Lub teeb yuag Castable

Cov ntaub ntawv khoom

| Khoom npe | Refractory Castable |

| Pawg | Tsawg cement castable / siab zog castable / High alumina castable / Lub teeb yuag castable |

| Kev sib xyaw | Refractory aggregates, hmoov thiab binders |

| Nta | 1. Kev tsim kho yooj yim 2. Zoo slag kuj 3. Zoo corrosion kuj 4. Cov hluav taws kub zoo 5. Kev txuag hluav taws xob thiab kev tiv thaiv ib puag ncig |

| Cov khoom | Tsawg Cement Castable | Siab zog Castable |

| Kev piav qhia | Tsawg cement castables xa mus rau castables tshiab nrog me ntsis cement binder.Cov ntsiab lus cement ntawm refractory castables feem ntau yog 15% mus rau 20%, thiab cov cement cov ntsiab lus ntawm cov cement castables tsawg yog li 5%, thiab qee qhov txawm txo mus rau 1% mus rau 2%. | Lub zog hnyav hnav-tiv taus castable yog tsim los ntawm lub zog loj sib sau ua ke, ntxhia cov khoom sib xyaw ua ke, siab zog sib sau ua ke thiab tiv thaiv tawg thiab hnav-tiv taus tus neeg sawv cev. |

| Nta | Thermal shock resistance, slag resistance, thiab erosion resistance yog qhov zoo dua, zoo dua li cov cib refractory. | Lub zog muaj zog, siab hnav tsis kam, cuam tshuam tsis kam, yaig tsis kam, tiv thaiv roj permeability, arbitrary zoo tswj, muaj zog ncaj ncees, kev tsim kho yooj yim, kev tsim kho zoo, thiab kev pabcuam ntev. |

| Daim ntawv thov | 1. Sab hauv ntawm ntau yam kev kho cua sov rauv, cua sov rauv, ncej kilns, rotary kilns, hluav taws xob rauv npog, blast furnace tapholes; 2. Nws tus kheej ntws qis-cement castables yog tsim rau high-temperature spray phom linings rau tshuaj tsuag metallurgy thiab petrochemical catalytic cracking reactors Hnav-resistant hauv ob sab phlu, txheej txheej ntawm cua sov rauv dej-txias yeeb nkab, thiab lwm yam. | Sab hauv hnav-resistant txheej ntawm slag sluice,ore trough, thee spout, hopper thiab silo hauv metallurgy, thee, thermal zog, tshuaj,cement thiab lwm yam kev lag luam, thiab lub tshuab hluav taws xob sib tov sib xyaw silo, sintering silo, feeder, pelletizer, thiab lwm yam. |

| Cov khoom | High Alumina Castable | Lub teeb yuag Castable |

| Kev piav qhia | High-alumina castables yog refractorycastables ua los ntawm high-alumina raw khoomas aggregates thiab hmoov, thiab ntxivnrog binders. | Lub teeb yuag castable nrog tsawg ntom ntom yog ua los ntawm aluminate cement, siab alumina zoo khoom, ceramsite, thiab additives. |

| Nta | Nws muaj lub zog txhua yam thiab zoo thermal poob siab tsis kam, abrasion tsis kam thiab lwm yam khoom. | Kev ceev qis, me thermal rwb thaiv tsev cov txiaj ntsig, kua qaub thiab rwb thaiv tsev cua sov, thiab dej kub. |

| Daim ntawv thov | Nws yog tsuas yog siv nyob rau hauv lub puab txheej ntawm boilers, moj tej tawg rauv kub moj tej tawg qhov cub, cua sov rauv, ceramic kilns thiab lwm yam kilns. | Lub teeb castable yuav siv tau rau cov thermal rwb thaiv tsev txheej ntawm high-temperature industrial furnace thiab cov cuab yeej siv rau hauv ob sab phlu ntawm ntau yam high-temperature gas pipes. |

Product Index

| Khoom npe | Lub teeb yuag Castable | ||||||

| Ua hauj lwm txwv kub | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110 ℃ Qhov ntom ntom (g / cm3) ≥ | 1.15 | 1.25 | 1.35 Nws | 1.40 Nws | 1.50 ib | ||

| Modulus ntawm Repture (MPa) ≥ | 110 ℃ × 24 teev | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100 ℃ × 3 h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400 ℃ × 3 h | - | - | 3 | 10.8 ib | 8.1 | ||

| Txias Crushing Strength (MPa) ≥ | 110 ℃ × 24 teev | 8 | 8 | 11 | 12 | 10 | |

| 1100 ℃ × 3 h | 4 | 4 | 5 | 11 | 10 | ||

| 1400 ℃ × 3 h | - | - | 15 | 22 | 14 | ||

| Permanent Linear Change(%) | 1100 ℃ × 3 h | -0.65 1000 ℃ × 3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400 ℃ × 3 h | - | - | -0.8 | -0.55 Nws | -0.45 Nws | ||

| Thermal conductivity (W/mk) | 350 ℃ | 0.18 | 0.20 ib | 0.30 Nws | 0.48 ib | 0.52 ib | |

| 700 ℃ | 0.25 | 0.25 | 0.45 ib | 0.61 ib | 0.64 ib | ||

| Al2O3 (%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Daim ntawv thov

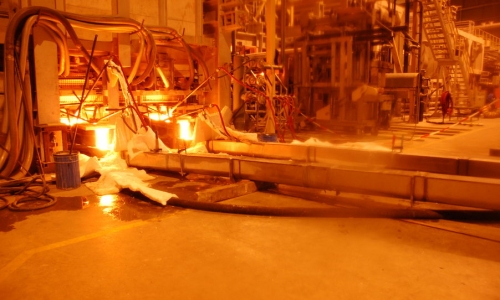

Hlau thiab steel kev lag luam:Feem ntau yog siv rau kev kho thiab patching ntawm hluav taws xob arc rauv, steelmaking furnaces, ladles thiab lwm yam khoom siv.

Non-ferrous hlau kev lag luam:Siv rau patching thiab kho cov tooj liab, txhuas, zinc, nickel thiab lwm yam uas tsis yog-ferrous hlau smelting rauv thiab converters.

Kev lag luam iav:Siv rau kev txij nkawm thiab thaj ua haujlwm ntawm iav qhov cub, annealing furnaces thiab lwm yam khoom siv.

Kev lag luam khoom siv hauv tsev: Siv rau kev tu thiab kho cov khoom siv hauv tsev xws li cement rotary kiln thiab gypsum kiln.

Kev lag luam tshuaj:Siv rau kev tu thiab kho cov khoom siv tshuaj kub kub xws li catalytic cracking furnaces thiab gasifiers.

Kev lag luam ceramic:Siv rau kev tu thiab kho cov khoom siv ceramics xws li qhov cub thiab shuttle kiln.

Pob & Warehouse

Cov lus nug nquag

Xav tau kev pab?Nco ntsoov mus saib peb lub rooj sab laj kev txhawb nqa rau cov lus teb rau koj cov lus nug!

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov ntaub ntawv refractory rau ntau tshaj 30 xyoo.Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov zoo tshaj plaws ua ntej muag thiab kev pab cuam tom qab muag.

Rau txhua tus txheej txheem tsim khoom, RBT muaj kev ua tiav QC rau cov tshuaj muaj pes tsawg leeg thiab lub cev muaj zog.Thiab peb yuav kuaj cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom.Yog tias koj muaj cov cai tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws kom haum lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv.Tab sis peb cog lus tias yuav nkoj sai li sai tau nrog lav zoo.

Tau kawg, peb muab cov qauv dawb.

Yog lawm, tau kawg, txais tos tuaj xyuas RBT tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov ntaub ntawv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb zog thiab kev nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov kilns sib txawv thiab muab kev pabcuam ib zaug.