Cov cib ntsayog cov khoom siv tshwj xeeb uas tsis yooj yim tawg, feem ntau yog siv rau kev kho thiab txhawb nqa phab ntsa sab hauv ntawm lub qhov cub kom ntseeg tau tias lub qhov cub ruaj khov thiab ruaj khov nyob rau hauv qhov kub siab thiab qhov chaw ua haujlwm hnyav. Cov cib anchor raug kho rau phab ntsa sab hauv ntawm lub qhov cub los ntawm cov anchors tshwj xeeb, uas tuaj yeem tiv taus qhov kub siab, cua ntws thiab cov khoom hnav, yog li ua kom lub neej ua haujlwm ntawm lub qhov cub ntev dua thiab tswj hwm qhov ruaj khov ntawm qhov chaw ua haujlwm.

Khoom siv thiab duab

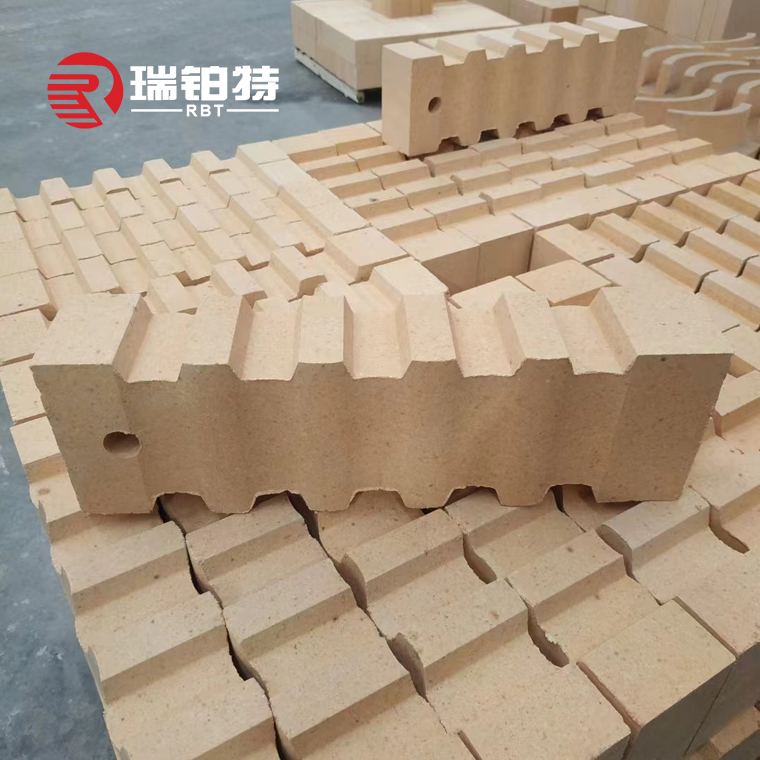

Cov cib ntsa feem ntau yog ua los ntawm cov khoom siv refractory xws li cov txhuas siab, magnesium, silicon lossis chromium, uas muaj kev ruaj khov zoo heev thiab tiv taus corrosion ntawm qhov kub siab. Nws cov duab thiab qhov loj me yog kho raws li cov qauv tshwj xeeb thiab cov txheej txheem xav tau ntawm lub cub tawg. Cov duab feem ntau suav nrog cov duab plaub fab, puag ncig thiab cov duab tshwj xeeb.

Daim ntawv thov teb

1. Kev lag luam casting: siv rau kev casting cov alloys kub siab xws li cov alloys txhuas, stainless hlau, nickel-based alloys thiab titanium alloys.

2. Kev lag luam hlau: siv rau kev sib txuas thiab kho cov khoom siv kub siab xws li cov tshuab ua kom tiav tas mus li, cov tshuab ua hlau arc, cov hloov pauv, cov cua sov kub, cov cua sov tawg thiab cov pas dej desulfurization.

3. Kev lag luam cement: siv rau kev kho thiab txhawb cov khoom siv xws li lub qhov cub rotary, lub tshuab txias, lub tshuab ua ntej cua sov, thiab lwm yam.

4. Kev lag luam petrochemical: siv rau kev kho thiab txhawb nqa cov chaw xws li cov kav dej thiab cov tso tsheb cia khoom hauv cov chaw ua roj.

5. Kev lag luam fais fab: siv rau kev kho thiab txhawb cov khoom siv xws li boilers hauv cov chaw tsim hluav taws xob, cov cub tawg thiab cov tails ntawm cov chaw tsim hluav taws xob thermal thiab roj.

Cov yam ntxwv ntawm cov qauv

Cov cib ntsa anchor feem ntau yog ua los ntawm cov qhov kawg dai thiab lub cev anchor, thiab muaj cov qauv kem. Qhov saum npoo ntawm lub cev anchor muaj cov grooves thiab tav uas faib ua ntu zus. Cov tav ua lub luag haujlwm hauv kev txhawb nqa thiab rub, txhim kho lub zog tensile thiab flexural thiab tiv thaiv kev tawg. Tsis tas li ntawd, cov cib ntsa anchor kuj muaj cov yam ntxwv ntawm qhov ntim ntim siab, lub zog compressive siab, muaj zog tiv thaiv spalling, zoo thermal shock stability thiab muaj zog tiv thaiv kev cuam tshuam.

Lub sijhawm tshaj tawm: Tsib Hlis-16-2025