cov txheej txheem.

5. Kev Ua Cement & Minerals

Cov Lus Qhia Siv: Tiv thaiv cov thermocouples hauv cov qhov cub cement, cov tshuab ziab rotary, thiab cov chaw smelting minerals.

Cov txiaj ntsig: Tiv taus kev txhuam hnyav los ntawm cov hmoov av thiab cov khoom me me, thiab qhov kub siab, ua rau lub thermocouple siv tau ntev dua thiab txo cov nqi hloov.

6. Roj teeb & Cov Khoom Siv Hluav Taws Xob Tshiab

Cov Lus Qhia Siv: Tiv thaiv cov thermocouples hauv kev sintering cov khoom siv roj teeb lithium-ion (cathode/anode production) thiab kev tsim cov roj teeb.

Cov txiaj ntsig: Tiv taus cov huab cua corrosive thiab qhov kub siab, ua kom ntseeg tau tias kev tswj qhov kub thiab txias tas li rau cov khoom siv hluav taws xob zoo.

Vim li cas ho xaiv peb cov raj tiv thaiv NSiC Thermocouple?

Ntawm Shandong Robert, peb tshwj xeeb hauv kev tsim cov raj tiv thaiv Silicon Nitride Bonded Silicon Carbide Thermocouple uas ua tau zoo heev uas tsim los kom tau raws li qhov xav tau tshwj xeeb ntawm kev ntsuas kub hauv kev lag luam. Peb cov khoom muaj:

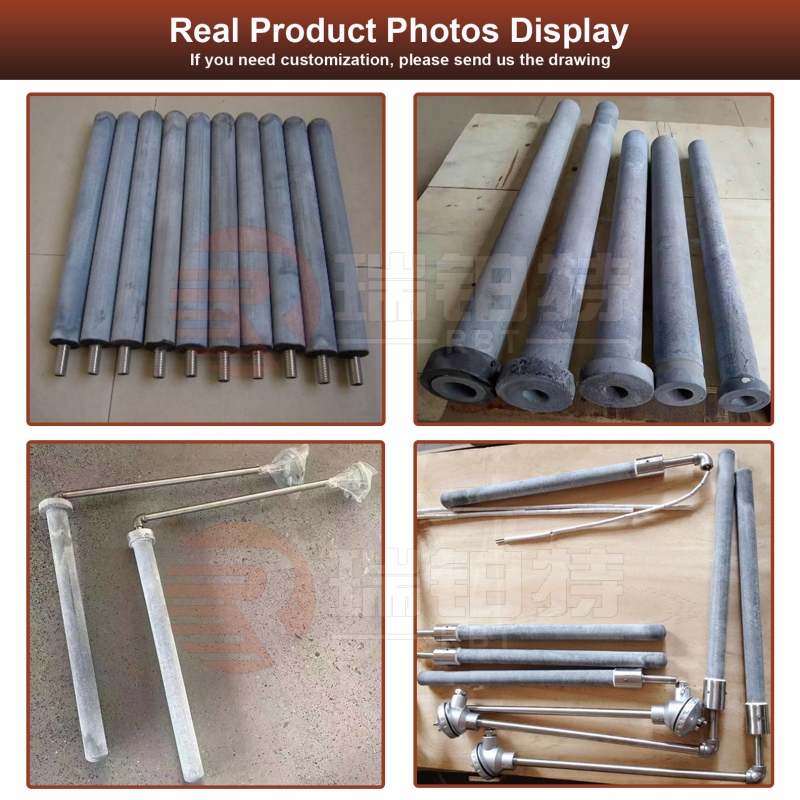

Kev Sib Tw Zoo Tshaj Plaws ntawm Thermocouple:Muaj ntau qhov loj (OD 8–50 mm, ntev 100–1,800 mm) thiab cov qauv teeb tsa (ncaj, xov, flanged) kom haum rau txhua hom thermocouple txheem (K, J, R, S, B).

Kev Tsim Kho Kom Zoo:Txhua lub raj yog tsim los nrog kev kam rau siab kom ntseeg tau tias haum zoo, tiv thaiv kev xau ntawm cov xov xwm thiab tiv thaiv koj lub thermocouple.

Kev Ntsuas Zoo:Txhua lub raj xa dej raug kuaj xyuas nruj rau qhov ceev, lub zog, kev tiv thaiv corrosion, thiab kev ua haujlwm thermal.

Kev Txhawb Nqa Thoob Ntiaj Teb:Peb muab kev xa khoom sai, kev sab laj txog kev siv tshuab, thiab kev pabcuam tom qab muag kom pab koj koom ua ke peb cov raj dej rau hauv koj cov txheej txheem tau yooj yim.

Npaj Txhij Tiv Thaiv Koj Cov Thermocouples & Txhim Kho Koj Cov Txheej Txheem?

Tsis txhob cia cov raj tiv thaiv tsis zoo ua rau koj lub thermocouple ua haujlwm tsis zoo lossis koj cov nyiaj tau los poob qis. Hloov kho mus rau Silicon Nitride Bonded Silicon Carbide Thermocouple Protection Tubes thiab paub txog lub neej thermocouple ntev dua, cov ntaub ntawv kub raug dua, thiab cov nqi kho qis dua.

Tiv tauj peb hnub no kom tau txais cov qauv dawb, kev hais nqe raws li koj xav tau, lossis kev sab laj txog kev siv tshuab. Cia peb pab koj ua kom koj cov txheej txheem kev lag luam khiav mus zoo - nrog rau kev tiv thaiv thermocouple txhim khu kev qha tshaj plaws hauv kev ua lag luam.

Lub sijhawm tshaj tawm: Cuaj hlis-11-2025