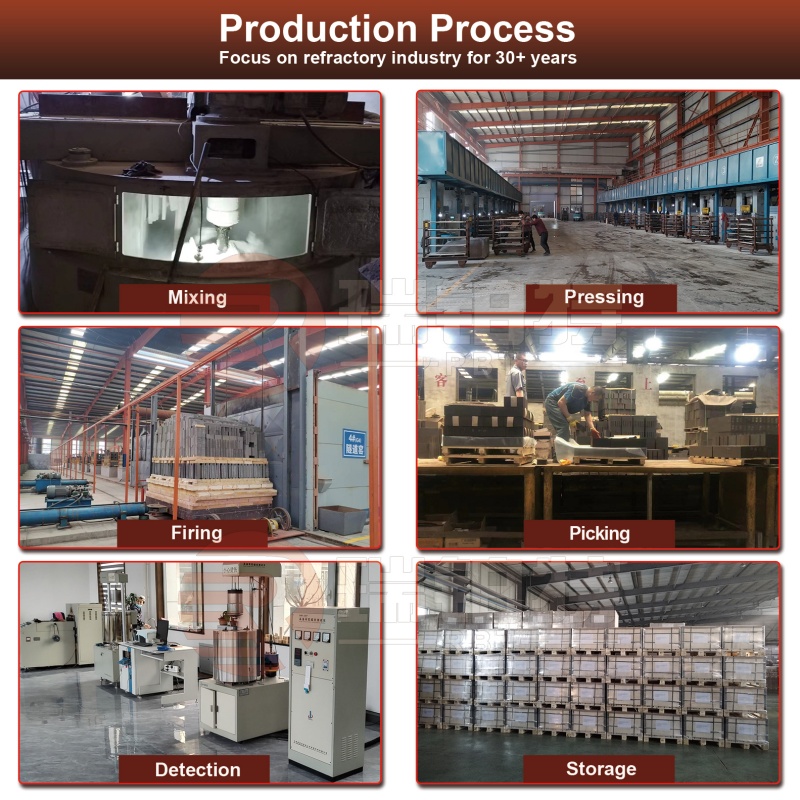

Hauv thaj chaw ntawm cov chaw ua kom sov kub (xws li cov tshuab hloov pauv hlau, cov tais diav, thiab cov chaw ua kom tawg),cov cib magnesium carbonSawv tawm ua cov khoom siv refractory tseem ceeb, ua tsaug rau lawv qhov kev tiv taus corrosion zoo heev, kev ruaj khov kub siab, thiab kev tiv taus thermal shock. Cov txheej txheem tsim cov cib no yog kev sib xyaw ua ke ntawm thev naus laus zis thiab kev ua kom raug - txhua kauj ruam txiav txim siab qhov zoo ntawm cov khoom kawg. Hauv qab no, peb coj koj mus rau hauv cov txheej txheem tsim khoom tiav ntawm cov cib magnesium carbon, qhia txog peb yuav ua li cas kom ntseeg tau tias txhua lub cib ua tau raws li cov qauv qib kev lag luam.

1. Kev Xaiv Khoom Siv Raw: Lub Hauv Paus ntawm Cov Cib Magnesium Carbon Zoo

Qhov zoo ntawm cov khoom siv raw yog thawj kab tiv thaiv rau kev ua tau zoo ntawm magnesium carbon cib. Peb ua raws li cov qauv xaiv nruj kom ntseeg tau tias txhua yam khoom ua tau raws li cov qauv siab:

Cov Khoom Siv Magnesia Uas Muaj Peev Xwm Siab:Peb siv cov magnesia fused lossis sintered magnesia nrog cov ntsiab lus MgO ntau dua 96%. Cov khoom siv raw no muab cov cib nrog kev tiv taus kub siab thiab kev tiv taus corrosion, zoo tiv taus kev yaig ntawm cov hlau molten thiab slag hauv cov cub tawg.

Cov Khoom Siv Carbon Qib Siab:Xaiv cov graphite flake uas muaj cov pa roj carbon ntau tshaj 90%. Nws cov qauv txheej txheem ua rau lub cib tiv taus cua sov, txo qhov kev pheej hmoo ntawm kev tawg vim qhov kub hloov pauv sai thaum lub sijhawm ua haujlwm ntawm lub cub tawg.

Phau Ntawv Pov Thawj Zoo Tshaj Plaws:Cov tshuaj phenolic resin (hloov kho kom tiv taus kub siab) yog siv ua cov khoom sib txuas. Nws ua kom muaj kev sib txuas zoo ntawm magnesia thiab graphite, thaum tiv thaiv kev ua kom yaj lossis lwj thaum kub siab, uas yuav cuam tshuam rau kev ua kom lub cib ruaj khov.

Cov Khoom Siv Ntxiv:Muaj me ntsis cov tshuaj antioxidants (xws li hmoov txhuas, hmoov silicon) thiab cov khoom siv sintering ntxiv rau kom tiv thaiv kev oxidation ntawm graphite thiab txhim kho qhov ceev ntawm lub cib. Txhua yam khoom siv raw yuav tsum tau kuaj xyuas 3 zaug kom tshem tawm cov khoom tsis huv uas yuav ua rau kev ua haujlwm tsis zoo.

2. Kev tsoo thiab kev ua kom cov khoom sib xyaw: Kev tswj qhov loj ntawm cov khoom me me kom raug rau cov qauv sib xws

Kev faib cov khoom me me sib npaug yog qhov tseem ceeb rau kev ua kom ntseeg tau tias cov cib magnesium carbon muaj qhov ceev thiab lub zog. Cov theem no ua raws li cov kev cai nruj:

Txheej Txheem Sib Tsoo:Ua ntej, cov magnesia loj thiab graphite raug tsoo ua tej daim me me siv cov tshuab tsoo puab tsaig thiab cov tshuab tsoo uas cuam tshuam. Qhov ceev ntawm kev tsoo yog tswj ntawm 20-30 rpm kom tsis txhob kub dhau thiab ua puas rau cov qauv khoom siv raw.

Kev Tshuaj Xyuas thiab Kev Faib Pawg:Cov khoom siv uas raug tsoo raug tshuaj xyuas los ntawm ntau txheej vibrating screens (nrog mesh loj ntawm 5mm, 2mm, thiab 0.074mm) kom cais lawv ua cov pob zeb loj (3-5mm), cov pob zeb nruab nrab (1-2mm), cov pob zeb me me (0.074-1mm), thiab cov hmoov zoo heev (<0.074mm). Qhov yuam kev ntawm qhov loj ntawm cov khoom me me raug tswj hwm hauv ±0.1mm.

Kev sib xyaw ua ke ntawm cov granule:Cov khoom me me sib txawv sib xyaw ua ke hauv lub tshuab sib tov ceev ceev li 10-15 feeb ntawm qhov ceev ntawm 800 rpm. Qhov no ua kom txhua pawg ntawm cov hmoov av muaj cov khoom sib xws, tsim kom muaj lub hauv paus rau kev sib npaug ntawm cov cib.

3. Kev Sib Tov thiab Kev Sib Zov: Ua kom muaj kev sib txuas zoo ntawm cov khoom sib xyaw

Cov theem sib tov thiab sib tsoo txiav txim siab qhov sib txuas ntawm cov khoom siv raw. Peb siv cov khoom sib tov ob chav helix siab heev thiab tswj hwm cov xwm txheej ntawm cov txheej txheem nruj me ntsis:

Ua Ntej Sib Tov Cov Khoom Qhuav:Cov pob zeb loj, nruab nrab, thiab me me raug sib xyaw ua ntej kom qhuav rau 5 feeb kom ntseeg tau tias txhua yam khoom sib npaug. Kauj ruam no zam kev sib sau ua ke ntawm cov pa roj carbon lossis magnesia hauv zos, uas yuav ua rau muaj kev sib txawv ntawm kev ua haujlwm.

Ntxiv Binder thiab Kneading:Muab cov phenolic resin uas tau hloov kho (ua kom sov txog 40-50 ℃ kom nws nplaum zoo dua) ntxiv rau hauv cov khoom sib tov qhuav, tom qab ntawd muab nws sib tov li 20-25 feeb. Qhov kub ntawm lub mixer no khaws cia ntawm 55-65 ℃, thiab lub siab tswj tau ntawm 0.3-0.5 MPa—qhov no ua kom cov binder qhwv txhua lub khoom me me, ua kom muaj cov qauv "magnesia-graphite-binder" ruaj khov.

Kev Ntsuas Kev Sib Xws:Tom qab sib tov tag, yuav kuaj seb qhov sib tov puas sib xws txhua 10 feeb. Qhov sib xws zoo tshaj plaws yog 30-40 (ntsuas los ntawm lub ntsuas qhov sib xws); yog tias nws qhuav dhau los yog ntub dhau, qhov koob tshuaj ntawm cov khoom sib txuas lossis lub sijhawm sib tov yuav raug hloov kho tam sim ntawd.

4. Kev Tsim Kho: Kev Tsim Kho Siab Rau Qhov Ceev Thiab Lub Zog

Kev nias ua yog cov kauj ruam uas ua rau cov cib magnesium carbon zoo li qub thiab ua kom muaj qhov ceev ceev. Peb siv cov tshuab nias hydraulic tsis siv neeg nrog kev tswj siab meej:

Kev Npaj Pwm:Cov pwm hlau uas ua raws li tus neeg siv khoom xav tau (raws li qhov loj ntawm cib, xws li 230 × 114 × 65mm lossis cov duab tshwj xeeb) raug ntxuav thiab pleev nrog cov tshuaj tso tawm kom tiv thaiv cov khoom sib xyaw kom tsis txhob lo rau pwm.

Kev Nias Siab Siab:Cov khoom sib tov uas tau sib tov lawm raug nchuav rau hauv pwm, thiab lub tshuab hydraulic nias lub zog ntawm 30-50 MPa. Qhov ceev nias yog teem rau 5-8 mm/s (nias qeeb qeeb kom tshem tawm cov pa npuas) thiab tuav rau 3-5 vib nas this. Cov txheej txheem no ua kom lub cib qhov ceev ntawm 2.8-3.0 g/cm³, nrog rau qhov porosity tsawg dua 8%.

Kev rhuav tshem thiab kev tshuaj xyuas:Tom qab nias, cov cib yuav raug rhuav tshem thiab kuaj xyuas seb puas muaj qhov tsis zoo ntawm qhov chaw (xws li tawg, ntug tsis sib npaug). Cov cib uas muaj qhov tsis zoo yuav raug tshem tawm tam sim ntawd kom tsis txhob nkag mus rau hauv cov txheej txheem tom ntej.

5. Kev Kho Mob Kub (Kho): Txhim Kho Kev Sib Txuas thiab Kev Ruaj Ntseg ntawm Cov Khoom Sib Txuas

Kev kho cua sov (curing) ua kom cov khoom sib txuas ua ke zoo dua thiab tshem tawm cov tshuaj uas yaj tau ntawm cov cib. Peb siv cov qhov cub qhov av nrog kev tswj qhov kub kom meej:

Kev Ua Kub Kauj Ruam: Cov cib raug muab tso rau hauv lub qhov cub qhov av, thiab qhov kub raug tsa kauj ruam:

20-80 ℃ (2 teev):Ua kom cov dej noo ntawm qhov chaw qhuav;

80-150 ℃ (4 teev):Txhawb kom cov resin kho ua ntej;

150-200 ℃ (6 teev):Kev sib txuas thiab kho cov resin tiav tag nrho;

200-220 ℃ (3 teev):Ua kom lub cib ntsa ruaj khov.

Qhov kub ntawm qhov kub thiab txias raug tswj ntawm 10-15 ℃ / teev kom tiv thaiv kev tawg vim yog kev ntxhov siab ntawm cua sov.

Kev Tshem Tawm Cov Khoom Uas Tsis Muaj Zog:Thaum lub sijhawm kho, cov khoom uas yaj tau (xws li cov resins me me) raug tso tawm los ntawm lub qhov cub cua tso pa tawm, ua kom lub cib sab hauv muaj qhov ntom thiab tsis muaj qhov khoob.

Cov Txheej Txheem Txias: Tom qab kho kom qhuav, cov cib raug txias rau qhov kub hauv chav tsev ntawm tus nqi 20 ℃ / teev. Tsis txhob txias sai sai kom tiv thaiv kev puas tsuaj los ntawm cua sov.

6. Kev Ua Tom Qab Ua tiav thiab Kev Tshuaj Xyuas Zoo: Xyuas kom meej tias txhua lub cib ua tau raws li cov qauv

Cov theem kawg ntawm kev tsim khoom tsom mus rau kev ua tiav qhov tseeb thiab kev kuaj xyuas zoo kom ntseeg tau tias txhua lub cib magnesium carbon ua tau raws li cov kev cai ntawm kev siv hauv kev lag luam:

Kev Sib Tsoo thiab Kev Txiav:Cov cib uas muaj cov npoo tsis sib npaug raug sib tsoo siv cov tshuab sib tsoo CNC, kom ntseeg tau tias qhov yuam kev ntawm qhov ntev yog nyob hauv ± 0.5 hli. Cov cib uas muaj cov duab tshwj xeeb (xws li cov cib uas zoo li lub voj voog rau cov khoom hloov pauv) raug ua tiav los ntawm kev siv 5-axis machining centers kom phim cov kab nkhaus sab hauv ntawm lub cub tawg.

Kev Ntsuas Zoo Tag Nrho:Txhua pawg cib raug kuaj 5 qhov tseem ceeb:

Kev Ntsuas Qhov Ceev thiab Qhov Porosity:Siv txoj kev Archimedes, xyuas kom meej tias qhov ceev ntawm cov khoom yog ≥2.8 g/cm³ thiab porosity ≤8%.

Kev Ntsuas Lub Zog Nqus:Sim lub zog compressive ntawm lub cib (≥25 MPa) siv lub tshuab kuaj thoob ntiaj teb.

Kev Ntsuas Kev Tiv Thaiv Kev Kub Ntxhov Thermal:Tom qab 10 lub voj voog ntawm kev ua kom sov (1100 ℃) thiab txias (kub hauv chav), xyuas seb puas muaj qhov tawg (tsis pub pom qhov tawg).

Kev Ntsuas Kev Tiv Thaiv Kev Kub Ntxhov:Ua qauv qhia txog tej yam xwm txheej ntawm lub cub tawg kom sim seb lub cib puas tiv taus kev yaig ntawm cov slag uas yaj (kev yaig ntawm tus nqi ≤0.5 hli/teev).

Kev Tshuaj Xyuas Txog Cov Tshuaj Lom Zem:Siv cov tshuaj X-ray fluorescence spectrometry los xyuas kom meej cov ntsiab lus MgO (≥96%) thiab cov ntsiab lus carbon (8-12%).

Ntim thiab Khaws Cia:Cov cib uas tsim nyog tau ntim rau hauv cov thawv uas tsis ntub dej lossis cov ntoo pallets, nrog rau daim zaj duab xis uas tsis ntub dej qhwv ib ncig kom tsis txhob nqus dej thaum lub sijhawm thauj mus los. Txhua pob khoom muaj daim ntawv lo nrog tus lej pawg, hnub tsim khoom, thiab daim ntawv pov thawj tshuaj xyuas zoo kom taug qab tau.

Vim li cas ho xaiv peb cov Magnesium Carbon Cib?

Peb cov txheej txheem tsim khoom nruj heev (txij li kev xaiv cov khoom siv raw mus rau kev ua tiav tom qab) ua kom peb cov cib magnesium carbon muaj kev ua tau zoo heev hauv cov cub tawg kub siab. Txawm hais tias rau cov khoom siv hloov pauv hlau, cov tais diav, lossis lwm yam khoom siv kub siab, peb cov khoom tuaj yeem:

Tiv taus qhov kub txog li 1800 ℃ yam tsis muaj kev mos lossis deformation.

Tiv taus cov hlau yaj thiab cov slag erosion, ua rau lub cub tawg lub neej ua haujlwm ntev dua 30%+.

Txo cov zaus kho thiab cov nqi tsim khoom rau cov neeg siv khoom.

Peb muab cov kev daws teeb meem raws li koj lub cub tawg hom, qhov loj me, thiab cov xwm txheej ua haujlwm. Tiv tauj peb hnub no kom paub ntau ntxiv txog peb cov txheej txheem tsim cov cib magnesium carbon lossis kom tau txais tus nqi dawb!

Lub sijhawm tshaj tawm: Lub Kaum Hli-29-2025