Kev Taw Qhia

Hauv cov lag luam kub siab—txij li kev ua hlau mus rau kev tsim iav—cov khoom siv refractory yog lub hauv paus ntawm kev ua haujlwm nyab xeeb thiab ua haujlwm tau zoo. Ntawm cov no,cov cib mullitesawv tawm rau lawv qhov kev ruaj khov thermal zoo kawg nkaus, kev tiv thaiv corrosion, thiab lub zog kho tshuab. Kev nkag siab txog lawv cov kev faib tawm thiab daim ntawv thov yog qhov tseem ceeb rau cov lag luam nrhiav kev ua kom lub neej khoom siv zoo dua thiab txo cov nqi ua haujlwm. Tsab xov xwm no rhuav tshem cov hom tseem ceeb ntawm mullite cib thiab lawv cov kev siv hauv ntiaj teb tiag tiag, pab koj txiav txim siab zoo rau koj cov kev xav tau kev lag luam.

Kev faib tawm ntawm Mullite Bricks

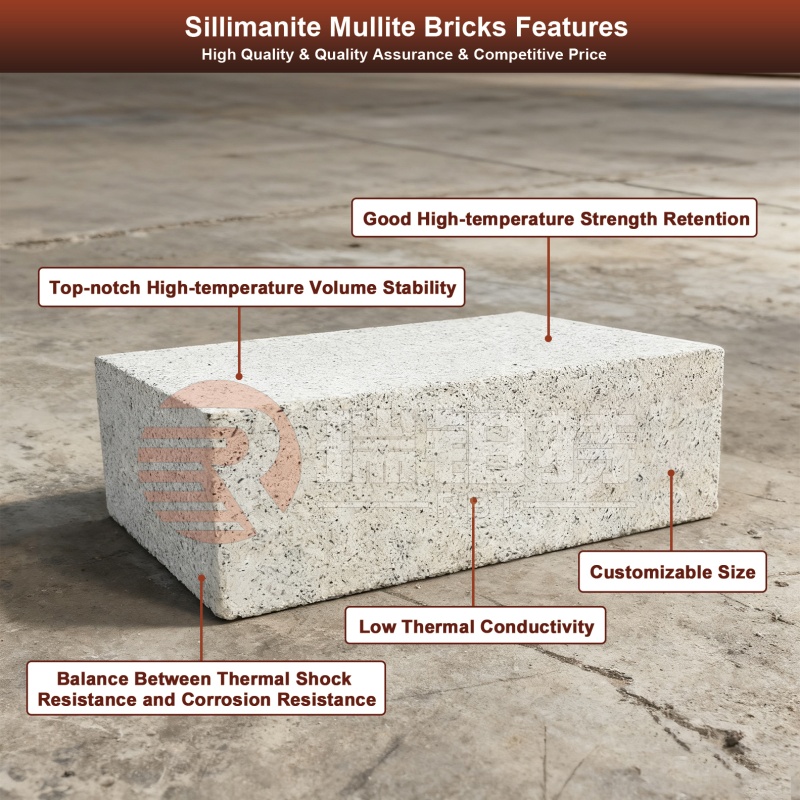

Cov cib mullite raug faib ua pawg raws li cov txheej txheem tsim khoom thiab cov khoom ntxiv, txhua yam raug tsim los rau cov kev xav tau tshwj xeeb hauv kev lag luam.

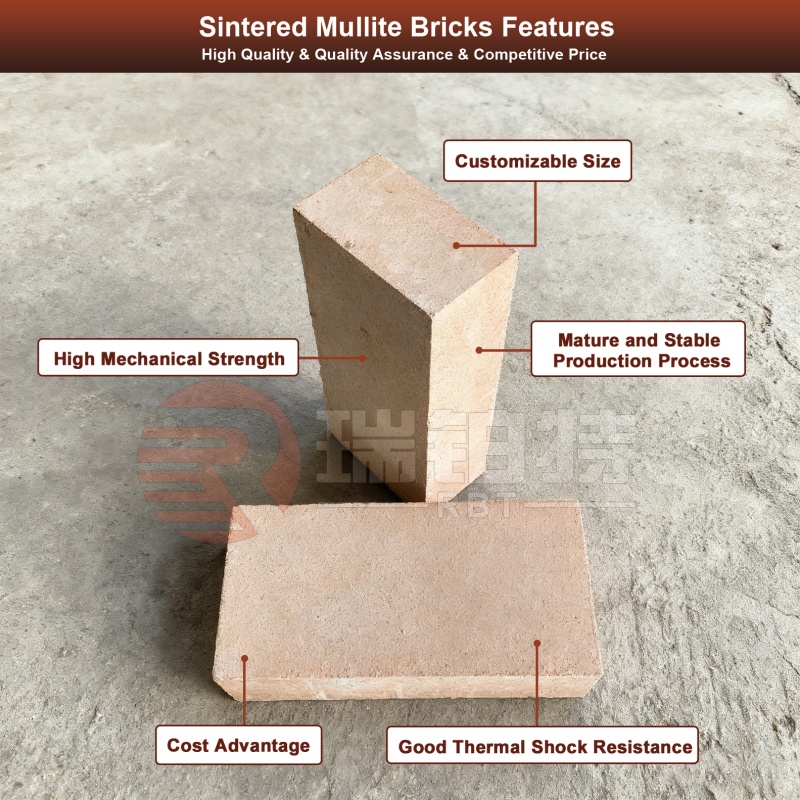

1. Cov Cib Mullite Sintered

Ua los ntawm kev sib xyaw cov alumina thiab silica uas muaj cov khoom huv si, ua kom cov khoom sib xyaw zoo, thiab sintering nws ntawm qhov kub siab tshaj 1600 ° C, cov cib mullite sintered muaj cov qauv ntom ntom thiab porosity tsawg (feem ntau qis dua 15%). Cov yam ntxwv no ua rau lawv tiv taus kev hnav zoo heev thiab tiv taus kev poob siab thermal - zoo tagnrho rau cov chaw uas muaj kev hloov pauv kub ntau zaus. Kev siv dav dav suav nrog cov ntaub rau cov qhov cub ceramic, lub qhov cub tawg kub, thiab cov chav hlawv boiler.

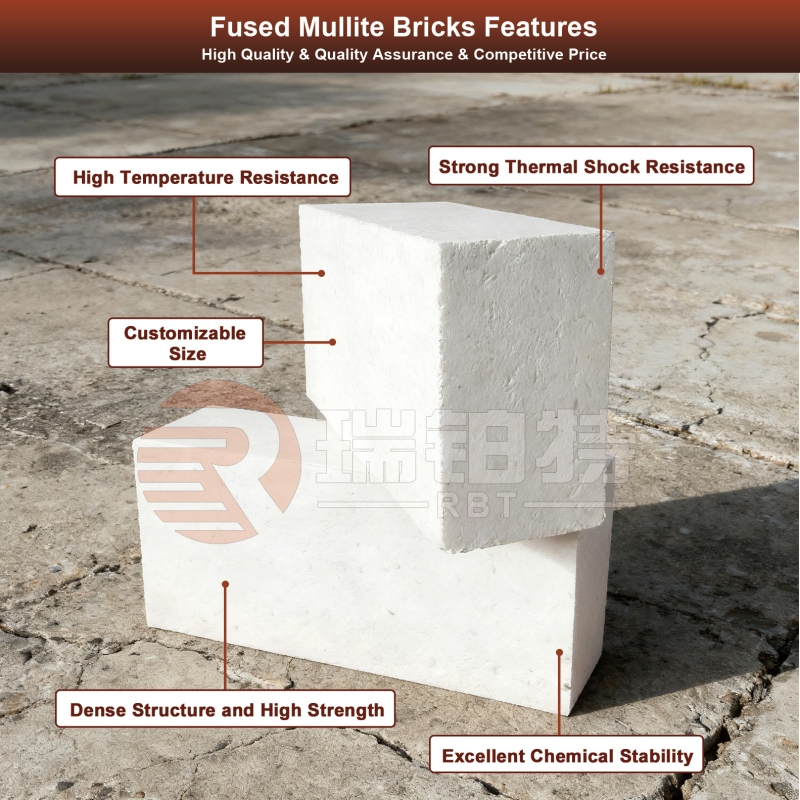

2. Cov Cib Fused-cast Mullite

Tsim los ntawm kev yaj cov khoom siv raw (alumina, silica) hauv lub cub hluav taws xob arc (dhau 2000 ° C) thiab pov cov khoom sib tov rau hauv pwm, cov cib fim fused-cast mullite muaj cov qib tsis huv ultra-low thiab cov khoom siv crystalline purity siab. Lawv qhov kev tiv thaiv zoo dua rau kev yaig tshuaj (piv txwv li, los ntawm cov iav molten lossis slags) ua rau lawv yog qhov kev xaiv zoo tshaj plaws rau cov khoom siv rov ua dua tshiab rau lub cub tawg iav, cov dab dej iav ntab, thiab lwm yam khoom siv uas raug rau cov xov xwm molten hnyav.

3. Cov Cib Mullite Uas Sib Dua

Tsim los ntawm kev ntxiv cov neeg sawv cev tsim cov qhov (piv txwv li, sawdust, graphite) thaum lub sijhawm tsim khoom, cov cib mullite sib dua muaj qhov porosity ntawm 40-60% thiab qhov ceev qis dua li cov hom sintered lossis fused-cast. Lawv qhov zoo tseem ceeb yog qhov thermal conductivity qis (0.4-1.2 W / (m · K)), uas txo qhov poob cua sov. Lawv siv dav ua cov txheej rwb thaiv tsev hauv cov qhov cub, cov cub tawg, thiab cov khoom siv kho cua sov, qhov twg qhov hnyav thiab kev siv hluav taws xob zoo yog qhov tseem ceeb.

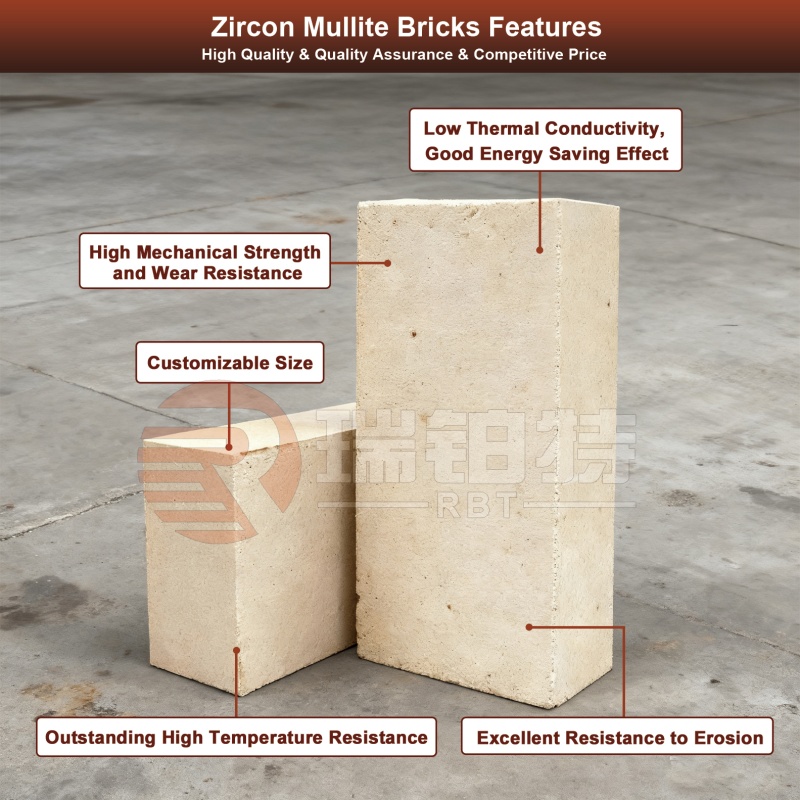

4. Cov Cib Zircon Mullite

Los ntawm kev siv zircon (ZrSiO₄) rau hauv cov khoom siv raw, cov cib zircon mullite tau txais kev ua haujlwm kub siab dua - lawv tuaj yeem tiv taus qhov kub txog li 1750 ° C thiab tiv taus kev yaig los ntawm cov kua qaub slags. Qhov no ua rau lawv haum rau cov chaw ib puag ncig hnyav xws li cov cub tawg hlau uas tsis yog ferrous (piv txwv li, cov hlwb txo cov txhuas) thiab cov chaw hlawv cement rotary kiln.

Cov ntawv thov ntawm Mullite Bricks

Cov cib Mullite muaj ntau yam ua rau lawv tsis tseem ceeb rau ntau yam lag luam kub.

1. Kev Lag Luam Hlau

Kev tsim cov hlau muaj qhov kub thiab txias heev (txog li 1800 ° C) thiab cov slags corrosive. Cov cib mullite sintered kab cov qhov cub kub blast, qhov twg lawv cov thermal shock tiv thaiv kev tawg los ntawm kev cua sov / txias sai. Cov qauv fused-cast tiv thaiv cov ladles thiab tundishes, txo cov slag erosion thiab ntev lub neej ntawm cov khoom siv los ntawm 20-30% piv rau cov refractories ib txwm muaj.

2. Kev Lag Luam Cement

Cov qhov cub ua los ntawm cov cement rotary ua haujlwm ntawm 1450–1600°C, nrog rau cov alkaline slags ua rau muaj kev pheej hmoo loj ntawm kev yaig. Cov cib zircon mullite kab rau thaj chaw kub hnyiab ntawm qhov cub, tiv taus kev tawm tsam alkali thiab tswj kev ruaj khov ntawm cov qauv. Cov cib mullite sib dua kuj ua haujlwm ua cov txheej rwb thaiv tsev, txo kev siv hluav taws xob los ntawm 10–15%.

3. Kev Lag Luam Iav

Cov iav uas yaj (1500–1600°C) muaj xeb heev, ua rau cov cib mullite fused-cast tseem ceeb rau cov khoom siv rov ua dua tshiab ntawm lub cub tawg iav thiab cov ntaub thaiv lub tank. Lawv tiv thaiv kev ua qias tuaj ntawm iav thiab txuas lub sijhawm ua haujlwm ntawm lub cub tawg mus txog 5–8 xyoo, nce ntxiv los ntawm 3–5 xyoo nrog lwm cov ntaub ntawv.

4. Lwm yam lag luam

Hauv kev ua hlau uas tsis yog ferrous (txhuas, tooj liab), cov cib zircon mullite tiv taus cov hlau yaj thiab slag erosion. Hauv petrochemicals, cov cib sintered mullite kab cracking furnaces vim lawv qhov thermal stability. Hauv ceramics, cov cib mullite sib dua ua rau cov kilns rwb thaiv tsev, txo kev siv hluav taws xob.

Xaus lus

Cov cib mullite muaj ntau hom - sintered, fused-cast, lightweight, thiab zircon - ua tau raws li qhov xav tau tshwj xeeb ntawm cov lag luam kub siab. Txij li kev ua kom lub cub tawg hlau ua haujlwm tau zoo mus txog rau kev ua kom lub cub tawg iav ntev dua, lawv muab cov txiaj ntsig pom tseeb: lub neej ntev dua ntawm cov khoom siv, txo cov nqi zog, thiab txo lub sijhawm tsis ua haujlwm. Thaum cov lag luam nrhiav kev tsim khoom siab dua thiab kev ruaj khov, cov cib mullite yuav tseem yog qhov kev daws teeb meem tseem ceeb. Xaiv hom zoo rau koj daim ntawv thov, thiab qhib lawv lub peev xwm tag nrho.

Lub sijhawm tshaj tawm: Lub Kaum Hli-31-2025