Lim ua npuas ncauj ua los ntawm cov khoom siv ceramic

Kev piav qhia txog khoom

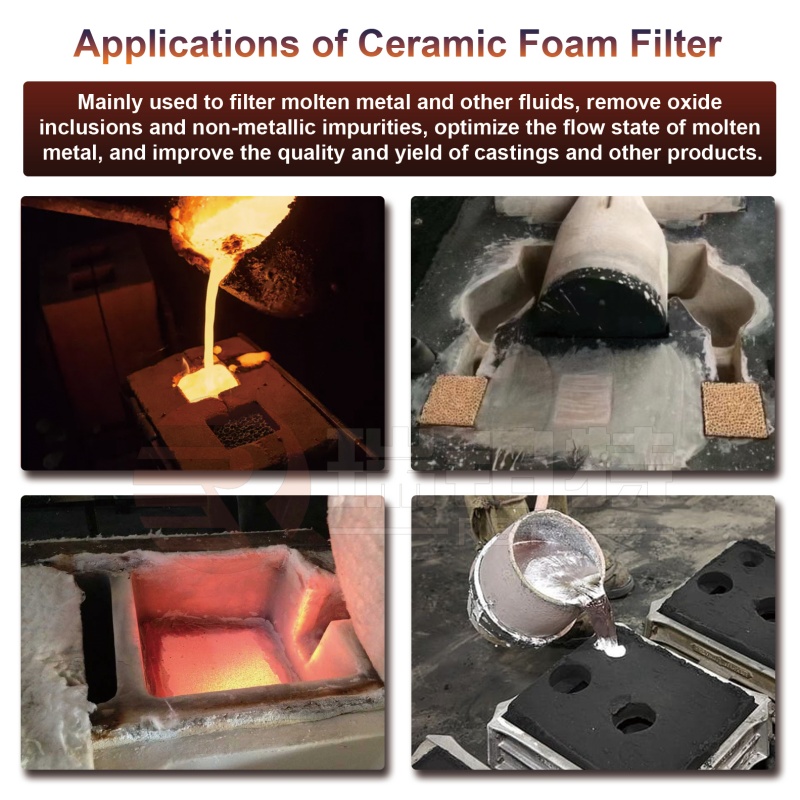

Cov lim dej ua npuas ncaujyog ib hom khoom siv tshiab siv los lim cov kua xws li cov hlau uas yaj. Nws muaj cov qauv tshwj xeeb thiab kev ua tau zoo heev thiab siv dav hauv kev lag luam xws li kev casting.

1. Alumina:

Kub siv tau: 1250 ℃. Haum rau kev lim thiab ntxuav cov txhuas thiab cov hlau sib xyaw. Siv dav hauv kev xuab zeb casting thiab pwm tas mus li xws li kev casting qhov chaw txhuas hauv tsheb.

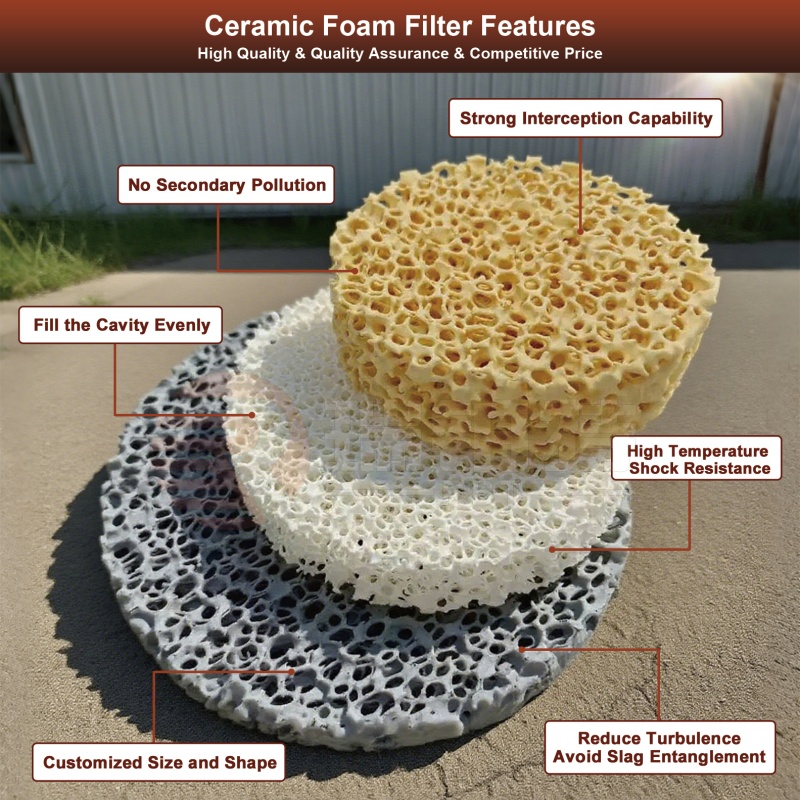

Cov txiaj ntsig:

(1) Tshem tawm cov khoom tsis huv kom zoo.

(2) Cov dej ntws ruaj khov Molten aluminium thiab yooj yim rau kev sau.

(3) Txo qhov tsis zoo ntawm casting, txhim kho qhov zoo ntawm qhov chaw thiab cov khoom.

2. SIC

Nws muaj lub zog zoo heev thiab tiv taus kev kub hnyiab thiab kev xeb ntawm cov tshuaj lom neeg, thiab tuaj yeem tiv taus qhov kub siab txog li 1560 ° C. Nws yog qhov tsim nyog rau kev casting tooj liab alloys thiab cam khwb cia hlau.

Cov txiaj ntsig:

(1) Tshem tawm cov khoom tsis huv thiab txhim kho qhov huv ntawm cov hlau molten kom zoo.

(2) Txo qhov turbulence thiab txawm tias filling.

(3) Txhim kho qhov zoo ntawm qhov chaw casting thiab cov txiaj ntsig, txo qhov kev pheej hmoo ntawm qhov tsis zoo.

3. Zirconia

Qhov kub uas tiv taus cua sov siab dua li ntawm 1760 ℃, nrog lub zog siab thiab kev cuam tshuam zoo thaum kub siab. Nws tuaj yeem tshem tawm cov khoom tsis huv hauv cov hlau castings thiab txhim kho qhov zoo ntawm qhov chaw thiab cov khoom siv kho tshuab ntawm cov castings.

Cov txiaj ntsig:

(1) Txo cov khoom me me uas tsis huv.

(2) Txo qhov tsis zoo ntawm qhov chaw, txhim kho qhov zoo ntawm qhov chaw.

(3) Txo kev sib tsoo, txo qis machining nqi.

4. Kev sib txuas ua ke raws li cov pa roj carbon

Tsim tshwj xeeb rau cov hlau carbon thiab cov hlau tsis muaj hlau ntau, lub lim dej ua los ntawm cov khoom siv ...

kev kub ntxhov.

Cov txiaj ntsig:

(1) Qhov ntom ntom tsawg, qhov hnyav tsawg heev thiab qhov hnyav thermal, ua rau muaj qhov coefficient cia cua sov tsawg heev. Qhov no tiv thaiv cov hlau yaj pib kom khov hauv lub lim thiab ua kom cov hlau hla dhau lub lim sai sai. Kev sau lub lim tam sim ntawd pab txo qhov kev ntxhov siab los ntawm kev suav nrog thiab slag.

(2) Cov txheej txheem siv tau dav, suav nrog xuab zeb, plhaub, thiab precision ceramic casting.

(3) Qhov kub siab tshaj plaws ua haujlwm ntawm 1650 ° C, ua rau cov txheej txheem nchuav ib txwm yooj yim dua.

(4) Cov qauv mesh peb-seem tshwj xeeb tswj tau qhov ntws ntawm cov hlau turbulent, ua rau muaj kev faib tawm microstructure hauv qhov casting.

(5) Ua kom zoo lim cov khoom me me uas tsis yog hlau, txhim kho kev siv tshuab ntawm cov khoom.

(6) Txhim kho cov khoom siv kho tshuab ntawm qhov casting, suav nrog qhov nyuaj ntawm qhov chaw, lub zog tensile, kev tiv taus qaug zog, thiab elongation.

(7) Tsis muaj kev cuam tshuam tsis zoo rau kev rov ua dua ntawm cov khoom siv lim dej uas muaj cov khoom siv lim.

Cov Khoom Muag

| Cov Qauv thiab Cov Kev Ntsuas ntawm Alumina Ceramic Foam Filters | |||||

| Khoom | Lub Zog Nqus (MPa) | Qhov porosity (%) | Qhov Ceev Ntau (g/cm3) | Kub Ua Haujlwm (≤ ℃) | Cov ntawv thov |

| RBT-01 | ≥0.8 | 80-90 | 0.35-0.55 | 1200 | Kev Sib Tsoo Aluminium Alloy |

| RBT-01B | ≥0.4 | 80-90 | 0.35-0.55 | 1200 | Kev Ua Txhuas Loj |

| Qhov Loj thiab Peev Xwm ntawm Alumina Ceramic Foam Filters | ||||

| Loj (hli) | Qhov hnyav (kg) | Tus Nqi Nqus (kg / s) | Qhov hnyav (kg) | Tus Nqi Nqus (kg / s) |

| 10ppi | 20ppi | |||

| 50 * 50 * 22 | 42 | 2 | 30 | 1.5 |

| 75 * 75 * 22 | 96 | 5 | 67 | 4 |

| 100 * 100 * 22 | 170 | 9 | 120 | 7 |

| φ50 * 22 | 33 | 1.5 | 24 | 1.5 |

| φ75 * 22 | 75 | 4 | 53 | 3 |

| φ90 * 22 | 107 | 5 | 77 | 4.5 |

| Loj (Nti) | Qhov hnyav (Ton) 20,30,40ppi | Tus Nqi Nqus (kg / min) | ||

| 7"*7"*2" | 4.2 | 25-50 | ||

| 9"*9"*2" | 6 | 25-75 | ||

| 10"*10"*2" | 6.9 | 45-100 | ||

| 12"*12"*2" | 13.5 | 90-170 | ||

| 15"*15"*2" | 23.2 | 130-280 | ||

| 17"*17"*2" | 34.5 | 180-370 | ||

| 20"*20"*2" | 43.7 | 270-520 | ||

| 30"*23"*2" | 57.3 | 360-700 | ||

| Cov Qauv thiab Cov Kev Ntsuas ntawm SIC Ceramic Foam Filters | |||||

| Khoom | Lub Zog Nqus (MPa) | Qhov porosity (%) | Qhov Ceev Ntau (g/cm3) | Kub Ua Haujlwm (≤ ℃) | Cov ntawv thov |

| RBT-0201 | ≥1.2 | ≥80 | 0.40-0.55 | 1480 xyoo | Hlau zas, hlau grey thiab hlau tsis yog ferrous |

| RBT-0202 | ≥1.5 | ≥80 | 0.35-0.60 | 1500 xyoo | Rau kev pouncing ncaj qha thiab cov hlau loj castings |

| RBT-0203 | ≥1.8 | ≥80 | 0.47-0.55 | 1480 xyoo | Rau cov cua turbine thiab cov castings loj |

| Qhov Loj thiab Peev Xwm ntawm SIC Ceramic Foam Filters | ||||||||

| Loj (hli) | 10ppi | 20ppi | ||||||

| Qhov hnyav (kg) | Tus Nqi Nqus (kg / s) | Qhov hnyav (kg) | Tus Nqi Nqus (kg / s) | |||||

| Xim av Hlau | Hlau Ductile | Hlau Grey | Hlau Ductile | Hlau Grey | Hlau Ductile | Hlau Grey | Hlau Ductile | |

| 40 * 40 * 15 | 40 | 22 | 3.1 | 2.3 | 35 | 18 | 2.9 | 2.2 |

| 40 * 40 * 22 | 64 | 32 | 4 | 3 | 50 | 25 | 3.2 | 2.5 |

| 50 * 30 * 22 | 60 | 30 | 4 | 3 | 48 | 24 | 3.5 | 2.5 |

| 50 * 50 * 15 | 50 | 30 | 3.5 | 2.6 | 45 | 26 | 3.2 | 2.5 |

| 50 * 50 * 22 | 100 | 50 | 6 | 4 | 80 | 40 | 5 | 3 |

| 75 * 50 * 22 | 150 | 75 | 9 | 6 | 120 | 60 | 7 | 5 |

| 75 * 75 * 22 | 220 | 110 | 14 | 9 | 176 | 88 | 11 | 7 |

| 100 * 50 * 22 | 200 | 100 | 12 | 8 | 160 | 80 | 10 | 6.5 |

| 100 * 100 * 22 | 400 | 200 | 24 | 15 | 320 | 160 | 19 | 12 |

| 150 * 150 * 22 | 900 | 450 | 50 | 36 | 720 | 360 | 40 | 30 |

| 150 * 150 * 40 | 850-1000 | 650-850 | 52-65 | 54-70 | _ | _ | _ | _ |

| 300 * 150 * 40 | 1200-1500 | 1000-1300 | 75-95 | 77-100 | _ | _ | _ | _ |

| φ50 * 22 | 80 | 40 | 5 | 4 | 64 | 32 | 4 | 3.2 |

| φ60 * 22 | 110 | 55 | 6 | 5 | 88 | 44 | 4.8 | 4 |

| φ75 * 22 | 176 | 88 | 11 | 7 | 140 | 70 | 8.8 | 5.6 |

| φ80 * 22 | 200 | 100 | 12 | 8 | 160 | 80 | 9.6 | 6.4 |

| φ90 * 22 | 240 | 120 | 16 | 10 | 190 | 96 | 9.6 | 8 |

| φ100 * 22 | 314 | 157 | 19 | 12 | 252 | 126 | 15.2 | 9.6 |

| φ125 * 25 | 400 | 220 | 28 | 18 | 320 | 176 | 22.4 | 14.4 |

| Cov Qauv thiab Cov Kev Ntsuas ntawm Zirconia Ceramic Foam Filters | |||||

| Khoom | Lub Zog Nqus (MPa) | Qhov porosity (%) | Qhov Ceev Ntau (g/cm3) | Kub Ua Haujlwm (≤ ℃) | Cov ntawv thov |

| RBT-03 | ≥2.0 | ≥80 | 0.75-1.00 | 1700 xyoo | Rau cov hlau tsis xeb, cov hlau carbon thiab cov hlau castings loj loj |

| Qhov Loj thiab Peev Xwm ntawm Zirconia Ceramic Foam Filters | |||

| Loj (hli) | Tus Nqi Nqus (kg / s) | Peev Xwm (kg) | |

| Cov Hlau Carbon | Cov Hlau Sib Xyaws | ||

| 50 * 50 * 22 | 2 | 3 | 55 |

| 50 * 50 * 25 | 2 | 3 | 55 |

| 55 * 55 * 25 | 4 | 5 | 75 |

| 60 * 60 * 22 | 3 | 4 | 80 |

| 60 * 60 * 25 | 4.5 | 5.5 | 86 |

| 66 * 66 * 22 | 3.5 | 5 | 97 |

| 75 * 75 * 25 | 4.5 | 7 | 120 |

| 100 * 100 * 25 | 8 | 10.5 | 220 |

| 125 * 125 * 30 | 18 | 20 | 375 |

| 150 * 150 * 30 | 18 | 23 | 490 |

| 200 * 200 * 35 | 48 | 53 | 960 |

| φ50 * 22 | 1.5 | 2.5 | 50 |

| φ50 * 25 | 1.5 | 2.5 | 50 |

| φ60 * 22 | 2 | 3.5 | 70 |

| φ60 * 25 | 2 | 3.5 | 70 |

| φ70 * 25 | 3 | 4.5 | 90 |

| φ75 * 25 | 3.5 | 5.5 | 110 |

| φ90 * 25 | 5 | 7.5 | 150 |

| φ100 * 25 | 6.5 | 9.5 | 180 |

| φ125 * 30 | 10 | 13 | 280 |

| φ150 * 30 | 13 | 17 | 400 |

| φ200 * 35 | 26 | 33 | 720 |

| Cov Qauv thiab Cov Kev Ntsuas ntawm Cov Pa roj carbon-based Bonding Ceramic Foam Filters | |||||

| Khoom | Lub Zog Nqus (MPa) | Qhov porosity (%) | Qhov Ceev Ntau (g/cm3) | Kub Ua Haujlwm (≤ ℃) | Cov ntawv thov |

| RBT-Carbon | ≥1.0 | ≥76 | 0.4-0.55 | 1650 xyoo | Cov hlau carbon, cov hlau tsis tshua muaj hlau, cov hlau loj castings. |

| Qhov Loj ntawm Cov Pa roj carbon-based Bonding Ceramic Foam Filters | |

| 50 * 50 * 22 10 / 20ppi | φ50 * 22 10/20ppi |

| 55 * 55 * 25 10 / 20ppi | φ50 * 25 10/20ppi |

| 75 * 75 * 22 10 / 20ppi | φ60 * 25 10/20ppi |

| 75 * 75 * 25 10 / 20ppi | φ70 * 25 10/20ppi |

| 80 * 80 * 25 10/20ppi | φ75 * 25 10/20ppi |

| 90 * 90 * 25 10/20ppi | φ80 * 25 10/20ppi |

| 100 * 100 * 25 10/20ppi | φ90 * 25 10/20ppi |

| 125 * 125 * 30 10 / 20ppi | φ100 * 25 10/20ppi |

| 150 * 150 * 30 10 / 20ppi | φ125 * 30 10/20ppi |

| 175 * 175 * 30 10 / 20ppi | φ150 * 30 10/20ppi |

| 200 * 200 * 35 10 / 20ppi | φ200 * 35 10/20ppi |

| 250 * 250 * 35 10 / 20ppi | φ250 * 35 10/20ppi |

Cov Ntaub Ntawv Txog Lub Tuam Txhab

Shandong Robert New Material Co., Ltd.nyob hauv Zibo City, Shandong xeev, Suav teb, uas yog lub hauv paus tsim cov khoom siv refractory. Peb yog ib lub tuam txhab niaj hnub uas koom ua ke kev tshawb fawb thiab kev txhim kho, kev tsim khoom, kev muag khoom, kev tsim kho qhov cub, thev naus laus zis, thiab kev xa tawm cov khoom siv refractory. Peb muaj cov khoom siv tiav, thev naus laus zis siab heev, lub zog muaj zog, cov khoom zoo heev, thiab lub koob npe zoo. Peb lub Hoobkas npog ntau dua 200 daim av thiab cov khoom tsim tawm txhua xyoo yog kwv yees li 30000 tons thiab cov khoom siv refractory tsis muaj duab yog 12000 tons.

Peb cov khoom tseem ceeb ntawm cov ntaub ntawv refractory suav nrog:Cov ntaub ntawv alkaline refractory; cov ntaub ntawv aluminium silicon refractory; cov ntaub ntawv refractory tsis muaj duab; cov ntaub ntawv thermal refractory rwb thaiv tsev; cov ntaub ntawv refractory tshwj xeeb; cov ntaub ntawv refractory ua haujlwm rau cov txheej txheem casting tas mus li.

Cov Lus Nug Feem Ntau

Xav tau kev pab? Nco ntsoov mus saib peb cov rooj sib tham txhawb nqa kom tau cov lus teb rau koj cov lus nug!

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov khoom siv refractory rau ntau tshaj 30 xyoo. Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov kev pabcuam ua ntej muag thiab tom qab muag zoo tshaj plaws.

Rau txhua txoj kev tsim khoom, RBT muaj lub kaw lus QC tiav rau cov tshuaj lom neeg thiab cov khoom siv lub cev. Thiab peb yuav sim cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom. Yog tias koj muaj cov kev xav tau tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws los pab txhawb lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv. Tab sis peb cog lus tias yuav xa khoom sai li sai tau nrog kev lees paub zoo.

Tau kawg, peb muab cov qauv dawb.

Yog, tau kawg, koj tuaj yeem mus xyuas RBT lub tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov khoom siv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb nqa kev txawj ntse thiab kev paub nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov cub tawg sib txawv thiab muab kev pabcuam ib zaug.