Lub koob npe nrov Gd Hom Silicon Carbide Sic Rod Cov Khoom Siv Kub Rau Kev Lag Luam Kub Hnyiab Hluav Taws Xob

Rau qhov ua theem ntawm kev ua tiav kev npau suav ntawm peb cov neeg ua haujlwm! Txhawm rau tsim kom muaj kev zoo siab dua, sib koom siab dua thiab ntau tus kws tshaj lij dua! Txhawm rau kom tau txais txiaj ntsig ntawm peb cov neeg siv khoom, cov neeg muag khoom, lub zej zog thiab peb tus kheej rau Lub koob npe nrov Gd Hom Silicon Carbide Sic Rod Heating Elements rau Kev Lag Luam Kub Siab Hluav Taws Xob, Peb txais tos cov neeg yuav khoom thoob plaws lub ntiaj teb los tiv tauj peb rau kev koom tes ua lag luam me yav tom ntej. Peb cov khoom thiab cov kev daws teeb meem yog qhov zoo tshaj plaws. Thaum Xaiv, Zoo Tag Nrho Mus Ib Txhis!

Rau qhov ua lub theem ntawm kev ua tiav cov kev npau suav ntawm peb cov neeg ua haujlwm! Los tsim kom muaj kev zoo siab dua, sib koom siab dua thiab muaj kev txawj ntse ntau dua! Txhawm rau kom tau txais txiaj ntsig sib koom siab ntawm peb cov neeg siv khoom, cov neeg muag khoom, lub zej zog thiab peb tus kheej rauTuam Tshoj Silicon Carbide Qws thiab Silicon Carbide Cua Sov Qws, Nrog cov khoom lag luam zoo tshaj plaws, kev pabcuam tom qab muag zoo thiab txoj cai lav, peb yeej kev ntseeg siab los ntawm ntau tus khub txawv teb chaws, ntau cov lus tawm tswv yim zoo tau pom peb lub Hoobkas loj hlob. Nrog kev ntseeg siab thiab lub zog tag nrho, txais tos cov neeg siv khoom tiv tauj thiab tuaj xyuas peb rau kev sib raug zoo yav tom ntej.

Cov Ntaub Ntawv Khoom

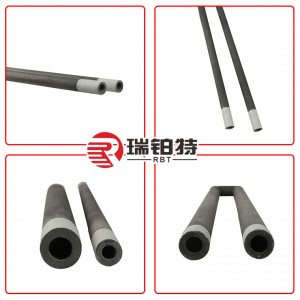

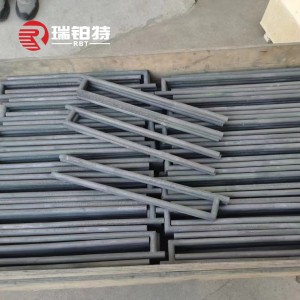

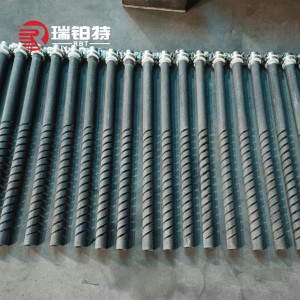

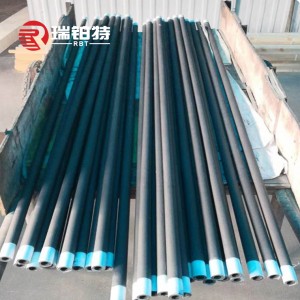

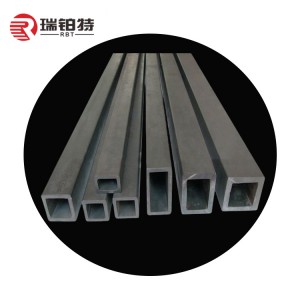

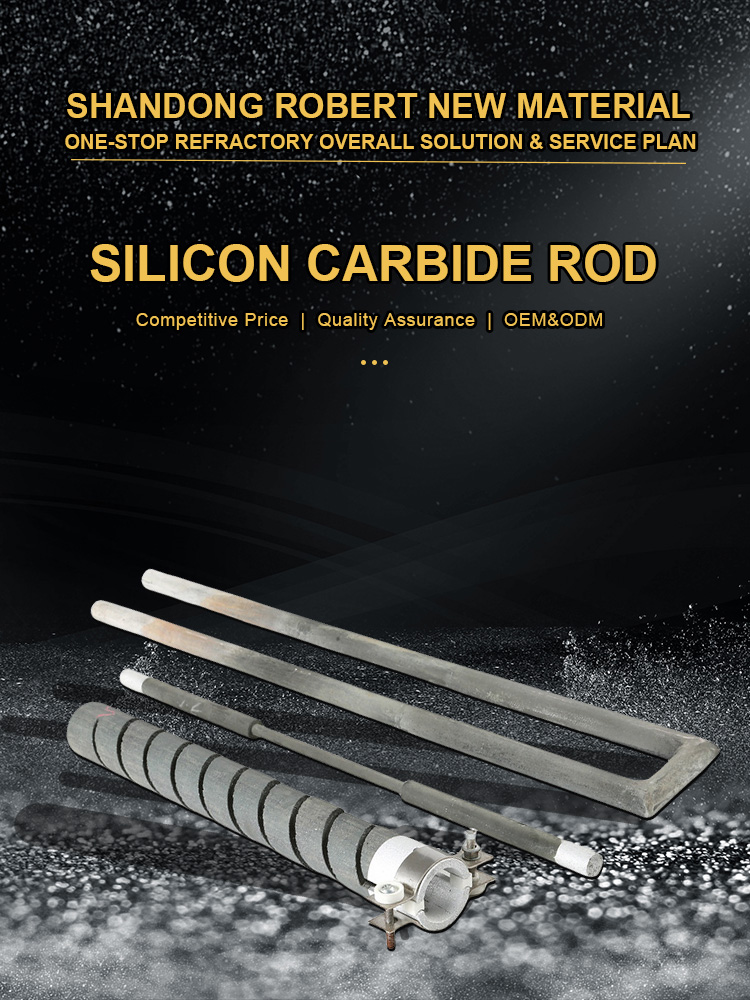

Cov pas nrig silicon carbideyog cov pas nrig thiab tubular tsis yog hlau kub kub hluav taws xob ua los ntawm cov khoom siv siab-purity ntsuab hexagonal silicon carbide ua cov khoom siv raw tseem ceeb, ua tiav rau hauv cov khoom seem raws li qee qhov piv ntawm cov khoom siv, thiab sintered ntawm 2200 ° C rau kev kub siab siliconization, recrystallization thiab sintering.

Qhov kub siv ib txwm nyob rau hauv ib qho chaw oxidizing tuaj yeem ncav cuag 1450 ° C, thiab kev siv tas mus li tuaj yeem ncav cuag 2000 teev.

Cov yam ntxwv

1. Kev kub siab tsis kam

2. Kev tiv thaiv oxidation

3. Kev tiv thaiv xeb

4. Cua sov sai

5. Lub neej ntev

6. Kev hloov pauv me me ntawm qhov kub siab

7. Kev teeb tsa yooj yim thiab kev txij nkawm

Cov Duab Qhia Txog

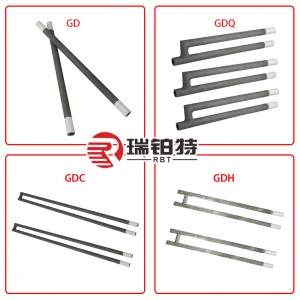

| Qauv | GD (Tus pas nrig sib npaug); GC (Tus pas nrig kawg); GDC (Tus pas nrig U-puab); GDQ (Tus pas nrig hom phom); GDH (Tus pas nrig hom H); Tus pas nrig me me; Tus pas nrig kev cai |

Cov nyhuv zaub

Daim Ntawv Thov

Siv dav hauv cov teb kub xws li electronics, magnetic materials, hmoov metallurgy, ceramics, iav, semiconductors, kev tshuaj xyuas thiab kev sim, thiab kev tshawb fawb, thiab tau dhau los ua qhov cub qhov av, qhov cub roller, qhov cub iav, qhov cub nqus tsev, qhov cub muffle, qhov cub smelting thiab cov khoom siv hluav taws xob rau cov khoom siv cua sov.

Cov Ntaub Ntawv Txog Lub Tuam Txhab

Shandong Robert New Material Co., Ltd.nyob hauv Zibo City, Shandong xeev, Suav teb, uas yog lub hauv paus tsim cov khoom siv refractory. Peb yog ib lub tuam txhab niaj hnub uas koom ua ke kev tshawb fawb thiab kev txhim kho, kev tsim khoom, kev muag khoom, kev tsim kho qhov cub, thev naus laus zis, thiab kev xa tawm cov khoom siv refractory. Peb muaj cov khoom siv tiav, thev naus laus zis siab heev, lub zog muaj zog, cov khoom zoo heev, thiab lub koob npe zoo. Peb lub Hoobkas npog ntau dua 200 daim av thiab cov khoom tsim tawm txhua xyoo yog kwv yees li 30000 tons thiab cov khoom siv refractory tsis muaj duab yog 12000 tons.

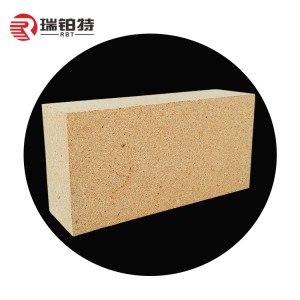

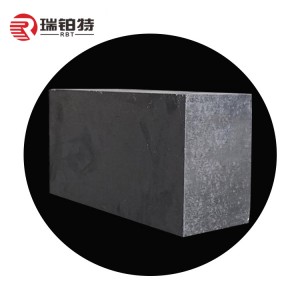

Peb cov khoom tseem ceeb ntawm cov ntaub ntawv refractory suav nrog:Cov ntaub ntawv alkaline refractory; cov ntaub ntawv aluminium silicon refractory; cov ntaub ntawv refractory tsis muaj duab; cov ntaub ntawv thermal refractory rwb thaiv tsev; cov ntaub ntawv refractory tshwj xeeb; cov ntaub ntawv refractory ua haujlwm rau cov txheej txheem casting tas mus li.

Cov khoom Robert siv dav hauv cov qhov cub kub siab xws li cov hlau tsis yog ferrous, hlau, cov ntaub ntawv siv hauv tsev thiab kev tsim kho, tshuaj lom neeg, hluav taws xob, kev hlawv pov tseg, thiab kev kho cov khib nyiab phom sij. Lawv kuj siv rau hauv cov hlau thiab hlau xws li ladles, EAF, lub cub tawg, converters, coke ovens, lub cub tawg kub; cov qhov cub metallurgical tsis yog ferrous xws li reverberators, txo qhov cub, lub cub tawg, thiab rotary kilns; cov khoom siv hauv tsev xws li iav kilns, cement kilns, thiab ceramic kilns; lwm cov qhov cub xws li boilers, pov tseg incinerators, roasting furnace, uas tau ua tiav cov txiaj ntsig zoo hauv kev siv. Peb cov khoom raug xa tawm mus rau Southeast Asia, Central Asia, Middle East, Africa, Europe, Americas thiab lwm lub tebchaws, thiab tau tsim kom muaj kev koom tes zoo nrog ntau lub tuam txhab hlau paub zoo. Txhua tus neeg ua haujlwm ntawm Robert zoo siab tos ntsoov yuav ua haujlwm nrog koj rau qhov xwm txheej yeej-yeej.

Cov Lus Nug Feem Ntau

Xav tau kev pab? Nco ntsoov mus saib peb cov rooj sib tham txhawb nqa kom tau cov lus teb rau koj cov lus nug!

Koj puas yog ib lub chaw tsim khoom lossis ib tus tub luam?

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov khoom siv refractory rau ntau tshaj 30 xyoo. Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov kev pabcuam ua ntej muag thiab tom qab muag zoo tshaj plaws.

Koj tswj koj qhov zoo li cas?

Rau txhua txoj kev tsim khoom, RBT muaj lub kaw lus QC tiav rau cov tshuaj lom neeg thiab cov khoom siv lub cev. Thiab peb yuav sim cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom. Yog tias koj muaj cov kev xav tau tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws los pab txhawb lawv.

Koj lub sijhawm xa khoom yog dab tsi?

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv. Tab sis peb cog lus tias yuav xa khoom sai li sai tau nrog kev lees paub zoo.

Koj puas muab cov qauv dawb?

Tau kawg, peb muab cov qauv dawb.

Peb puas tuaj yeem mus xyuas koj lub tuam txhab?

Yog, tau kawg, koj tuaj yeem mus xyuas RBT lub tuam txhab thiab peb cov khoom.

MOQ rau kev txiav txim mus sib hais yog dab tsi?

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Vim li cas ho xaiv peb?

Peb tau ua cov khoom siv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb nqa kev txawj ntse thiab kev paub nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov cub tawg sib txawv thiab muab kev pabcuam ib zaug.

Rau qhov ua theem ntawm kev ua tiav kev npau suav ntawm peb cov neeg ua haujlwm! Txhawm rau tsim kom muaj kev zoo siab dua, sib koom siab dua thiab ntau tus kws tshaj lij dua! Txhawm rau kom tau txais txiaj ntsig ntawm peb cov neeg siv khoom, cov neeg muag khoom, lub zej zog thiab peb tus kheej rau Lub koob npe nrov Gd Hom Silicon Carbide Sic Rod Heating Elements rau Kev Lag Luam Kub Siab Hluav Taws Xob, Peb txais tos cov neeg yuav khoom thoob plaws lub ntiaj teb los tiv tauj peb rau kev koom tes ua lag luam me yav tom ntej. Peb cov khoom thiab cov kev daws teeb meem yog qhov zoo tshaj plaws. Thaum Xaiv, Zoo Tag Nrho Mus Ib Txhis!

Lub koob npe nrovTuam Tshoj Silicon Carbide Qws thiab Silicon Carbide Cua Sov Qws, Nrog cov khoom lag luam zoo tshaj plaws, kev pabcuam tom qab muag zoo thiab txoj cai lav, peb yeej kev ntseeg siab los ntawm ntau tus khub txawv teb chaws, ntau cov lus tawm tswv yim zoo tau pom peb lub Hoobkas loj hlob. Nrog kev ntseeg siab thiab lub zog tag nrho, txais tos cov neeg siv khoom tiv tauj thiab tuaj xyuas peb rau kev sib raug zoo yav tom ntej.