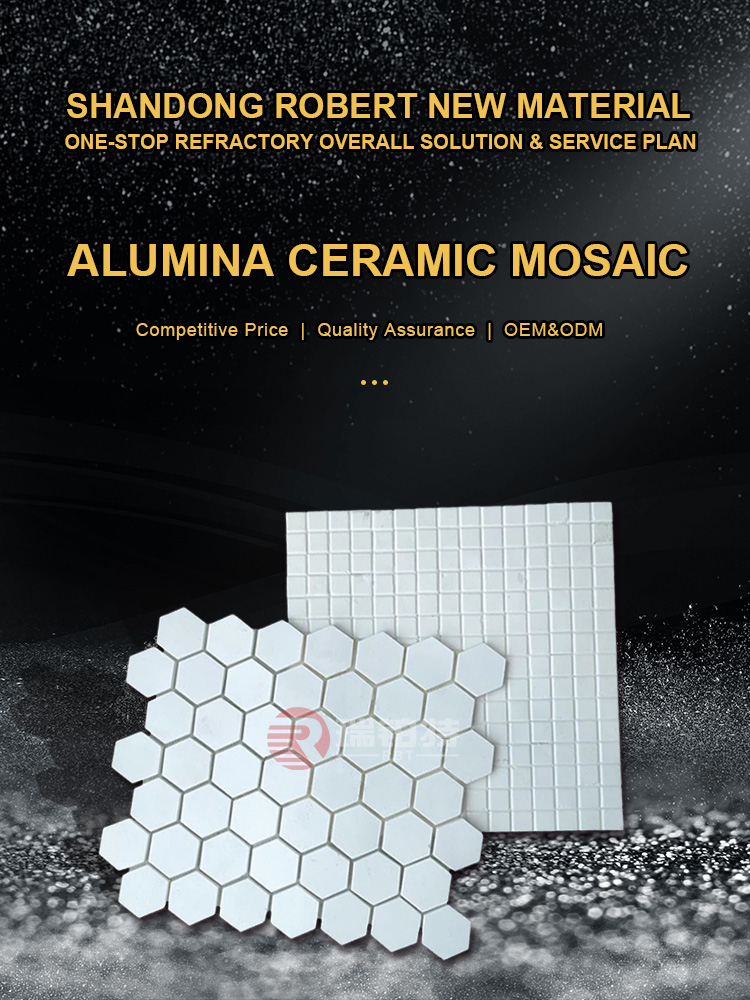

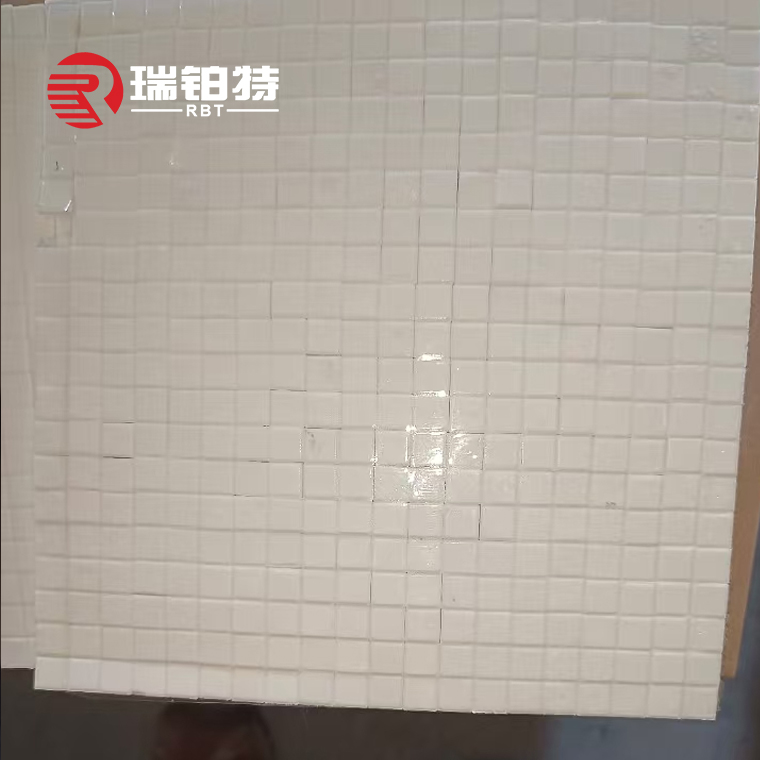

Alumina Ceramic Mosaic Vuas

Product Description

Alumina ceramic mosaicyog ib qho hnav-resistant ceramic khoom ua los ntawm alumina raws li cov khoom siv tseem ceeb, los ntawm kev kub siab molding thiab high-temperature sintering. Nws lub ntsiab tivthaiv yog alumina, thiab tsawg hlau oxides ntxiv raws li flux, thiab nws yog sintered ntawm ib tug kub ntawm 1,700 degrees.

Nta:

High hardness:Rockwell hardness ntawm alumina ceramic mosaic ncav cuag HRA80-90, thib ob tsuas yog pob zeb diamond, deb tshaj qhov hnav tsis kam ntawm cov hlau tsis muaj steel thiab stainless hlau. cov

Muaj zog hnav tsis kam:Nws hnav tsis kam yog sib npaug rau 266 npaug ntawm cov hlau manganese thiab 171.5 npaug ntawm cov chromium cam khwb cia hlau, thiab nws tuaj yeem ua tau zoo nyob rau hauv lub sijhawm siv ntau zaus. cov

Corrosion kuj:Nws tuaj yeem tiv taus qhov yaig ntawm cov xov xwm corrosive heev xws li acids, alkalis, thiab ntsev, thiab tswj kev ua haujlwm ruaj khov thiab kev ua haujlwm ruaj khov. cov

Kub kub kuj:Nws tuaj yeem nyob ruaj khov hauv qhov kub thiab txias yam tsis muaj deformation lossis melting. cov

Lub teeb yuag:Qhov ceev yog 3.6g / cm³, uas tsuas yog ib nrab ntawm cov hlau, uas tuaj yeem txo cov khoom thauj khoom.

Cov duab ntxaws

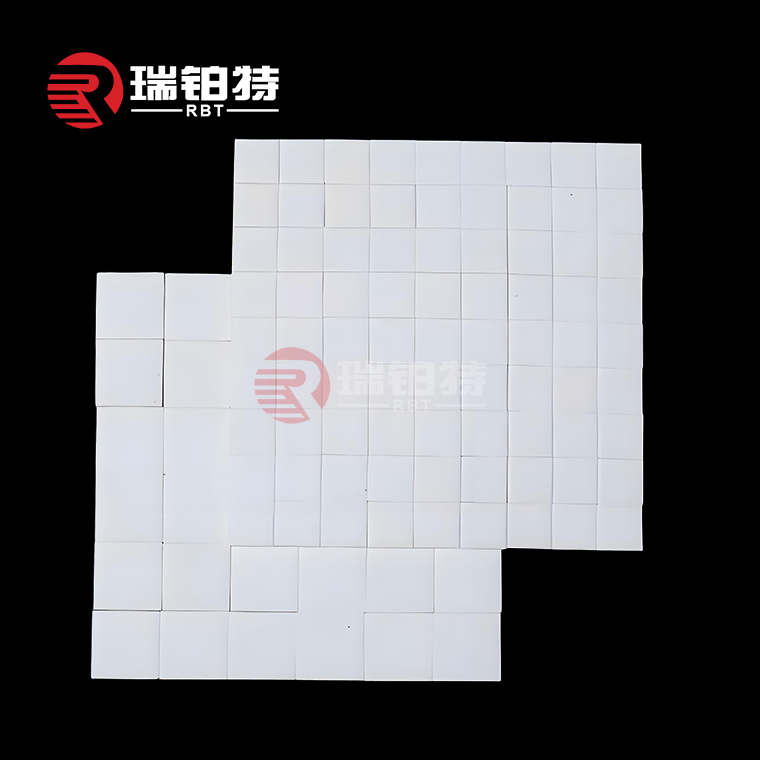

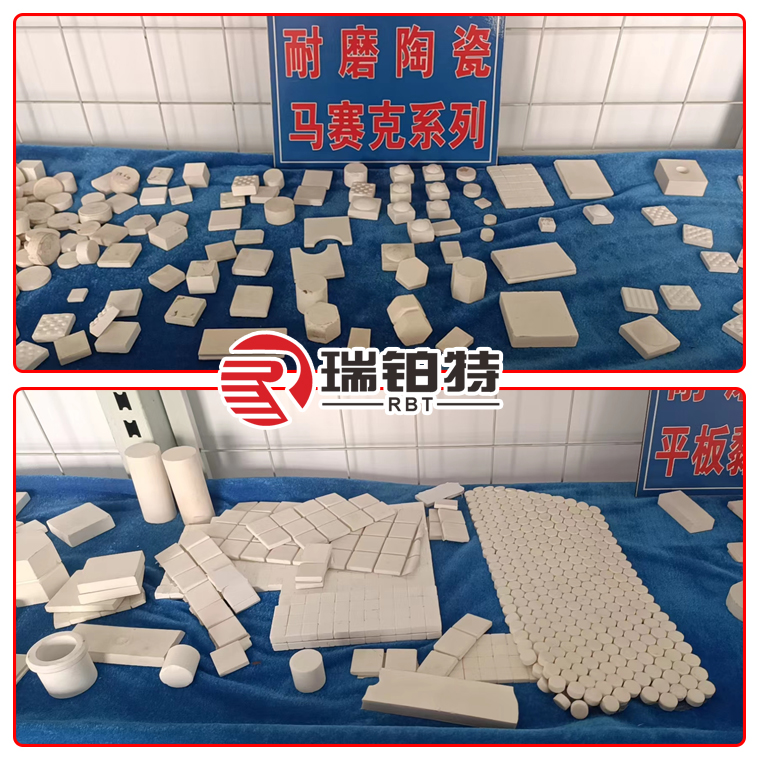

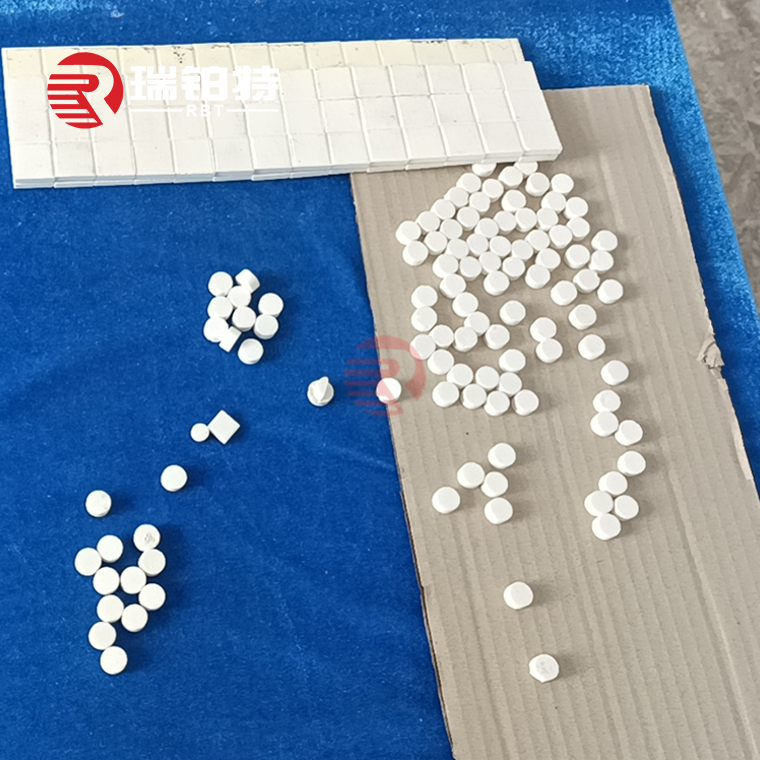

Cov duab ntawm alumina ceramic mosaics feem ntau suav nrogsquare, lub voj voog thiab hexagon. Cov qauv tsim ntawm cov duab no ua rau cov mosaic hnav-resistant ceramics kom tau raws li qhov xav tau ntawm ntau yam khoom siv tshwj xeeb zoo li tus qauv. Los ntawm kev tsim lub tswv yim ntawm kev ncaj es tsis txhob nkhaus, nws tuaj yeem ua tau zoo dua nrog lub plhaub sab hauv ntawm cov khoom siv, ua tiav gapless haum, thiab ua tau raws li qhov yuav tsum tau ua ntawm kev hnav tsis kam hauv kev tsim khoom.

Product Index

| Yam khoom | Al2O3 txog 92% | ≥ 95% | ≥ 99% | ≥ 99.5% | ≥ 99.7% |

| Xim | Dawb | Dawb | Dawb | Xim Xim | Xim Xim |

| Theoretical ntom (g / cm3) | 3.45 Nws | 3.50 Nws | 3.75 ib | 3.90 ib | 3.92 ib |

| Bending zog (Mpa) | 340 | 300 | 330 | 390 | 390 |

| Compressive zog (Mpa) | 3600 ib | 3400 ib | 2800 | 3900 ib | 3900 ib |

| Elastic Modulus (Gpa) | 350 | 350 | 370 | 390 | 390 |

| Impact Resistance (Mpam 1/2) | 4.2 | 4 | 4.4 | 5.2 | 5.5 |

| Weibull Coefficient (m) | 11 | 10 | 10 | 12 | 12 |

| Vickers Hardness (HV 0.5) | 1700 | 1800 | 1800 | 2000 | 2000 |

| Thermal Expansion Coefficient | 5.0-8.3 | 5.0-8.3 | 5.1-8.3 | 5.5-8.4 | 5.5-8.5 |

| Thermal conductivity (W / mk) | 18 | 24 | 25 | 28 | 30 |

| Thermal Shock Stability | 220 | 250 | 250 | 280 | 280 |

| Ua haujlwm kub siab tshaj ℃ | 1500 | 1600 | 1600 | 1700 | 1700 |

| 20 ℃ Volume Resistance | > 10^14 | > 10^14 | > 10^14 | > 10^15 | > 10^15 |

| Dielectric zog (kv / mm) | 20 | 20 | 20 | 30 | 30 |

| Dielectric tsis tu ncua | 10 | 10 | 10 | 10 | 10 |

Qhov Loj

| 10 * 1.5 hli | 12 * 12 * 3 | Loj: 17.5 * 17.5 * 3 | 20 * 20 * 3 | 25 * 25 * 3 |

| 10 * 10 * 3 | 12 * 12 * 4 | 17.5 * 17.5 * 4.5 hli | 20 * 20 * 4 | 25 * 25 * 5 |

| 10 * 10 * 4 | 12 * 12 * 5 | 17.5 * 17.5 * 5.5 hli | 20 * 20 * 5 | 25 * 25 * 8 |

| 10 * 10 * 5 | 12 * 12 * 6 | Loj: 17.5 * 17.5 * 6 | 20 * 20 * 6 | 25 * 25 * 10 |

| 10 * 10 * 8 | 12 * 12 * 8 | 17.5 * 17.5 * 8.5 hli | 20 * 20 * 8 | 25 * 25 * 12 |

| Loj: 10 * 10 | 12 * 12 * 10 | 17.5 * 17.5 * 10.5 hli | 20 * 20 * 10 | 25 * 25 * 15 |

Cov lus qhia saum toj no feem ntau siv los ntawm peb lub tuam txhab. Yog tias koj xav tau lwm yam tshwj xeeb, thov sab laj nrog cov neeg siv khoom. Lub tuam txhab tuaj yeem muab kev kho kom haum.

Daim ntawv thov

Daim ntawv thov kev lag luam:Dav siv nyob rau hauv cov thee tsheb thauj mus los, cov khoom conveying tshuab, hmoov ua tshuab, tshauv tshem tawm, plua plav tshem tawm tshuab, thiab lwm yam nyob rau hauv thermal zog, steel, smelting, machinery, thee, mining, tshuaj, cement, chaw nres nkoj terminals thiab lwm yam lag luam.

Petrochemical:Siv rau hauv ob sab phlu thiab hnav-resistant qhov chaw ntawm cov khoom siv xws li reactors, pipelines, twj tso kua mis lub cev, thiab lwm yam., ho expanding lub neej ntawm cov khoom thiab txhim kho kev ruaj ntseg.

Mining thiab metallurgy:Siv nyob rau hauv hnav cov khoom siv xws li pob zeb, thee mills, thiab pulping tshuab los txhim kho hnav tsis kam thiab kev ua haujlwm ntau lawm. Kev lag luam hluav taws xob: Siv rau hauv qhov hnav-tiv taus ntawm cov hluav taws xob hluav taws xob hluav taws xob thiab cov khoom siv hluav taws xob hluav taws xob, xws li cov hluav taws xob, cov tshuab hluav taws xob, thiab cov khoom siv plua plav, txhawm rau txhim kho cov khoom siv lub neej thiab kev ua haujlwm zoo.

Machinery manufacturing:Siv los tsim cov khoom siv high-precision, siab hnav-tiv taus qhov chaw xws li bearings, lub zog, thiab kev taw qhia cov ntsia hlau los txhim kho kev ua haujlwm thiab kev ntseeg siab ntawm cov khoom siv tshuab.

Installation Thiab Maintenance

Installation txoj kev:Feem ntau kho nrog cov nplaum ua haujlwm. Ua ntej kev teeb tsa, xyuas kom meej tias lub hauv paus txheej yog tiaj thiab qhuav los txhim kho cov txiaj ntsig kev sib raug zoo.

Txoj kev tu:Rau kev tu txhua hnub, siv cov tshuaj ntxuav tes nruab nrab thiab cov ntaub mos muag los so, tsis txhob siv cov kua qaub los yog alkaline detergents kom tsis txhob ua rau qhov chaw ntawm thaj chaw puas.

Coal thiab Material Conveying System

Yeeb Nkab

Pob Zeb

Coal Mill

Kev tshem tawm plua plav Ssystem

Machinery Manufacturing

Ntau cov duab

Tuam txhab Profile

Shandong Robert Tshiab Khoom Co., Ltd.yog nyob rau hauv Zibo City, Shandong xeev, Suav teb, uas yog ib tug refractory cov ntaub ntawv ntau lawm puag. Peb yog ib lub tuam txhab niaj hnub uas koom nrog kev tshawb fawb thiab kev tsim kho, kev tsim khoom, muag, kiln tsim thiab kev tsim kho, thev naus laus zis, thiab xa tawm cov ntaub ntawv refractory. Peb muaj cov cuab yeej ua tiav, cov thev naus laus zis siab heev, muaj zog technical, cov khoom zoo heev, thiab lub koob npe zoo. Peb lub Hoobkas npog ntau tshaj 200 daim av thiab cov khoom tsim tawm txhua xyoo ntawm cov khoom siv refractory yog kwv yees li 30000 tons thiab cov ntaub ntawv tsis zoo yog 12000 tons.

Peb cov khoom tseem ceeb ntawm cov ntaub ntawv refractory muaj xws li:alkaline refractory khoom; aluminium silicon refractory cov ntaub ntawv; unshaped refractory khoom; rwb thaiv tsev thermal refractory cov ntaub ntawv; cov ntaub ntawv tshwj xeeb refractory; functional refractory cov ntaub ntawv rau nruam casting tshuab.

Cov lus nug nquag

Xav tau kev pab? Nco ntsoov mus saib peb lub rooj sab laj kev txhawb nqa rau cov lus teb rau koj cov lus nug!

Peb yog cov chaw tsim khoom tiag tiag, peb lub Hoobkas tshwj xeeb hauv kev tsim cov ntaub ntawv refractory rau ntau tshaj 30 xyoo. Peb cog lus tias yuav muab tus nqi zoo tshaj plaws, qhov zoo tshaj plaws ua ntej muag thiab kev pab cuam tom qab muag.

Rau txhua tus txheej txheem tsim khoom, RBT muaj kev ua tiav QC rau cov tshuaj muaj pes tsawg leeg thiab lub cev muaj zog. Thiab peb yuav kuaj cov khoom, thiab daim ntawv pov thawj zoo yuav raug xa nrog cov khoom. Yog tias koj muaj cov cai tshwj xeeb, peb yuav sim peb qhov zoo tshaj plaws kom haum lawv.

Nyob ntawm seb muaj pes tsawg, peb lub sijhawm xa khoom txawv. Tab sis peb cog lus tias yuav nkoj sai li sai tau nrog lav zoo.

Tau kawg, peb muab cov qauv dawb.

Yog lawm, tau kawg, txais tos tuaj xyuas RBT tuam txhab thiab peb cov khoom.

Tsis muaj kev txwv, peb tuaj yeem muab cov lus qhia zoo tshaj plaws thiab kev daws teeb meem raws li koj qhov xwm txheej.

Peb tau ua cov ntaub ntawv refractory rau ntau tshaj 30 xyoo, peb muaj kev txhawb zog thiab kev nplua nuj, peb tuaj yeem pab cov neeg siv khoom tsim cov kilns sib txawv thiab muab kev pabcuam ib zaug.